Component for motor vehicles with airbag cover

a technology for motor vehicles and components, applied in vehicle safety arrangements, pedestrian/occupant safety arrangements, transportation and packaging, etc., can solve the problems that the damage of passengers cannot be completely prevented, and the deployment of airbags can be damaged in the area of the wing edges, so as to achieve the thinest possible form stability and the effect of stabilizing the layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

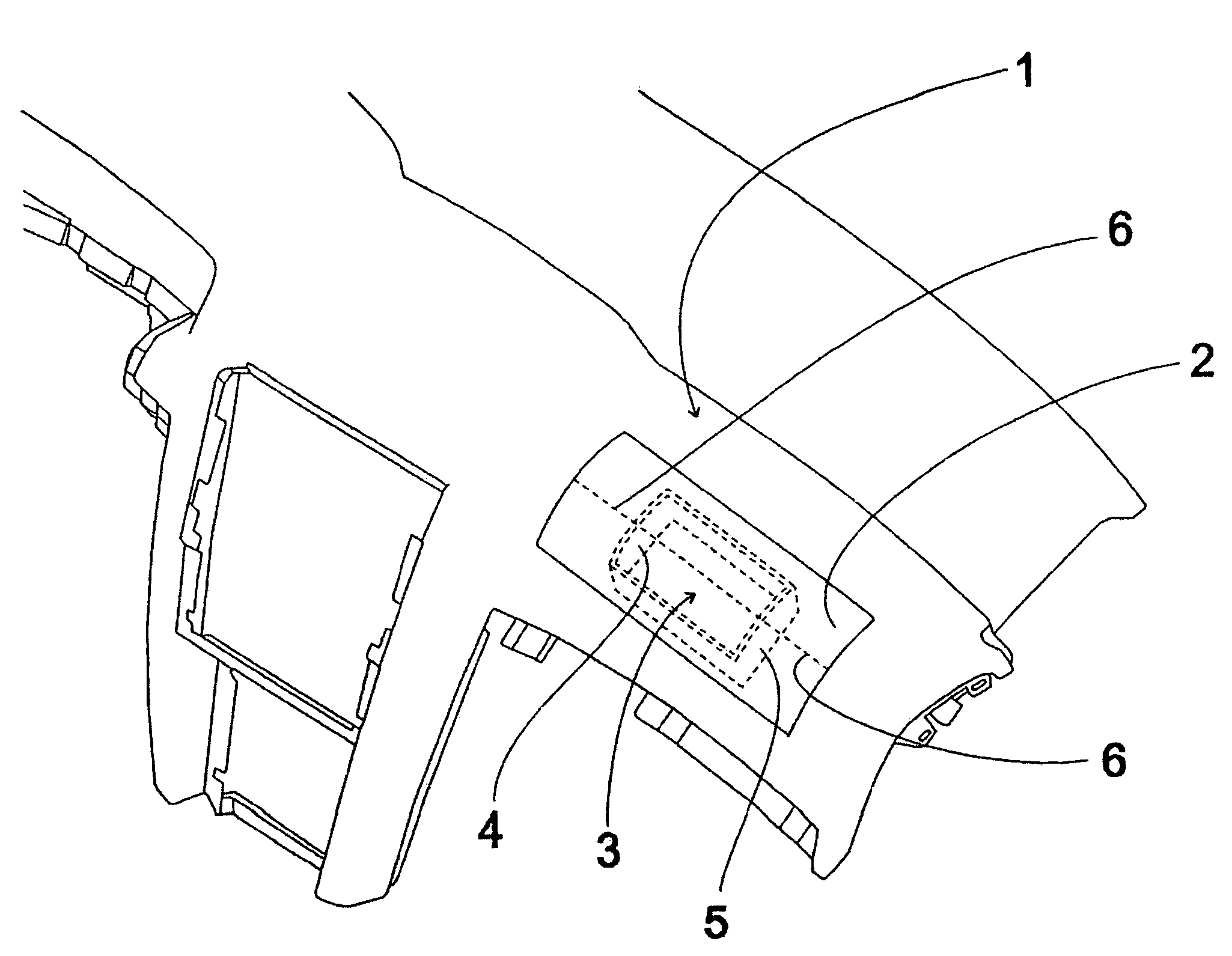

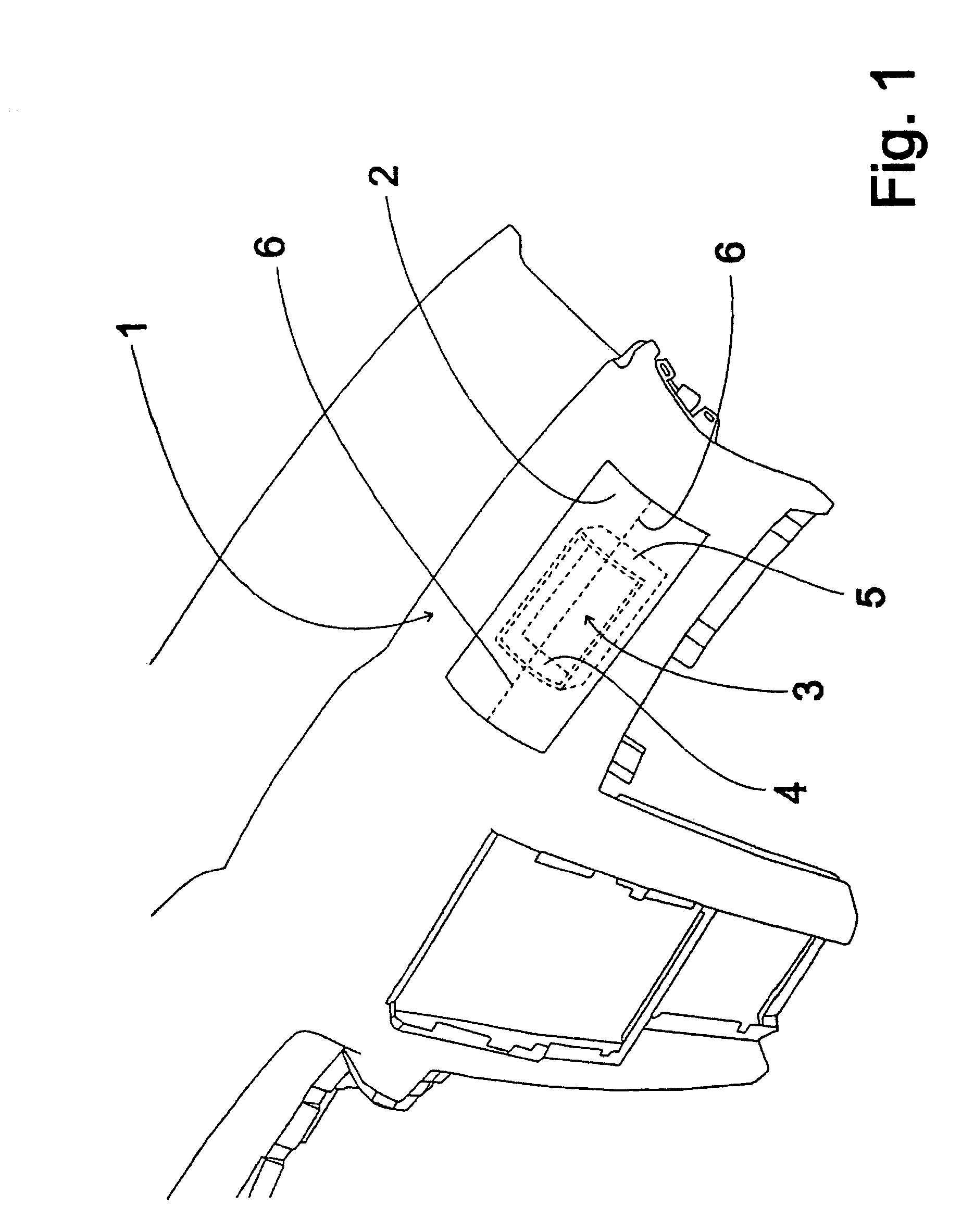

[0023]FIG. 1 shows a perspective view of an instrument panel 1 as an embodiment of the component for motor vehicles according to the present invention. The instrument panel 1, which can also be produced from a hard plastic material, shows an airbag cover 2 of elastic plastic material. The airbag cover 2 is disposed in the area of the deployment channel 3, which serves as a receptacle of an airbag not shown in FIG. 1. The airbag cover 2 covers the deployment channel 3 and exhibits a single weakened zone 6 extending preferably centrically between opposite walls 4, 5, which delimit the deployment channel 3, and extending relatively far, for example about one half of each the distance of the walls 4, 5, beyond each of the walls 4, 5 that serve as a delimitation of the deployment channel. The weakened zone 6 is formed, for example, by providing a slot or a recess in the surface of the instrument panel 1 facing away from the interior of the vehicle.

