Boiling heat transfer torpedo

a heat transfer and torpedo technology, applied in special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of limiting the performance of undersea vehicles such as torpedoes, limiting the speed and range of torpedoes, and creating drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

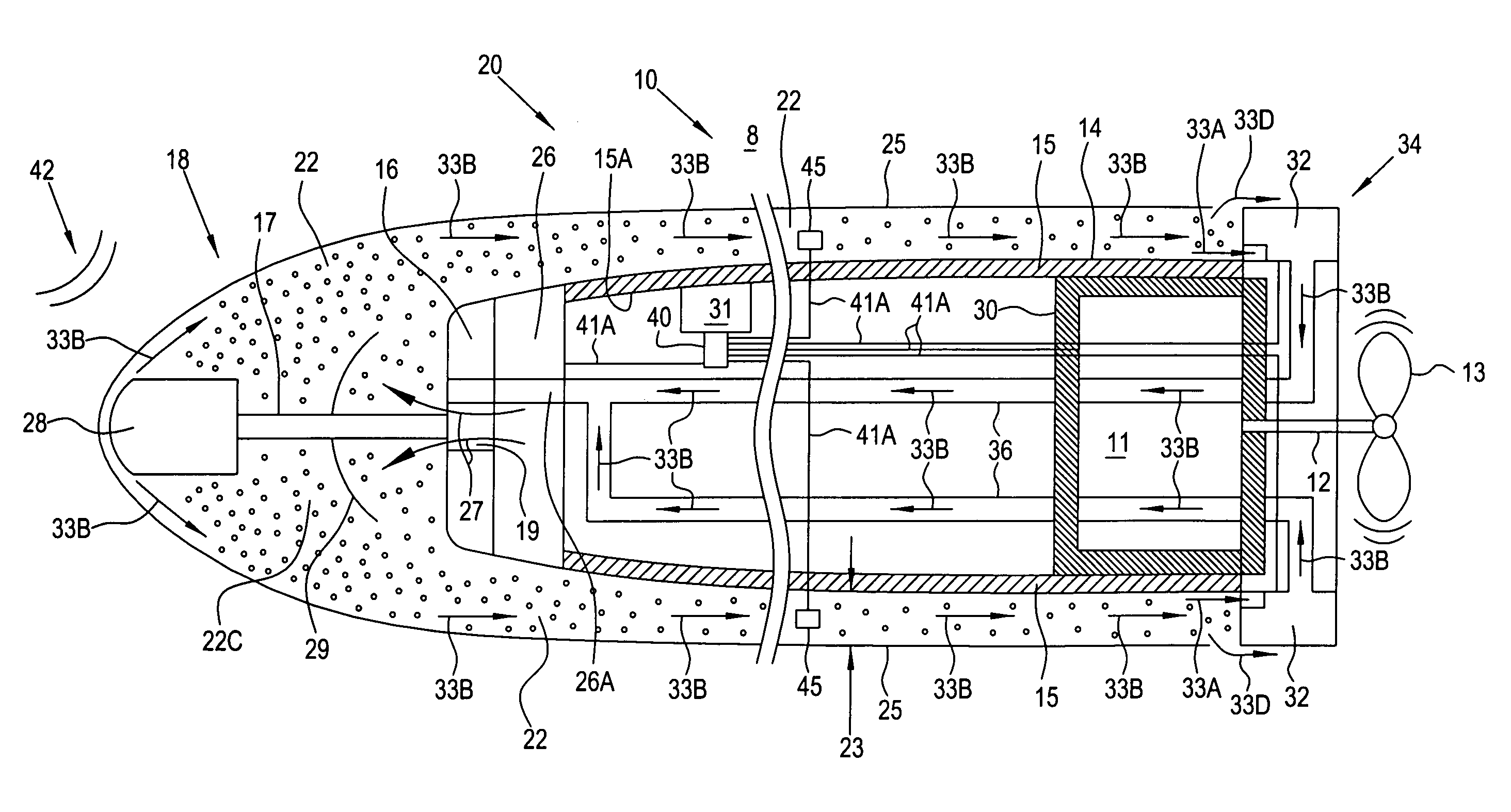

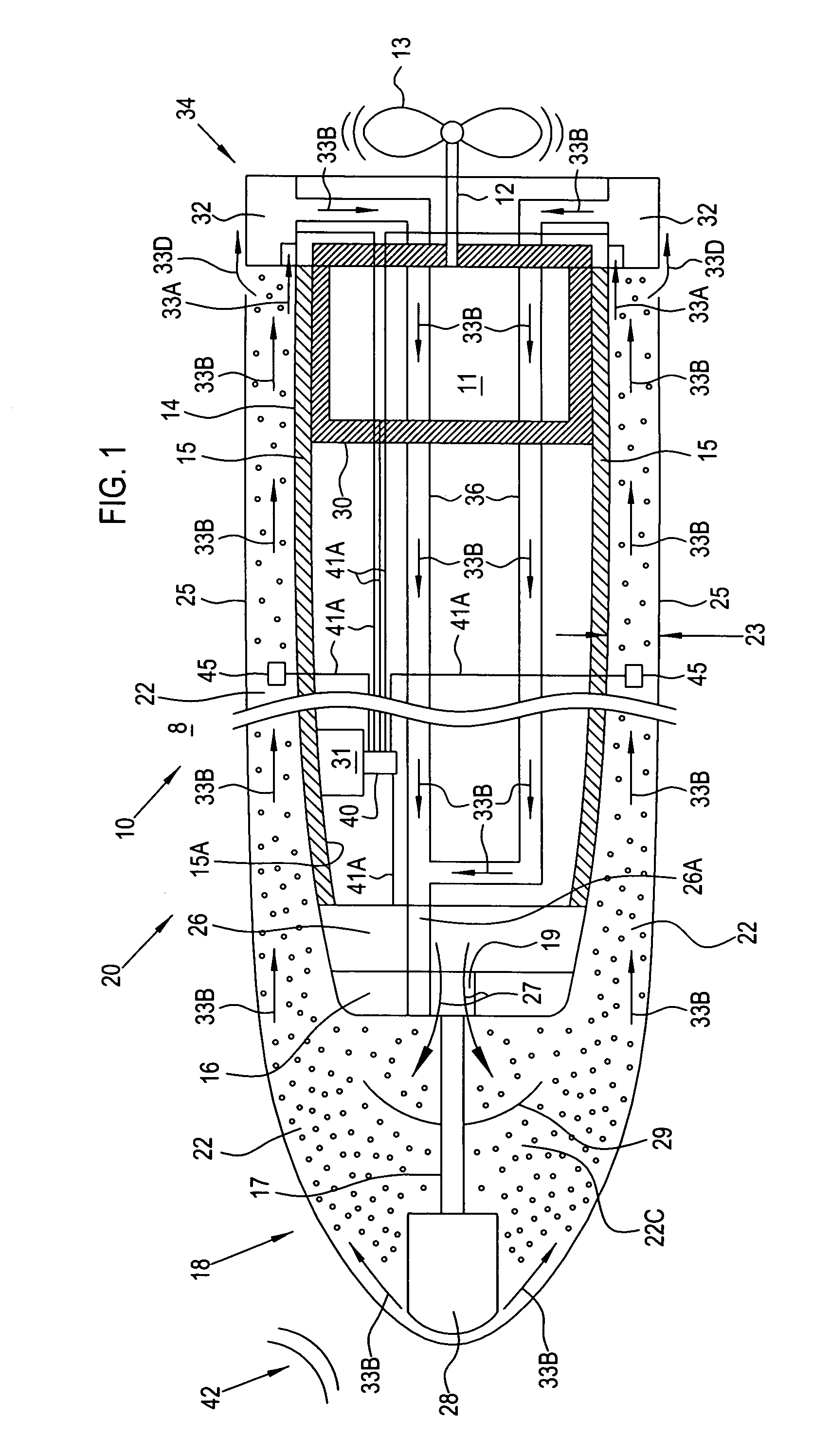

[0020]Referring to FIG. 1 of the drawings, a torpedo 10 has an internal thermal engine or motor 11 connected by a shaft 12 to one or more propellers 13 to propel torpedo 10 through ambient water 8 to a distant target. Engine 11 can be any of many well known proven designs that creates sufficient power to rotate interconnected propellers 13 for propulsive thrust and generates considerable amounts of waste heat as a by-product of operation. Engine 11 could also be a rocket or jet engine that produces significant waste heat. This waste heat is effectively coupled by heat transfer-ventilation system of the invention to an outer surface 14 of hull 15 of torpedo 10 to help create a cavity 22 to reduce drag between torpedo 10 and ambient water 8.

