Outlet arrangement for down-hole separator

a separator and outlet arrangement technology, applied in the direction of separation process, drilling pipe, borehole/well accessories, etc., can solve the problems of water entering the oil phase and oil entering, and the residence time alone is not enough, so as to facilitate the coalescing and migration of smaller droplets, the effect of decreasing the cross sectional area and increasing the total residence tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

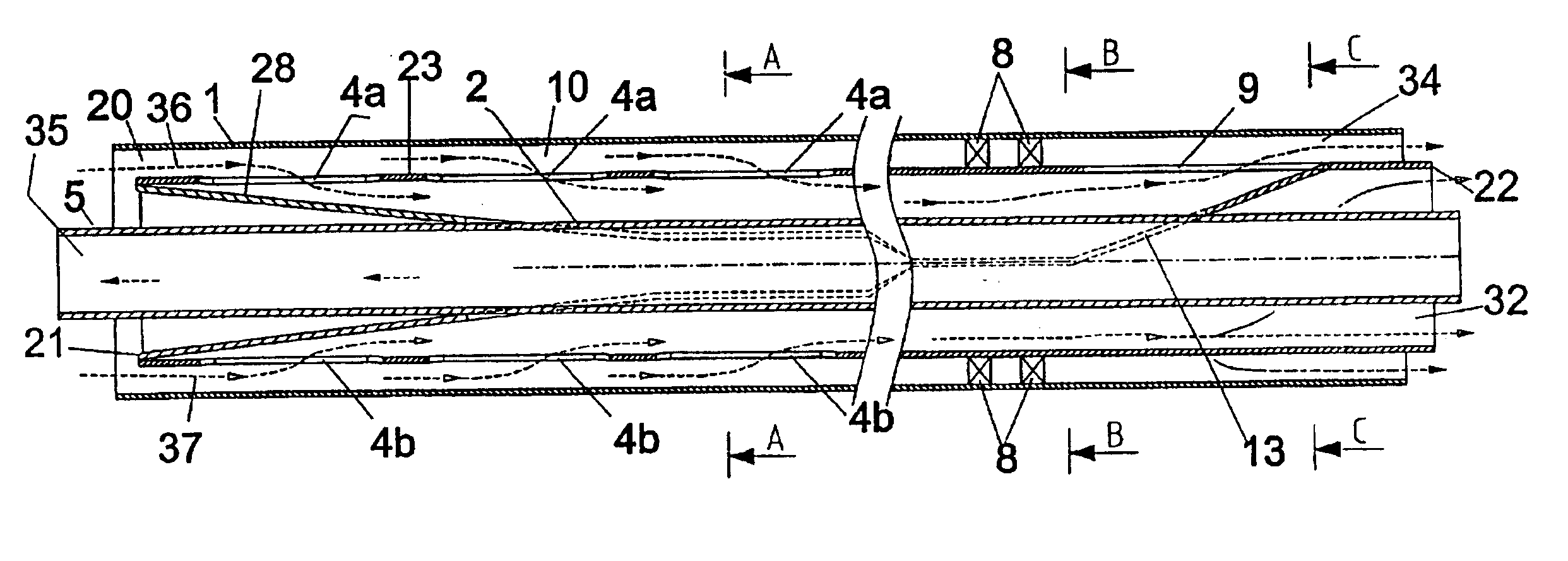

