Use of cutting velocities for real time pore pressure and fracture gradient prediction

a cutting speed and fracture gradient technology, applied in seismology for waterlogging, instruments, borehole/well accessories, etc., can solve the problems of limited use of cuttings, no commercially available tools, and risk of gas kick/blowout, etc., to accurately predict pore pressure and fracture gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example i

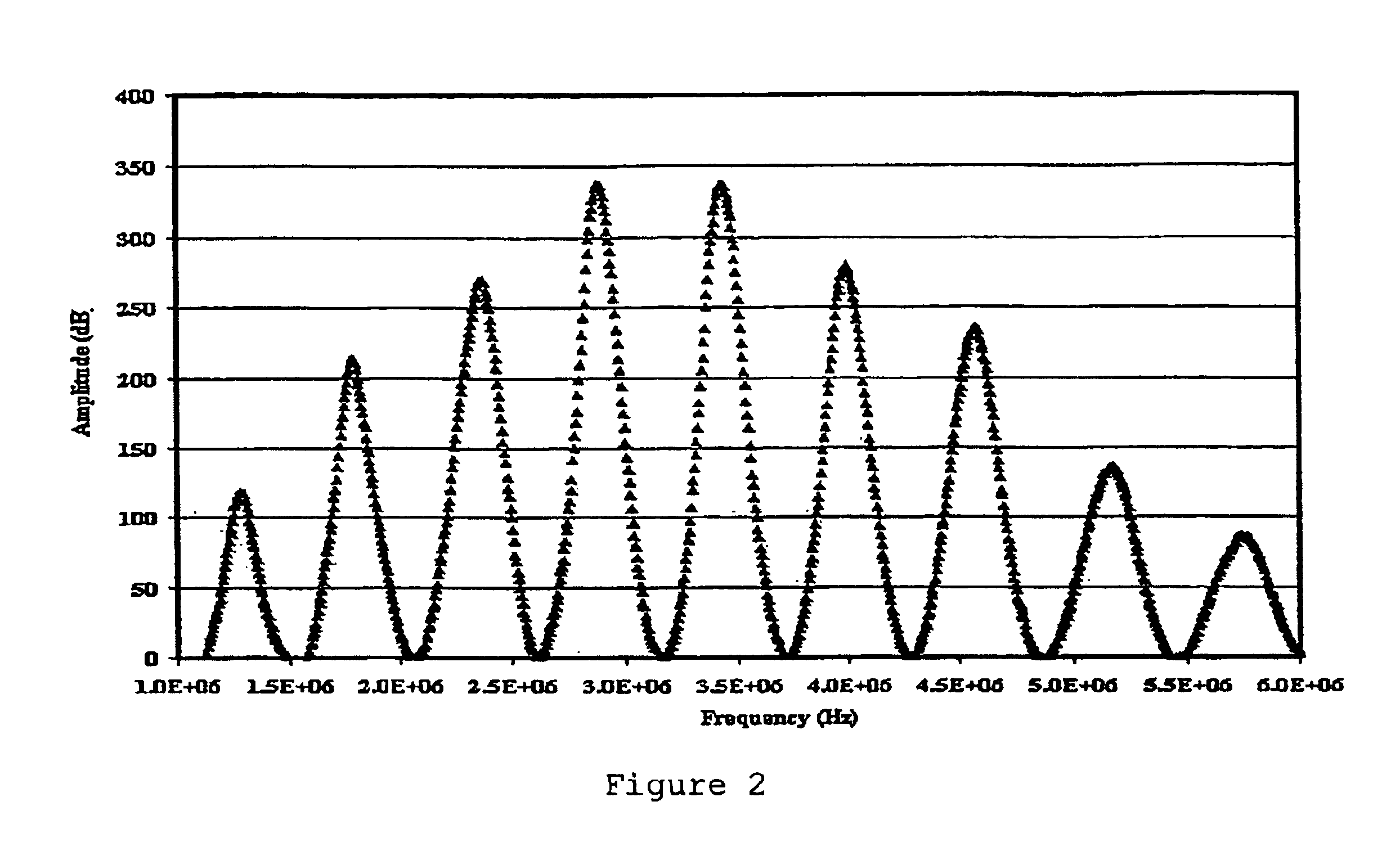

[0097]Reference materials were tested in the laboratory and at the rig site to verify the accuracy of the velocity measurement methodology (CWT) that is the source of the input data for the methodology discussed in this invention. Results of some reference experiments are shown in FIG. 3. The salt sample used in the measurement had an impurity in it. Therefore, two different Δf values were obtained corresponding to the pure halite and impurity, respectively. Resulting CWT velocity versus frequency indicates two different velocities based on the two different Δf values.