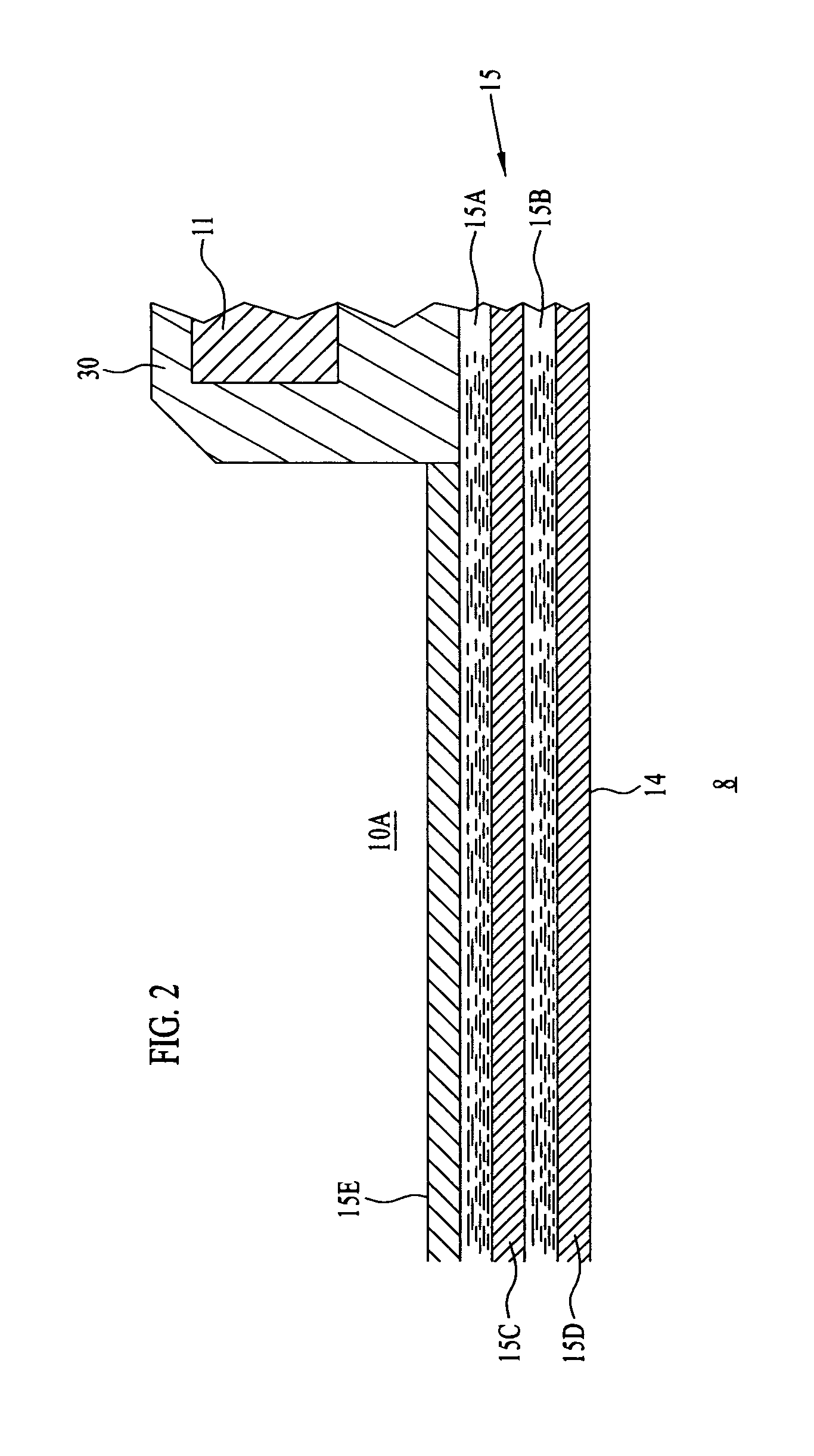

[0021]Referring also to FIG. 2, hull 15 can be made of layers 15A, 15B, of high heat capacity liquid or metal that are sandwiched within matrix layers 15C, 15D of highly conductive material. Hull 15 has an insulating layer 15E for thermal shielding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com