Method of reinforcing an automobile structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

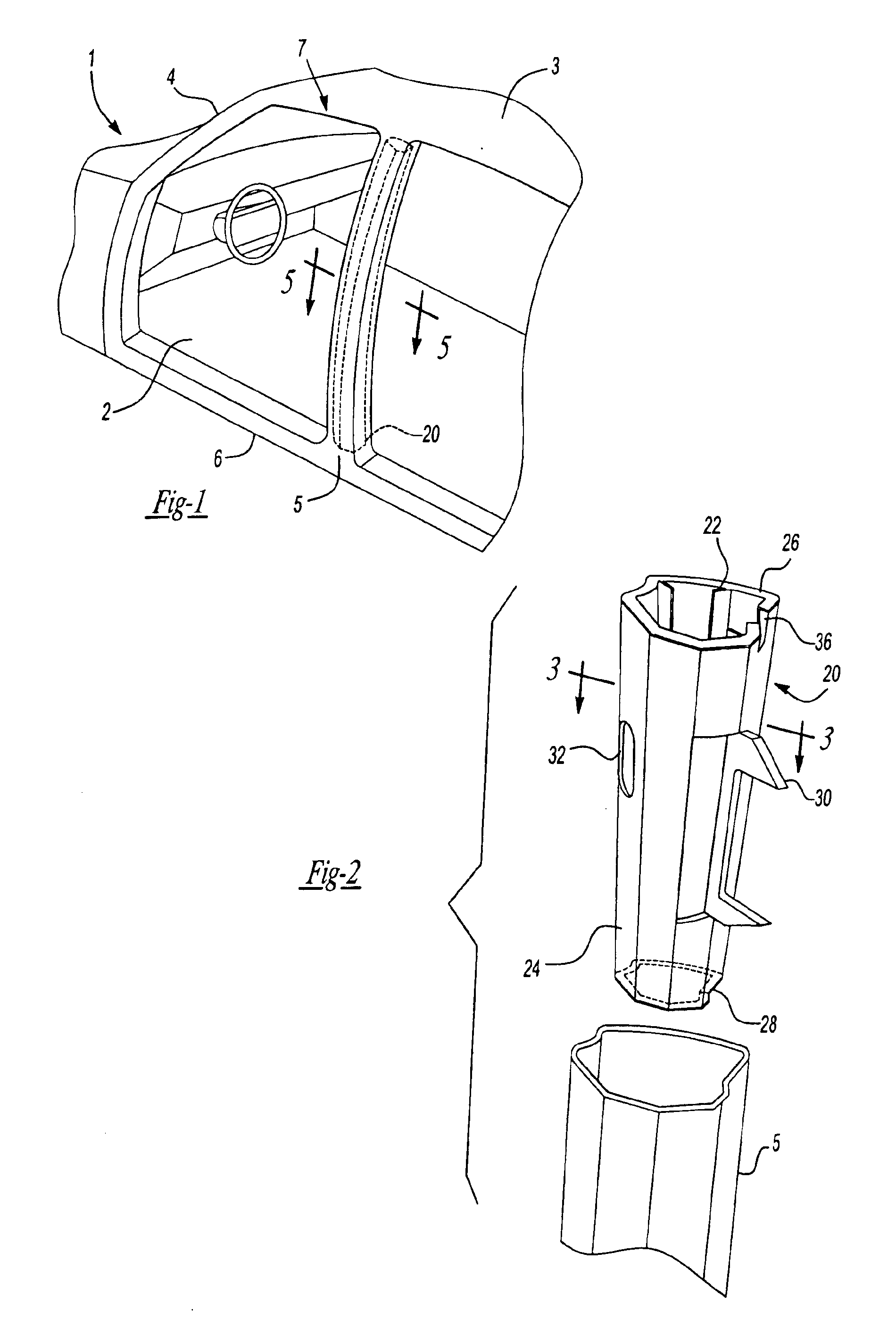

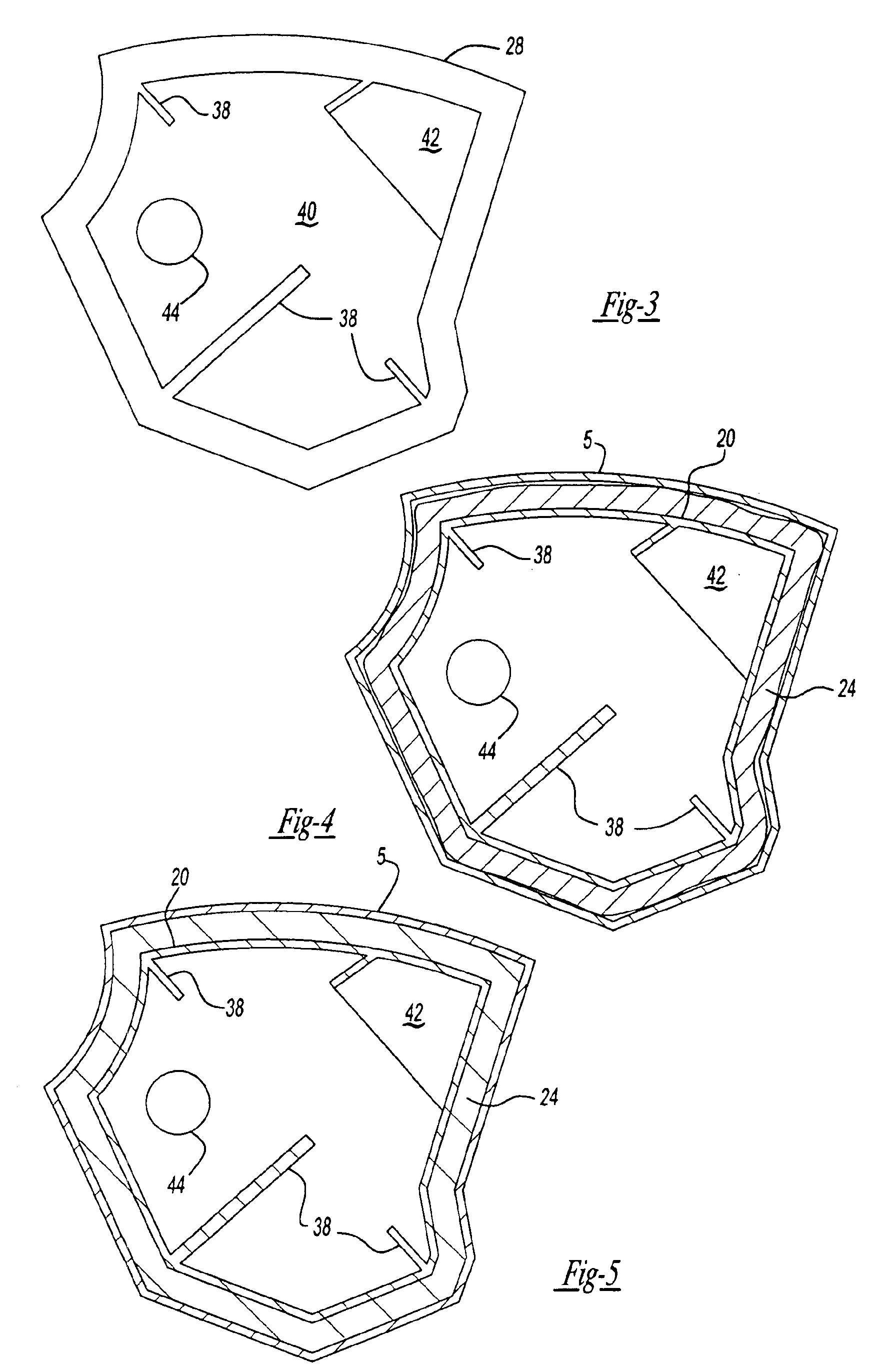

[0017]FIG. 2 shows a reinforced sleeve 20 formed in accordance with the teachings of this invention. The sleeve 20 includes a carrier 22 and a reinforcing medium 24 supported by the carrier 22.

[0018]The carrier 22 is an elongated member having open end portions 26, 28. At the end 26, the carrier 22 includes a U-shaped notch 36 and an elongated opening 32, each of which aligns with mating components on an automobile frame, or alternatively permits venting of the sleeve 20. At the opposite end 28, the carrier 22 defines an opening (not shown), which also aligns with mating components of an automobile frame or alternatively permits venting of sleeve 20. The exterior surface of the carrier 22 supports an outwardly extending C-shaped bracket 30 between the end portions 26, 28.

[0019]Internally, the carrier 22 is reinforced by an interior plate 40, as best seen in FIG. 3. The plate 40 is located approximately at the center portion of the carrier 22, and includes two openings 42, 44 for per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Foam | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com