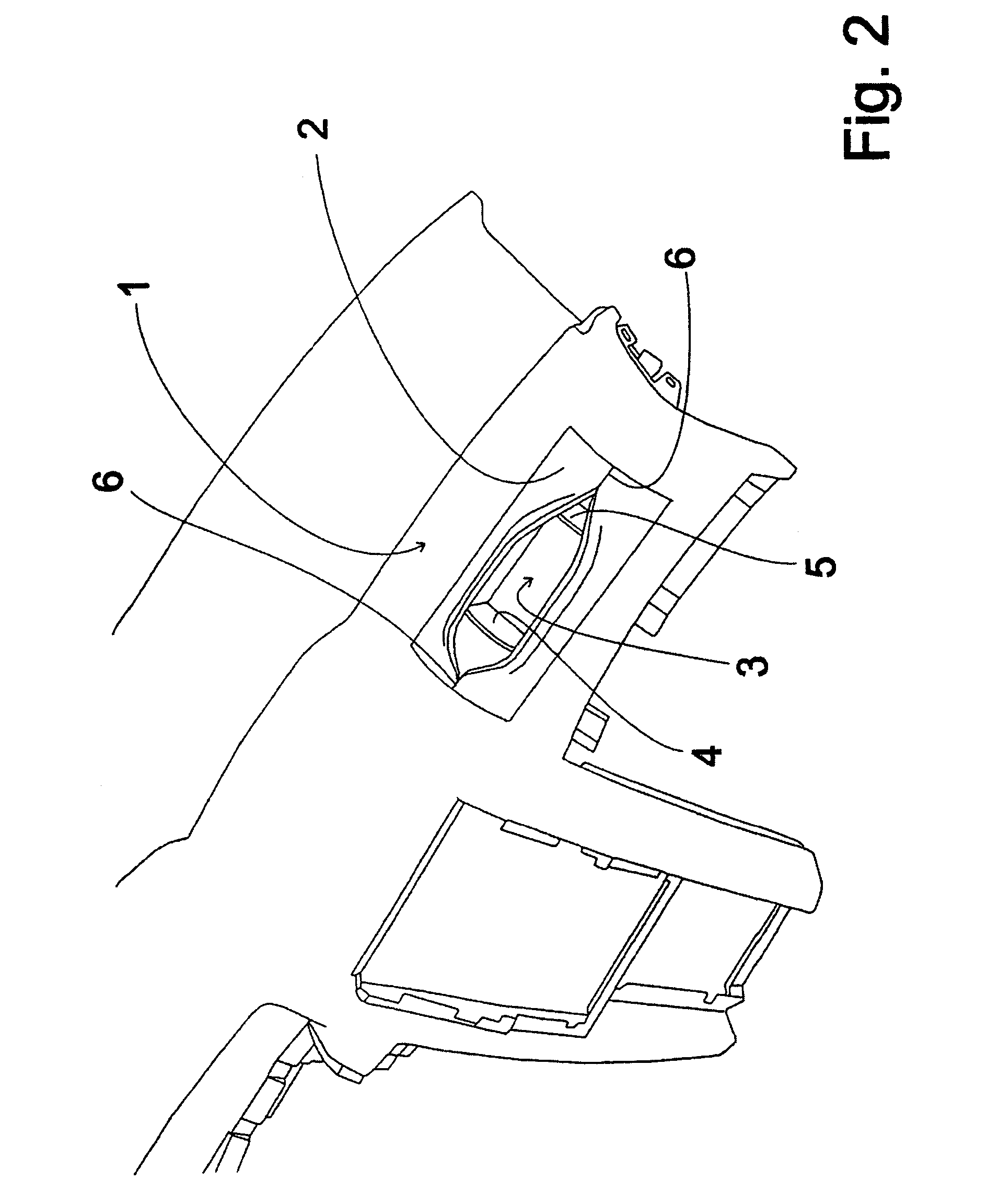

[0024]FIG. 2 shows a perspective view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com