Compact structure for automatically filling solid pharmaceutical product packages

a technology of automatic packaging and pharmaceutical products, applied in the direction of packaging goods, liquid handling, transportation and packaging, etc., can solve the problems of unsatisfactory existing machinery, less space available for a substantial amount of machinery, and more difficult to achieve horizontal displacement of products into desired locations, etc., to achieve high-speed operation and ease of operation. the effect of the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

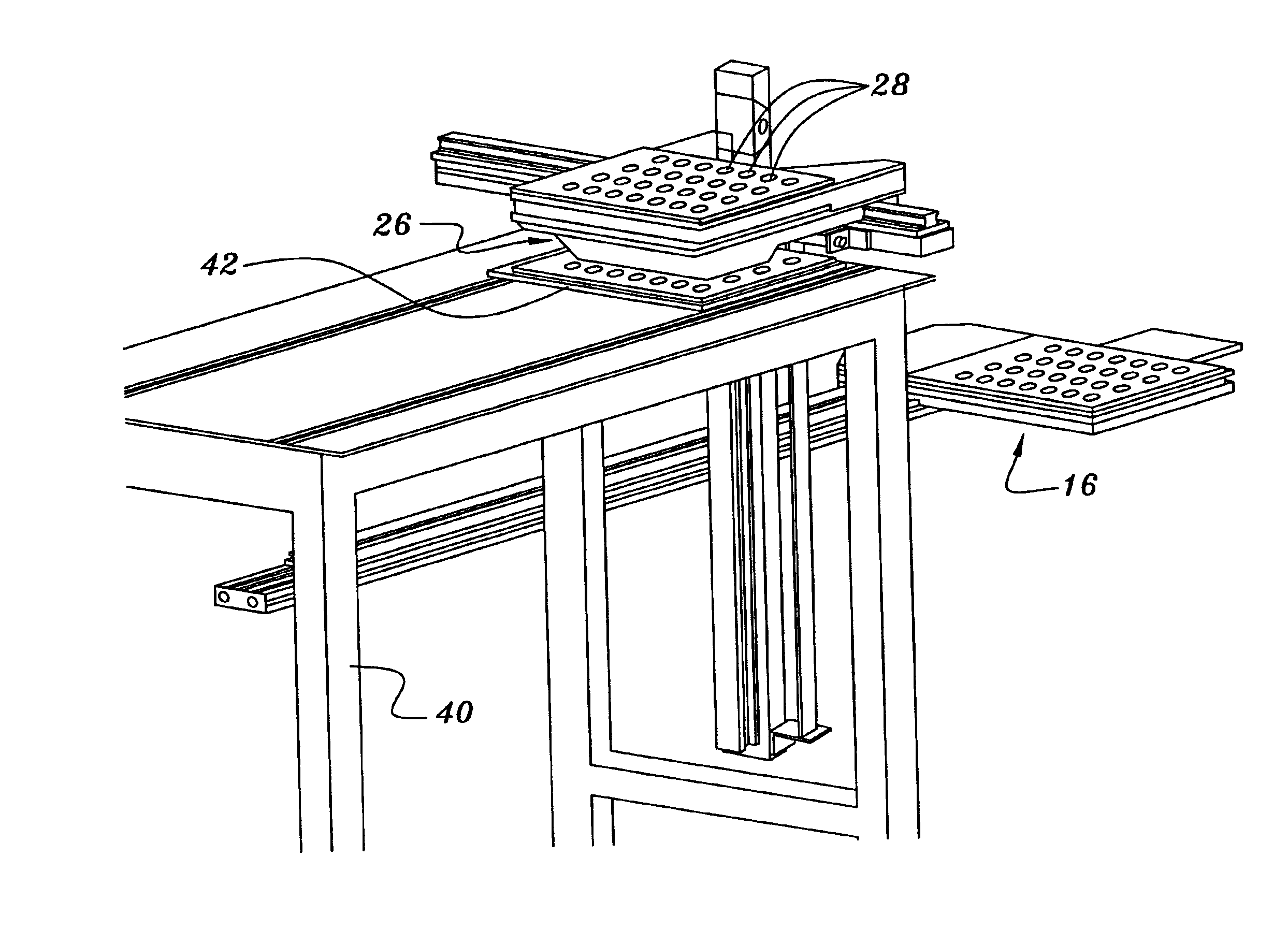

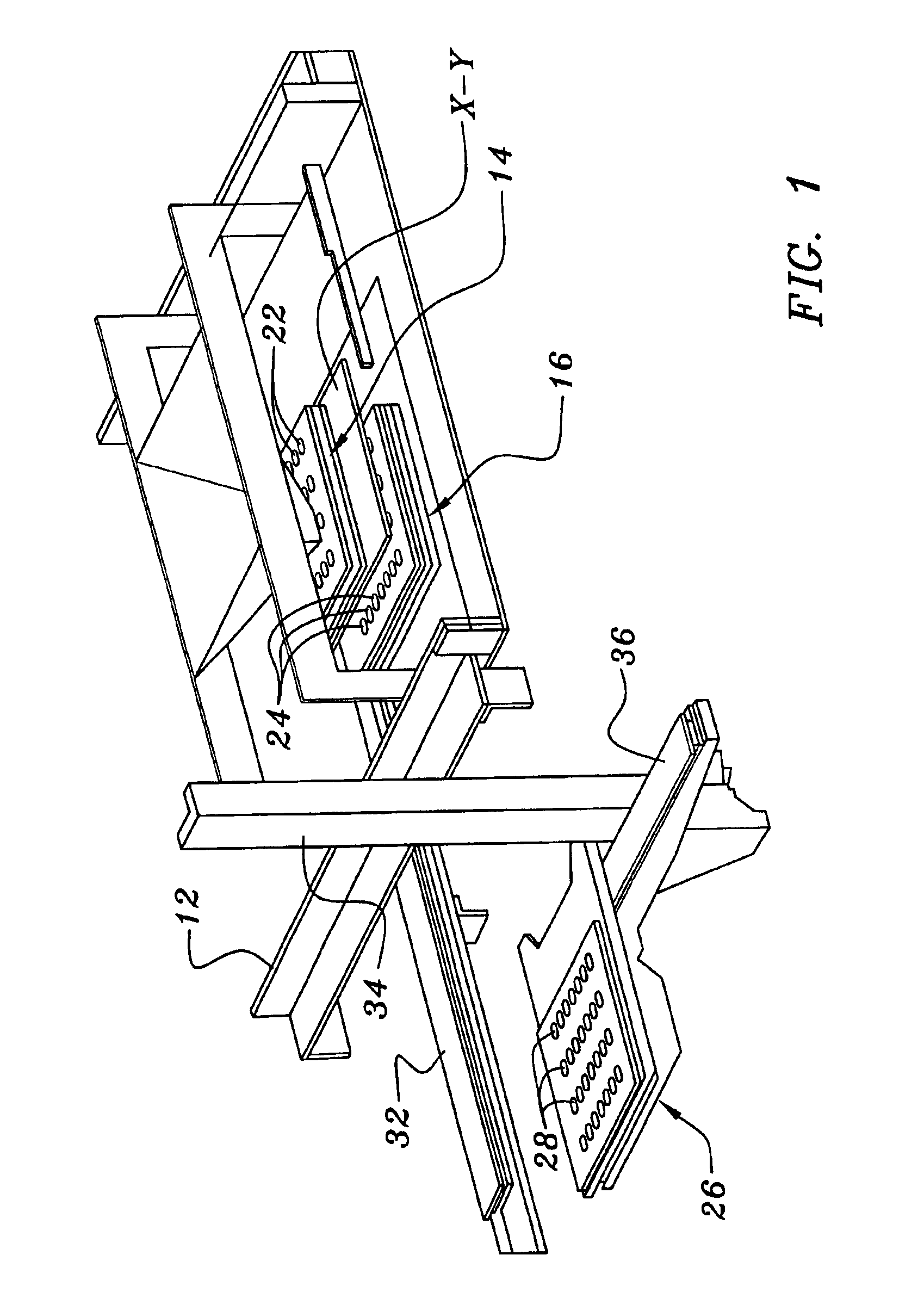

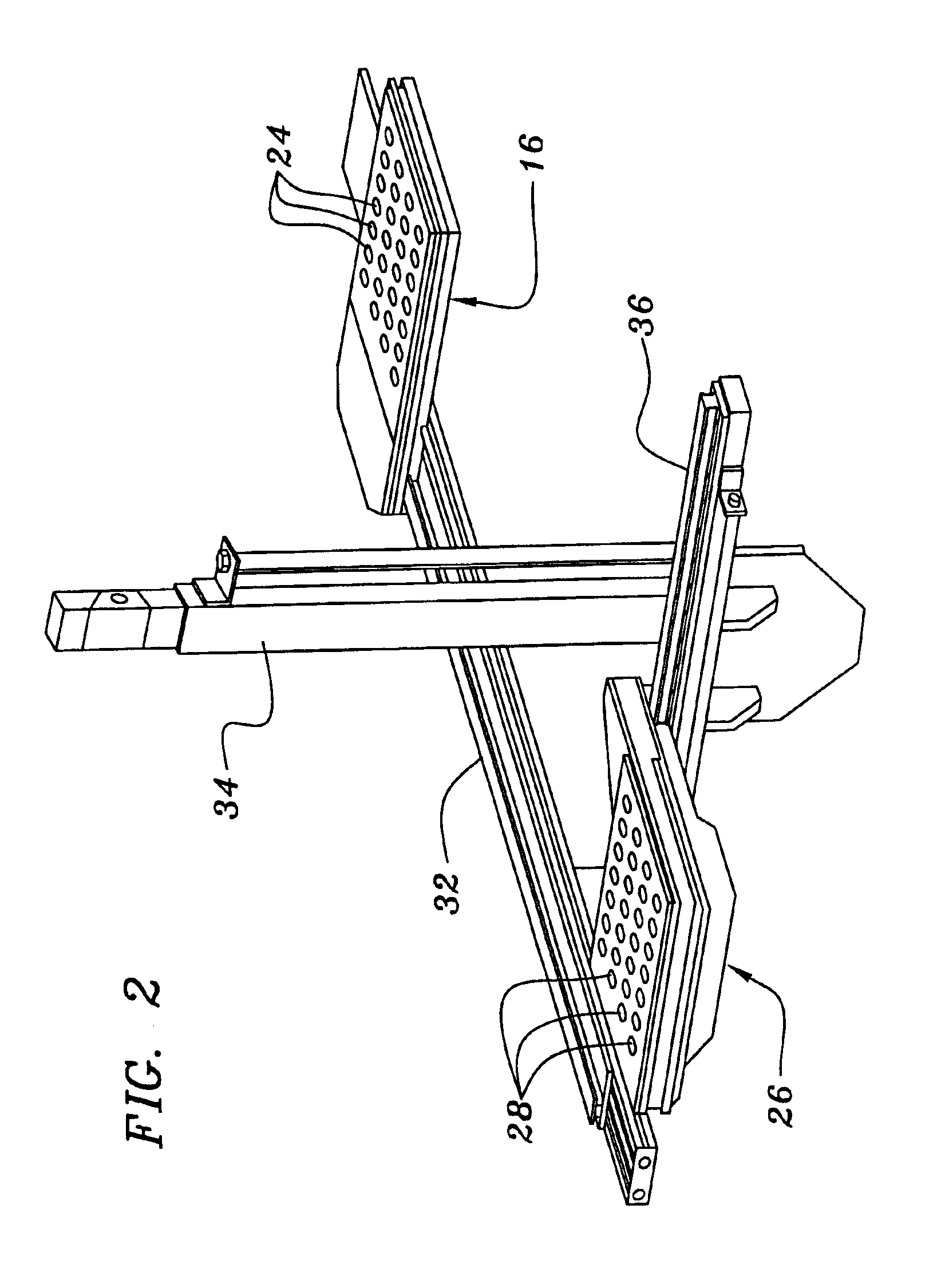

[0022]FIG. 1 illustrates a first preferred exemplary embodiment of the present invention which is shown generally at 10. As illustrated in FIG. 1, a support framework 12 provides a mechanical support for receiving and / or supporting a structure that includes a temporary storage member 14 that is movable in at least 2 axis of displacement. The tray or initial temporary storage member 14 is preferably comprised of a plurality of solid pharmaceutical product cavities arranged in a matrix that corresponds to the arrangement of blister package cavities of a package to be filled. The tray or initial temporary storage member is also known as the upper temporary storage member and is displaced in xy coordinates to selectively locate individual ones of the cavity members beneath a funnel that receives solid pharmaceutical product members that are deposited from a dispensing device or canister.

[0023]A plurality of solid pharmaceutical product dispensers or canisters are arrayed in a cabinet. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com