Bricklaying structure, bricklaying method, and brick manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

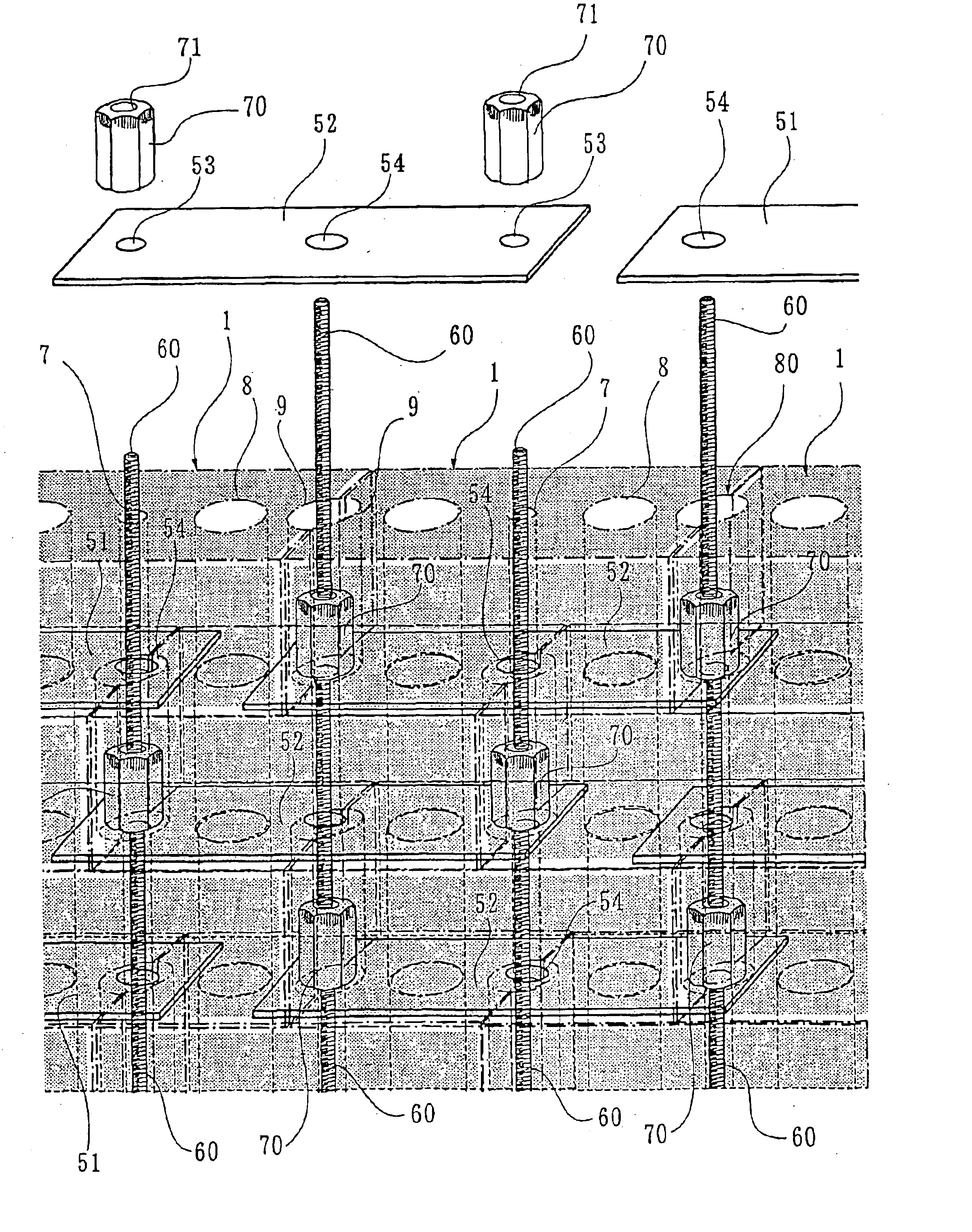

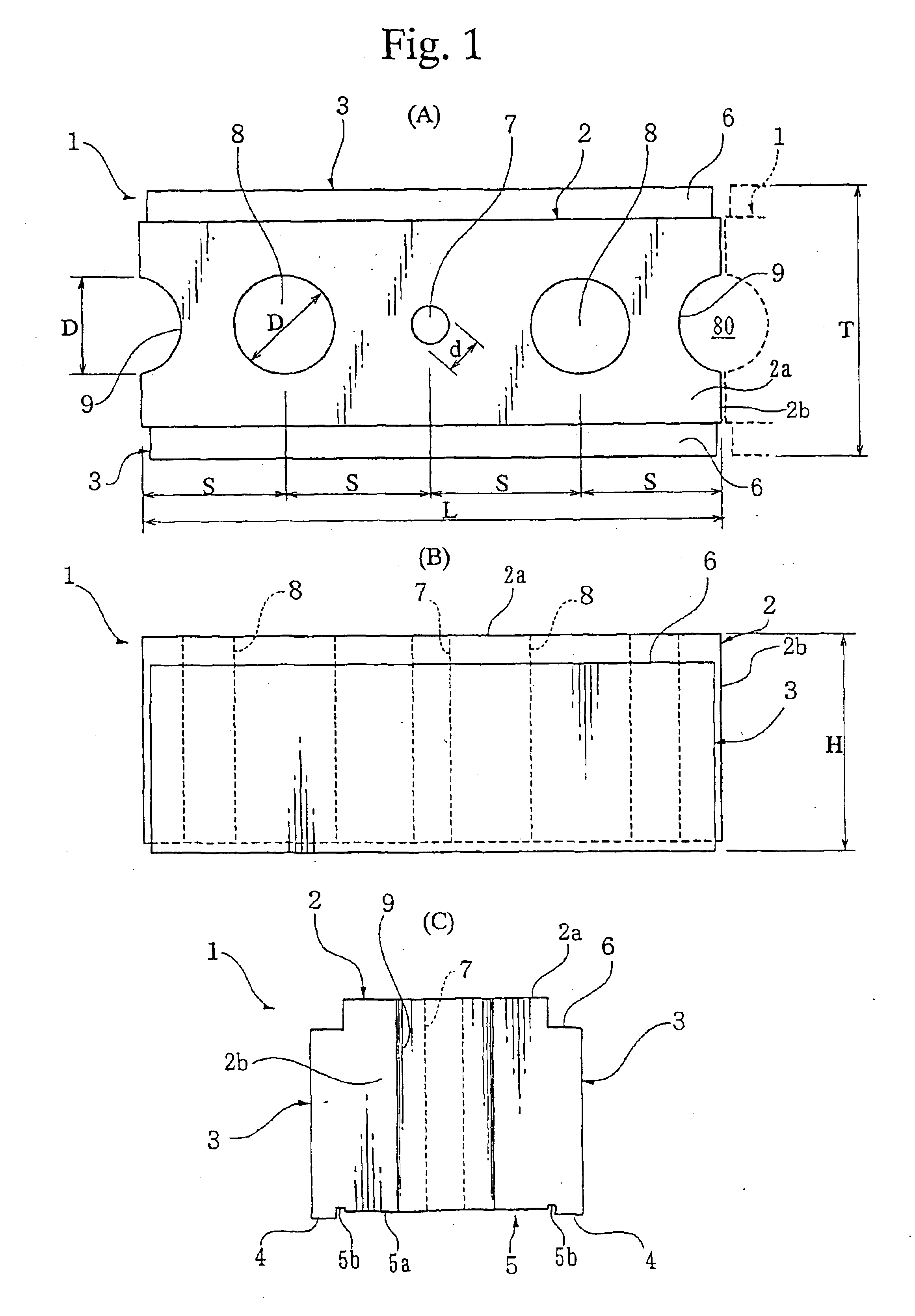

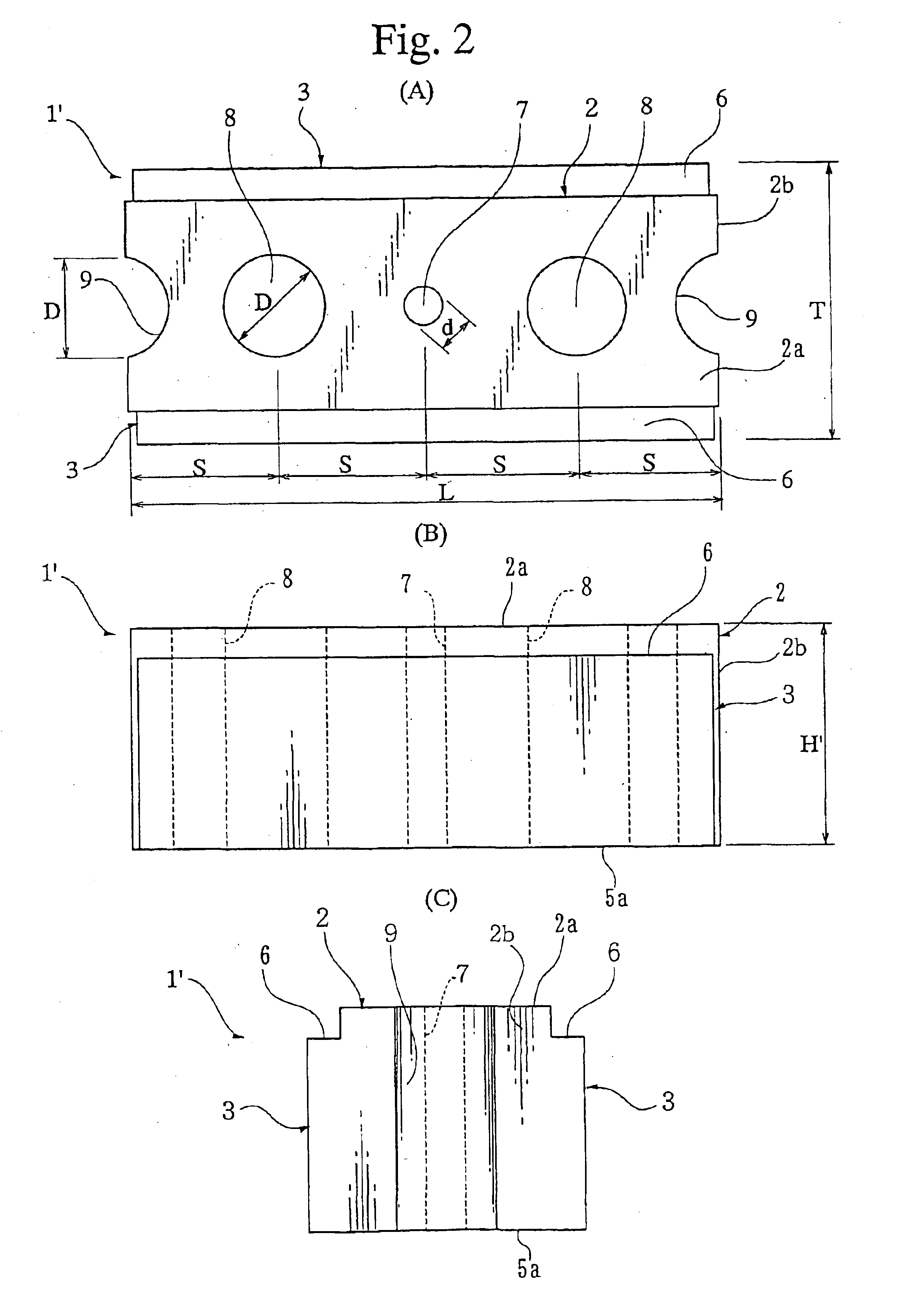

[0039]With reference to the attached drawings, preferred embodiments of the present invention is described hereinafter.

[0040]Various kinds of profiles of bricks are illustrated in plan, front elevational and side elevational views of FIGS. 1 to 4, and the profile of metallic plates inserted between the vertically adjacent bricks are illustrated in a plan view of FIG. 5. A profile of a regular brick is illustrated in FIG. 1, and a profile of a flat-bottom-type brick is illustrated in FIG. 2. In FIGS. 3 and 4, there are shown profiles of irregular or purpose-made bricks used for corner parts, such as an external corner, an internal corner or a columnar configuration.

[0041]The regular brick as shown in FIG. 1 is an integrally formed product made from clay by high temperature baking, which has a body portion 2 and offset portions 3 on both sides thereof. The approximate length, width and height are set to be, e.g., 240 mm, 85 mm and 85 mm, respectively. The body portion 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com