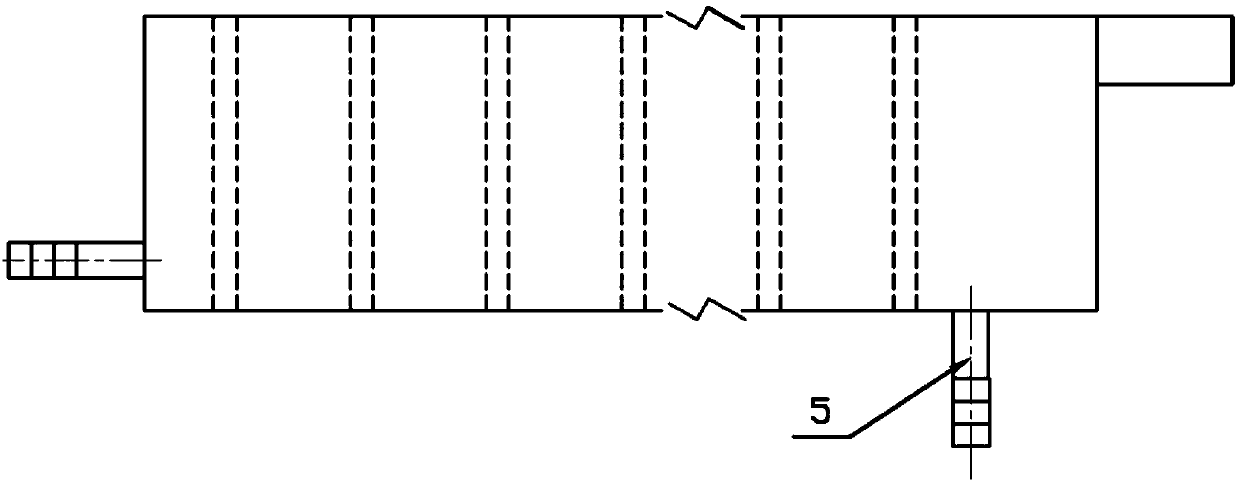

Device for demulsifying oil-in-water emulsion under action of direct current electric field

A technology of direct current electric field and demulsification device, which is applied in the direction of grease/oily substance/floating matter removal device, magnetic field/electric field water/sewage treatment, water pollutants, etc., and can solve poor adaptability, low efficiency, large footprint, etc. Problems, to achieve the effect of increasing the chance of collision coalescence, speeding up movement, and promoting rapid migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

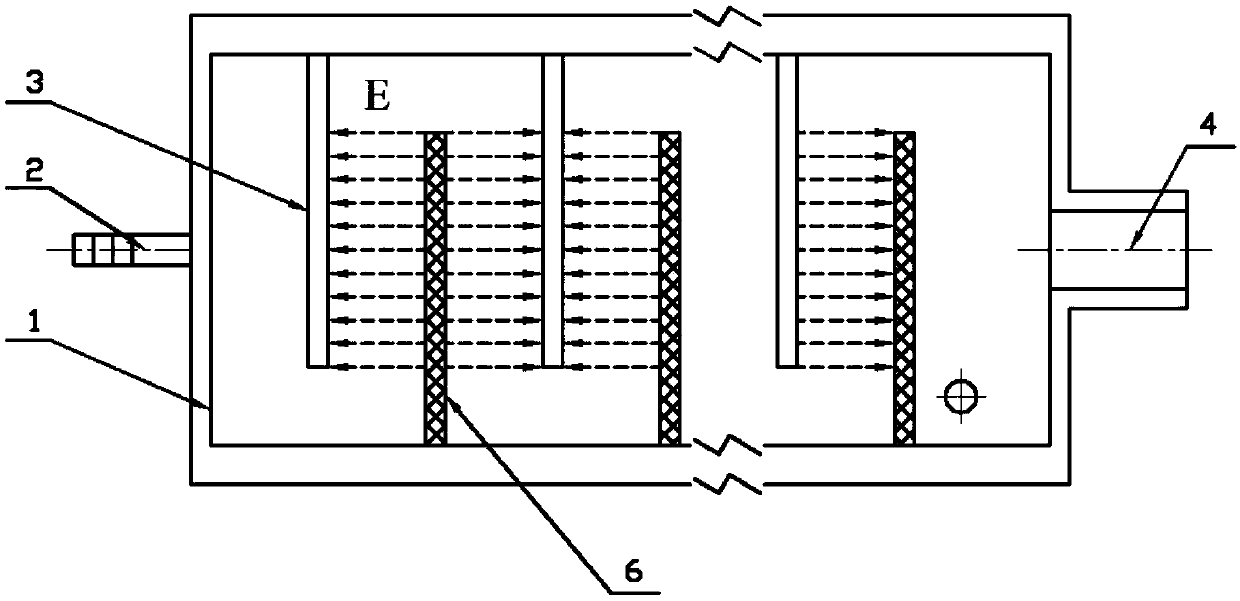

[0040] The surface styles on both sides of the cathode plate 3 and the anode plate 6 are smooth planes, the distance between two adjacent plates (collectively referred to as the cathode plate 3 and the anode plate 6) is 25 mm, and the plate height is 50 mm. The board is not powered, inject 2L oil-in-water emulsion (Mobil hydraulic oil DTE-24) into the tank 1, the oil content is 0.45% vol, draw the emulsion out through the water outlet 5, and then re-enter the tank 1 through the water inlet 2 When the thickness of the oil layer on the upper layer of the emulsion reaches more than 5mm, adjust the flow rate so that the oil after demulsification is discharged from the oil outlet 4, so as to realize oil-water separation; continuous treatment for 150min under the condition of flow rate of 110ml / min, Finally, the demulsification rate was measured to be 36.77%.

Embodiment 2

[0042] The cathode plate 3 and the anode 6 are respectively connected to the positive pole and the negative pole of the power supply to form a DC electric field, the applied voltage is 20V, and the distance between two adjacent plates (the general designation of the cathode plate and the anode plate) is 25mm, The plate height is 50mm, the cathode plate 3 and the anode plate 6 are flat plates, 2L oil-in-water emulsion (Mobil hydraulic oil DTE-24) is injected into the box 1, the oil content is 0.45% vol, and the emulsion is passed through the outlet The water port 5 is pulled out, and then re-enters the tank 1 through the water inlet 2 to realize circulation. After the power is turned on, the demulsification starts. The oil port 4 is discharged to realize the separation of oil and water; the flow rate is 110ml / min and the treatment is continuous for 150min. Finally, the demulsification rate is 98.0%.

Embodiment 3

[0044]The cathode plate 3 and the anode 6 are respectively connected to the positive and negative poles of the power supply to form a DC electric field, the applied voltage is 20V, and the distance between two adjacent plates (the cathode plate 3 and the anode plate 6 are collectively referred to as) is 50mm, the plate height is 50mm, the cathode plate 3 and the anode plate 6 are both sinusoidal corrugated plates, 2L oil-in-water emulsion (Mobil hydraulic oil DTE-24) is injected into the box 1, and the oil content is 0.45% vol. The emulsion is pumped out through the water outlet 5, and then re-enters the tank 1 through the water inlet 2 to realize circulation. After the power is turned on, the demulsification starts. When the thickness of the oil layer on the upper layer of the emulsion reaches 5mm or more, adjust the flow rate so that The oil is discharged from the oil outlet 4, thereby realizing the separation of oil and water; the flow rate is 110ml / min and the continuous tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com