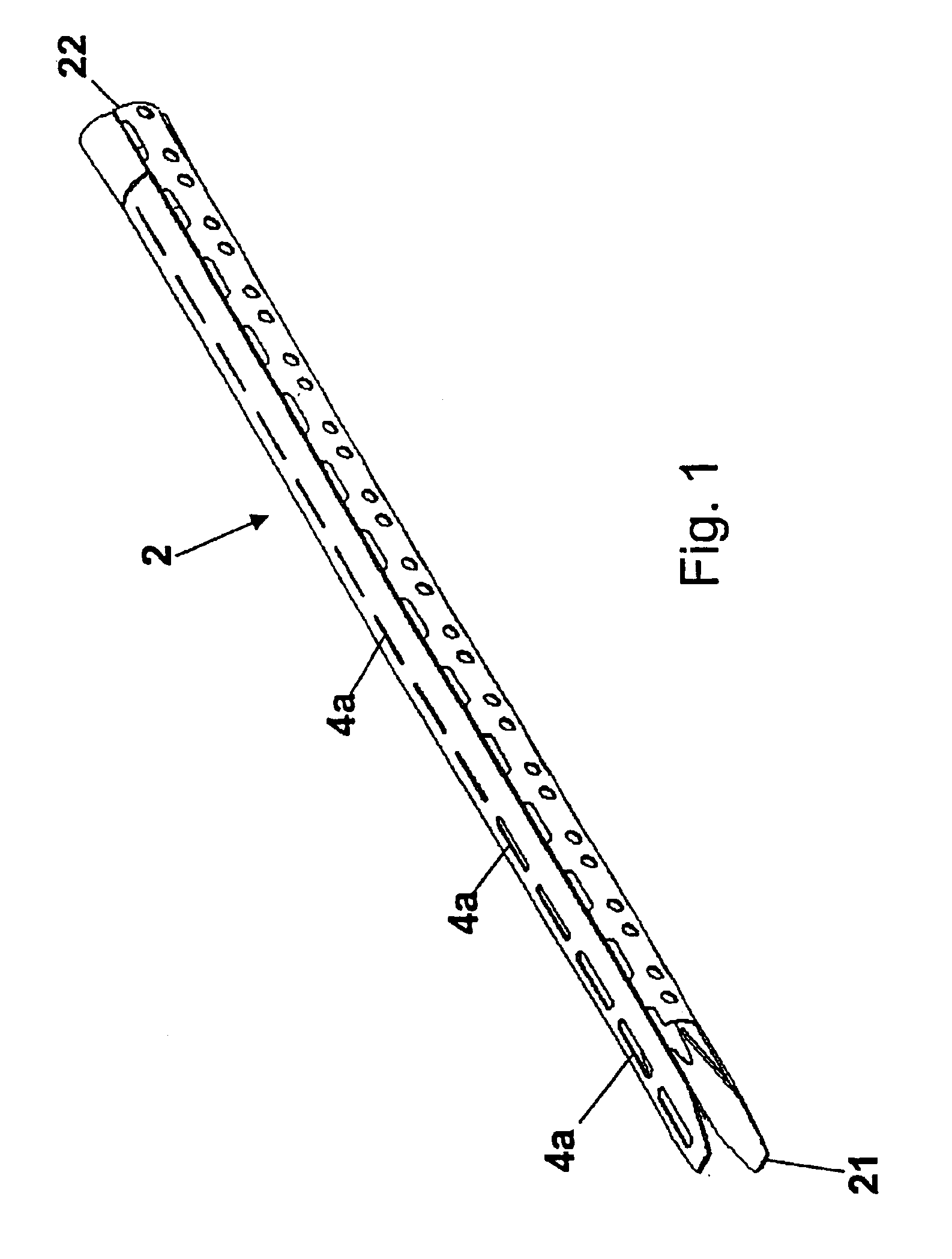

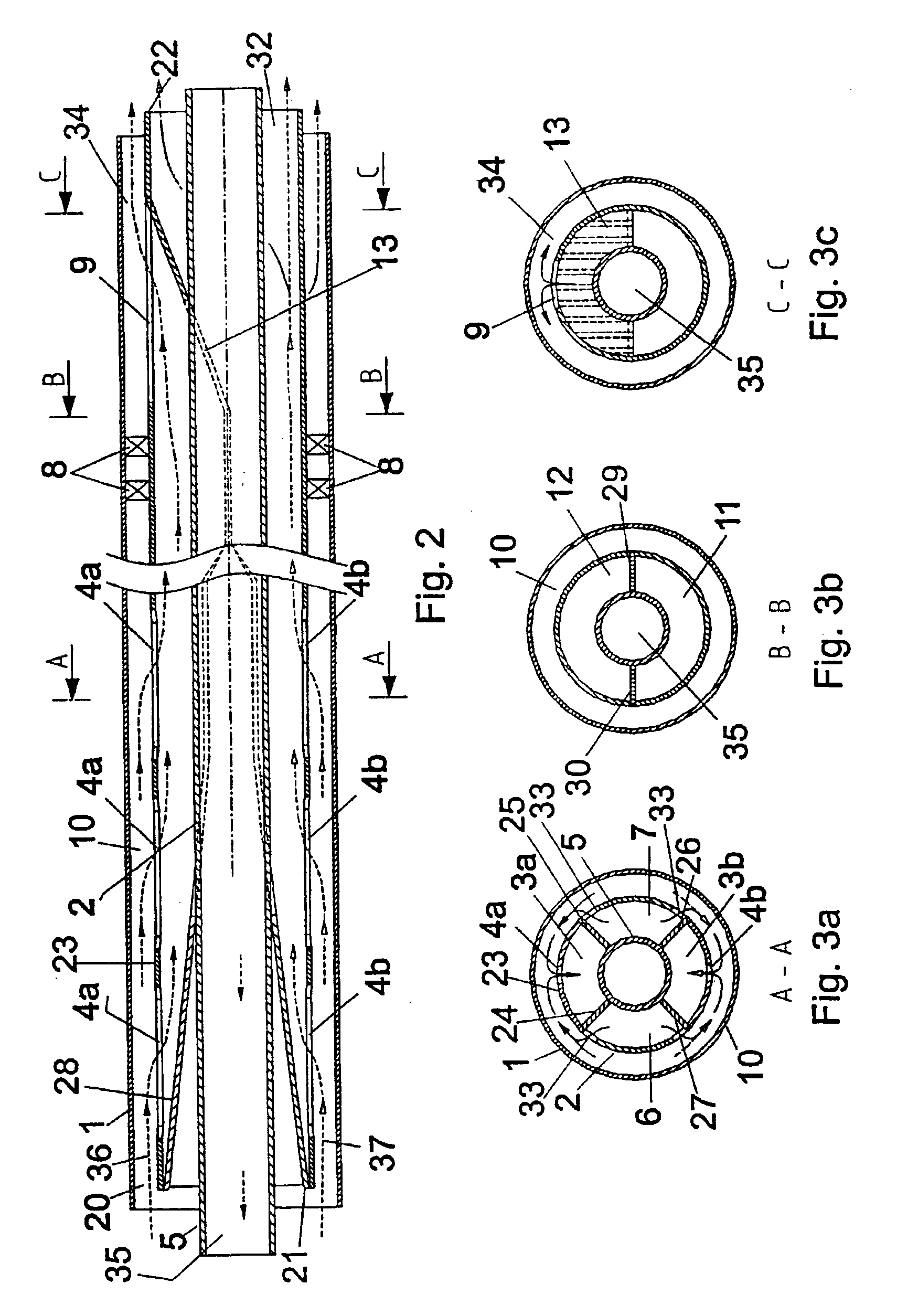

FIGS. 2 and 3a, b, and c show a longitudinal and transverse sections respectively through part of a liquid-liquid separator according to the present invention and including the outlet arrangement shown in FIG. 1. The separator has a high length to diameter ratio.

The separator comprises a separator wall 1 tubularly enclosing a separator chamber 20. An outlet arrangement 2 is provided inside the separator chamber 20. The outlet arrangement 2 is positioned along the longitudinal axis of the separator chamber 20, and extends over a length of e.g. 2-4 meters at the downstream end of the separator.

The outlet arrangement 2 has an outer end 21 facing the upstream direction and an inner end 22 that is connected to transport conduits outside the separator (not shown). The outlet arrangement further comprises an outer wall 23 that forms a pipe having approximately the same cross section along the length of the outlet arrangement 2. An annulus 10 is defined between the separator wall 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com