example ii

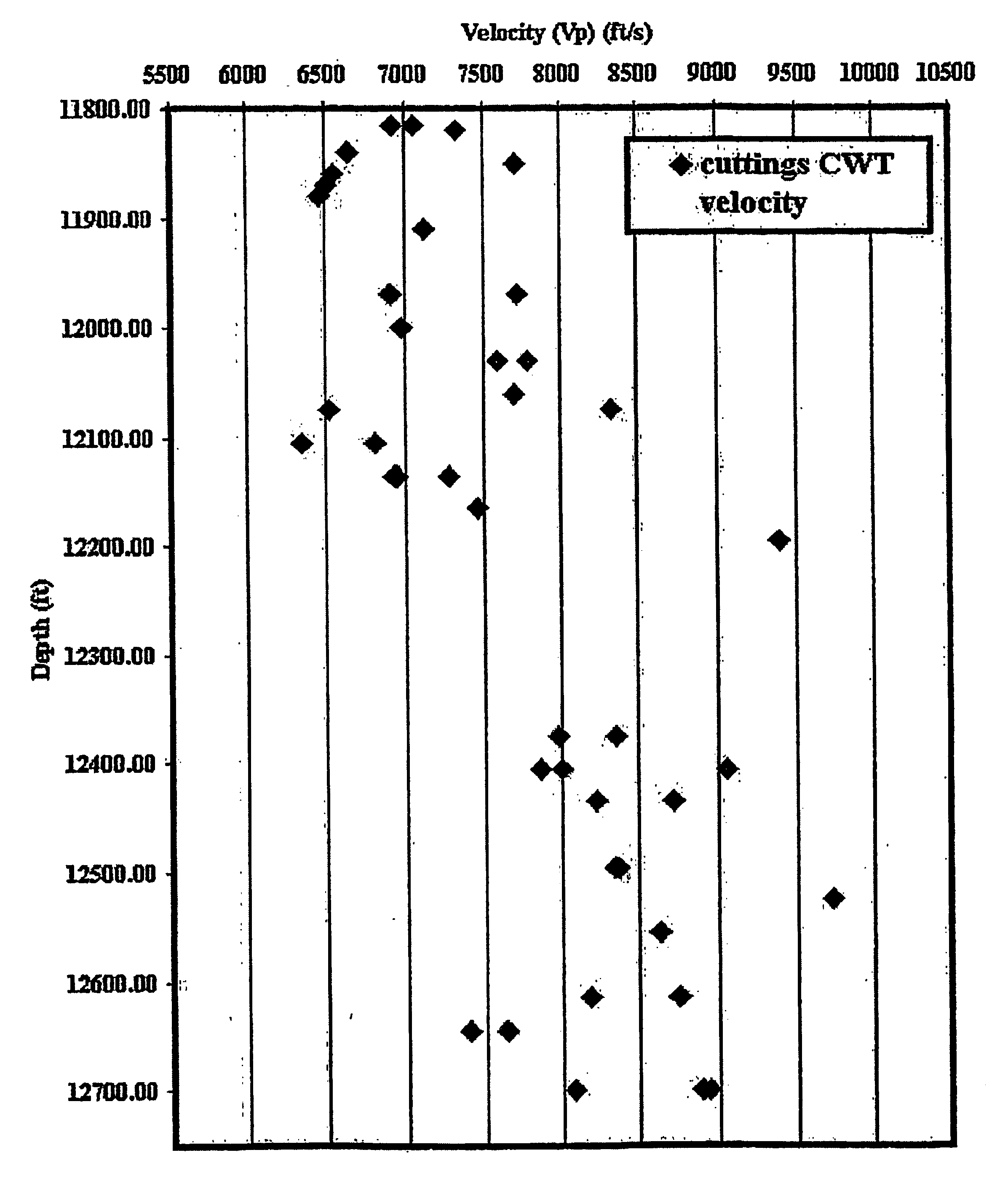

[0098]The tool was field tried at a Gulf of Mexico rig site and real time CWT measurements were conducted at a specific hole interval. During the drilling, sonic LWD was not run due to large hole size. Therefore, CWT velocities provided the only real time source while drilling for calibration of the pore pressure predicted from seismic data before drilling. The recorded velocity versus depth from the selected interval is shown in FIG. 4. Corresponding pore pressure and fracture gradient obtained from the CWT velocities presented in FIG. 4 and from the dielectric coefficient measurements using drill cuttings are shown in FIG. 5. After the interval was drilled, wireline sonic data was collected. A comparison of the wireline velocities and CWT velocities are presented in FIG. 6. The resulting pore pressure and fracture gradient comparison between seismic, wireline sonic, CWT velocities and DCM derived fracture gradient are summarized in FIG. 7. It is evident from FIG. 7 that the CWT an...

example iii

[0099]Cuttings from another Gulf of Mexico well have been used to predict pore pressure and fracture gradient using CWT velocities and DCM measurements. Predicted pore pressure and fracture gradient obtained from the velocities and DCM are presented in FIG. 8 along with log-derived pore pressure and fracture gradient profiles, and the RFT (actual fluid pressure data measured from repeated formation tests) and LOT data (leak off test data conducted at various casing shoe depths at nearby wells in the field) already available. The agreement from CWT predicted pore pressure and RFT data are excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com