A kind of microfiltration membrane and process method of using microfiltration membrane to purify coal tar raw material

A process method and microfiltration membrane technology, which are applied in the field of coal tar purification and treatment, can solve problems such as the inability to achieve high-yield purification of coal tar, and achieve the effects of avoiding the fraction cutting process, reducing the probability of coking and corrosion, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

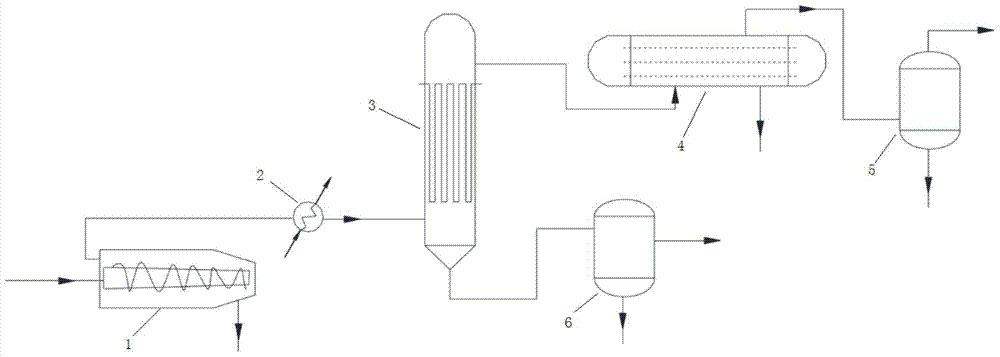

Image

Examples

Embodiment 1

[0039] The parameters of raw coal tar are: QI: 15000ppm; density: 1030kg / m 3 ; Metal: 250PPm; Salt content 84mg / L; Water: 1.8%.

[0040] High-speed centrifugation operating conditions: operating temperature: 82°C; rotating speed: 3000r / min.

[0041] Microfiltration demulsification operating conditions: microfiltration membrane precision: 0.5μm; temperature: 120°C; operating pressure: 0.8MPa.

[0042] Operating conditions for electrical desalination: electric field strength: 1000V / cm; metal removal agent: 70μg / g; operating temperature: 135°C; operating pressure: 0.3MPa.

[0043] Energy consumption: 50kw / t.

[0044] Parameters of purified coal tar: Density: 1029kg / m 3 ; QI: 20ppm; metal: 30ppm; salt content: 4mg / L; water: 0.15%; raw material yield: 95.8%.

Embodiment 2

[0046] The parameters of raw coal tar are: QI: 6000ppm; density: 1016kg / m 3 ; Metal: 200PPm, salt content 60mg / L; Water: 2.2%.

[0047] High-speed centrifugation operating conditions: operating temperature: 80°C; rotating speed: 2200r / min.

[0048] Microfiltration demulsification operating conditions: microfiltration membrane precision: 0.2μm; temperature: 110°C; operating pressure: 0.5MPa.

[0049] Operating conditions for electrical desalination: electric field strength: 800V / cm; metal removal agent: 50μg / g; operating temperature: 130°C; operating pressure: 0.3MPa.

[0050] Energy consumption: 50kw / t.

[0051] Parameters of purified coal tar: Density: 1016kg / m 3 ; QI: Not detected; Metal: 20ppm; Salt content: 1mg / L; Water: 0.12%; Raw material yield: 96.5%.

Embodiment 3

[0053] The parameters of raw coal tar are: QI: 4000ppm; density: 1016kg / m 3 ; Metal: 220PPm; Salt content 75mg / L; Water: 2.0%.

[0054] High-speed centrifuge operating conditions: operating temperature: 80°C; rotating speed: 2600r / min.

[0055] Microfiltration demulsification operating conditions: microfiltration membrane precision: 0.3μm; temperature: 120°C; operating pressure: 0.6MPa.

[0056] Operating conditions for electrical desalination: electric field strength: 1000V / cm; metal removal agent: 60μg / g; operating temperature: 135°C; operating pressure: 0.3MPa.

[0057] Energy consumption: 50kw / t.

[0058] Parameters of purified coal tar: Density: 1016kg / m 3 ; QI: 10ppm; metal: 25ppm; salt content: 1mg / L; water: 0.1%; raw material yield: 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com