Coaxial multiplex position detector and rotating machine using coaxial multiplex position detector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

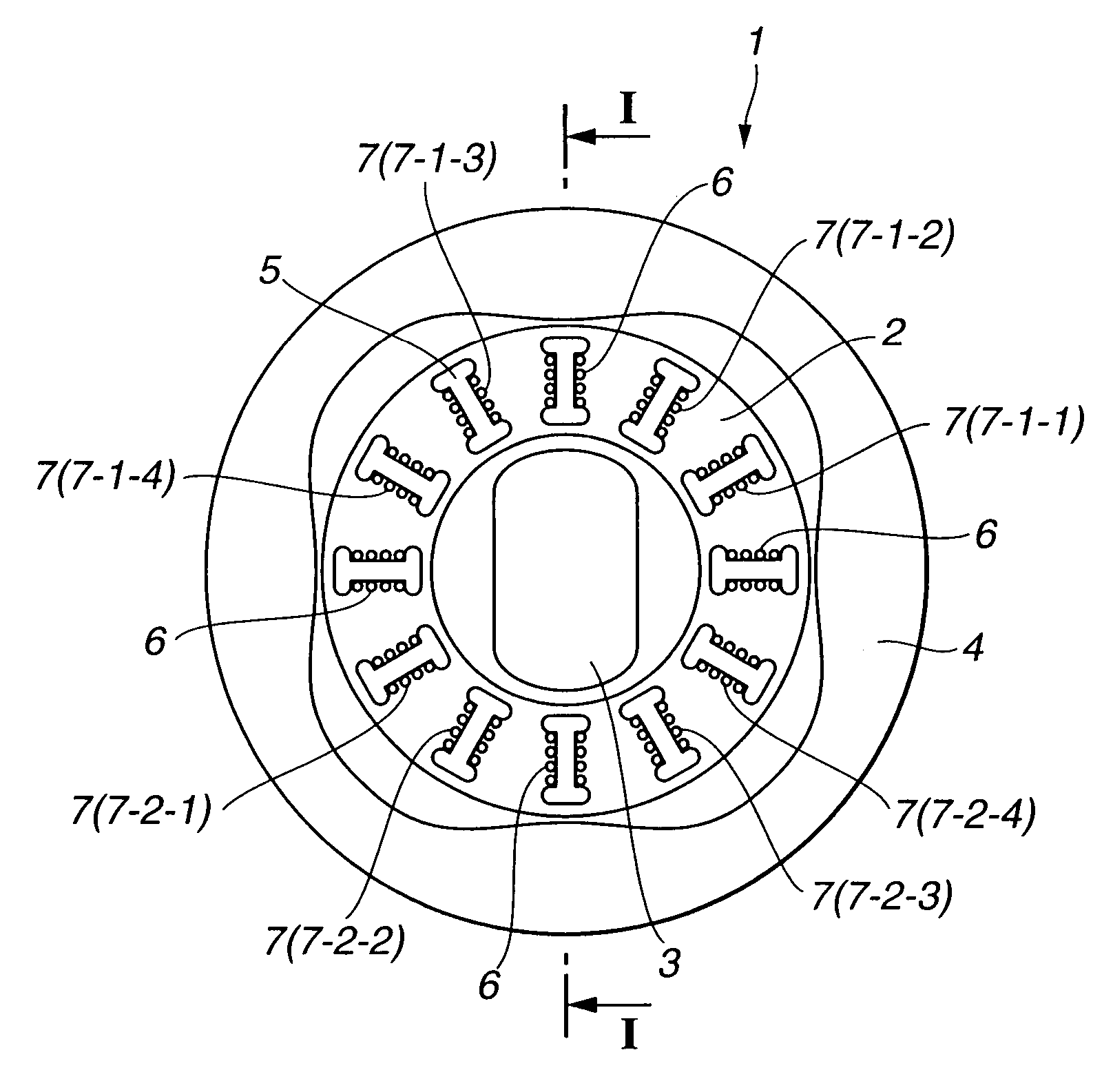

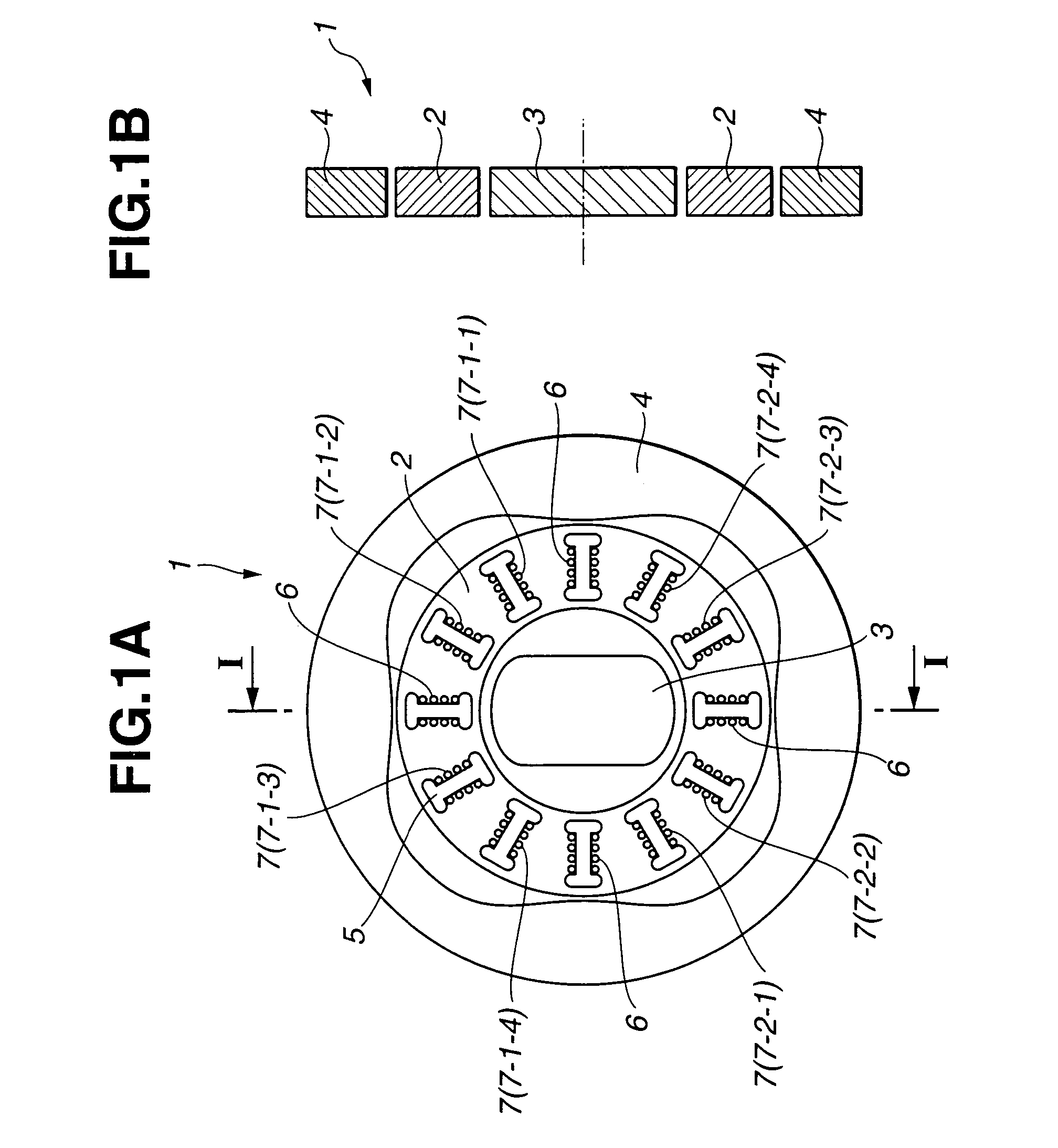

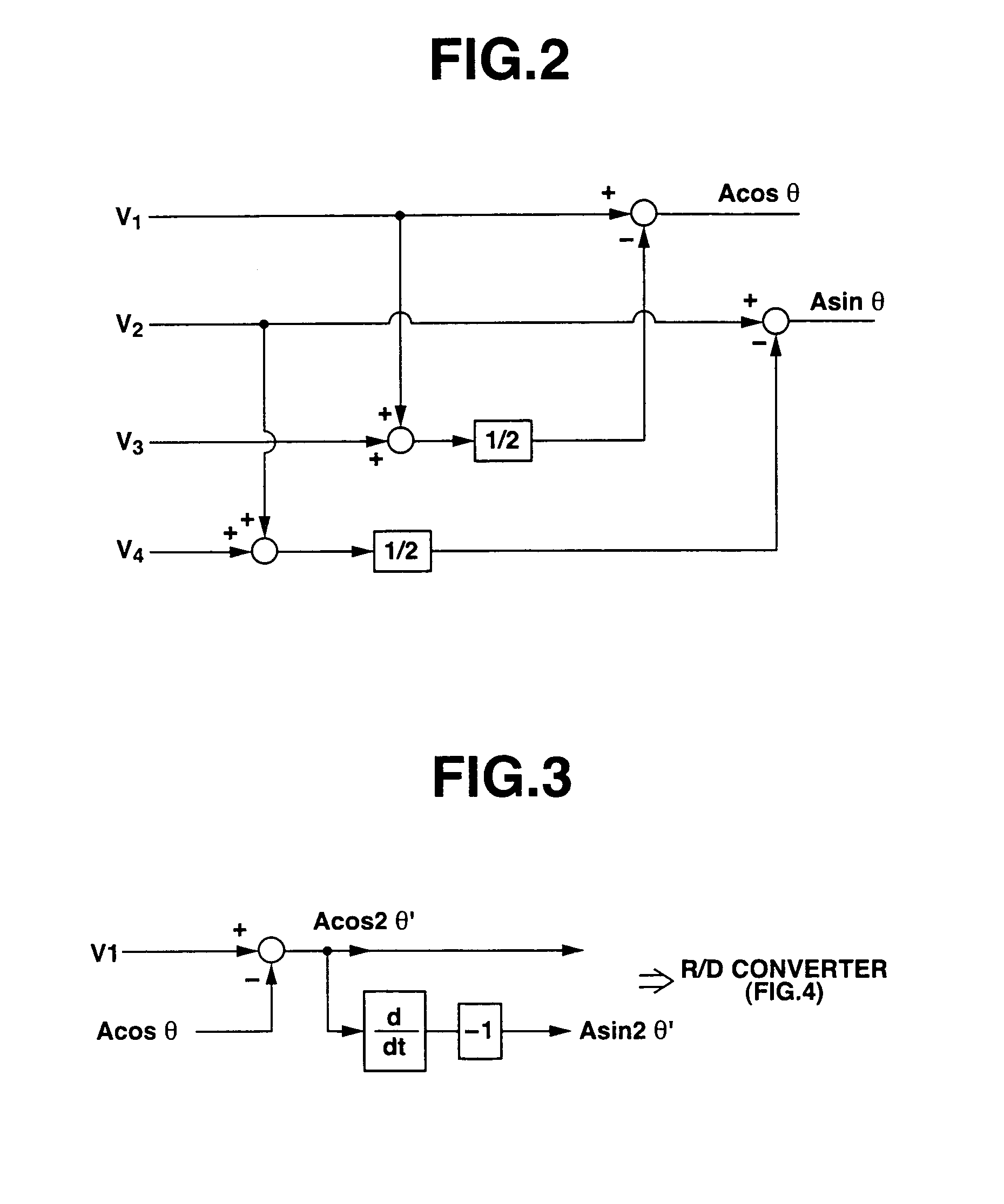

[0017]Reference will hereinafter be made to the drawings in order to facilitate a better understanding of the present invention.

[0018]Before explaining a preferred embodiment of the coaxial multiplex position detector according to the present invention, action and advantages of the present invention will be described below.

[0019]In the multiplex position detector according to the present invention, two rotor position detectors are reduced and changed to one position detector since the one position detector can detect two positions of rotors as will be described later. Hence, in a case where the detector is installed in the rotating machine, an axial length of the whole rotating machine can be shortened. Furthermore, the wiring around the two position detectors are reduced to one group only so that a probability of a dangerous accident such as a wiring breakage is reduced. In the multiple position detector according to the present invention, the inner and outer rotor are constituted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com