Ozone-based conveyor cleaning system

a conveyor belt and cleaning technology, applied in the field of conveyor belt cleaning systems, can solve the problems of degrading the aesthetic appearance of the plant, affecting the cleaning effect of the plant, and affecting the cleanliness of the plant, and plant operators risk being reprimanded, fined, or shut down by the on-site usda inspector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

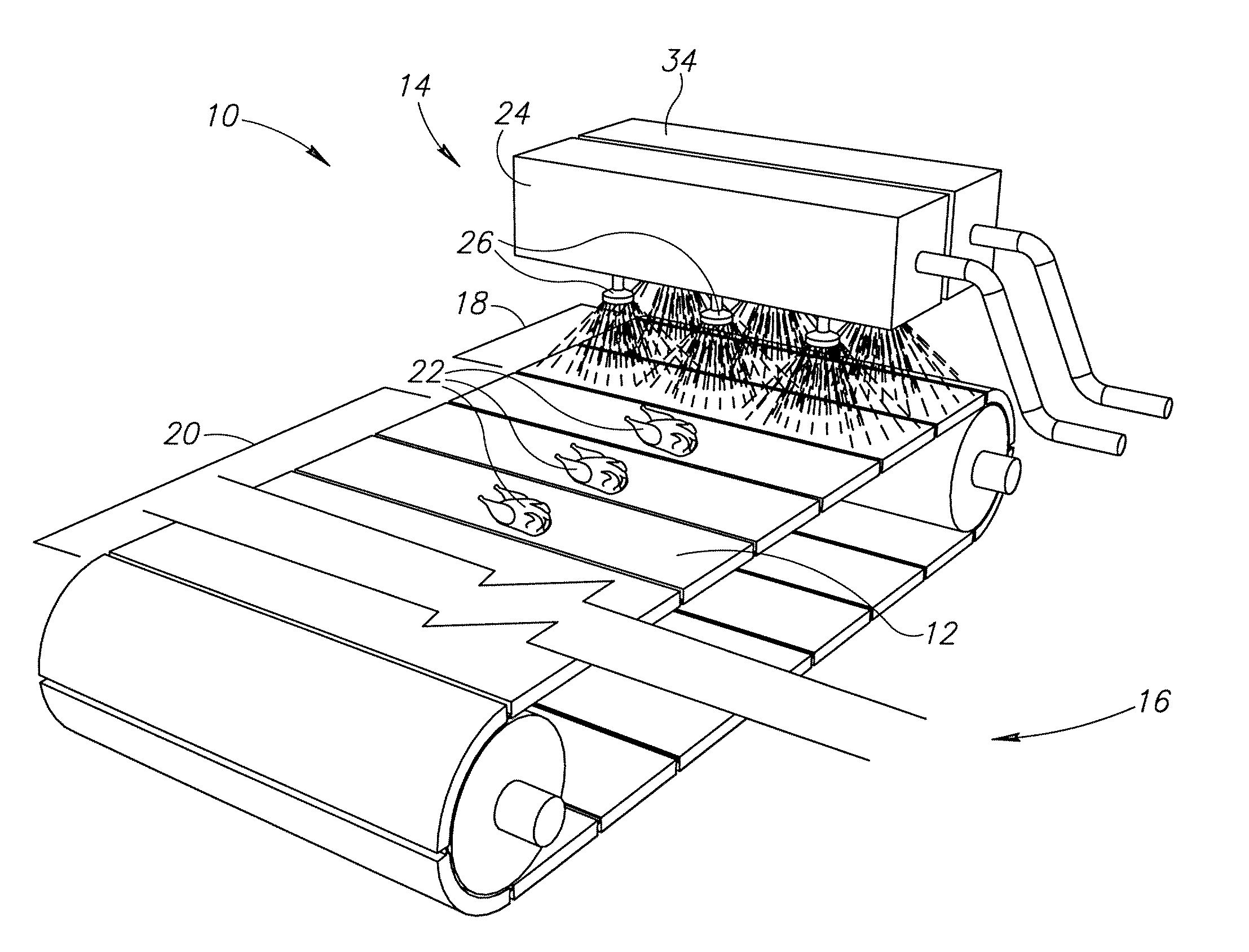

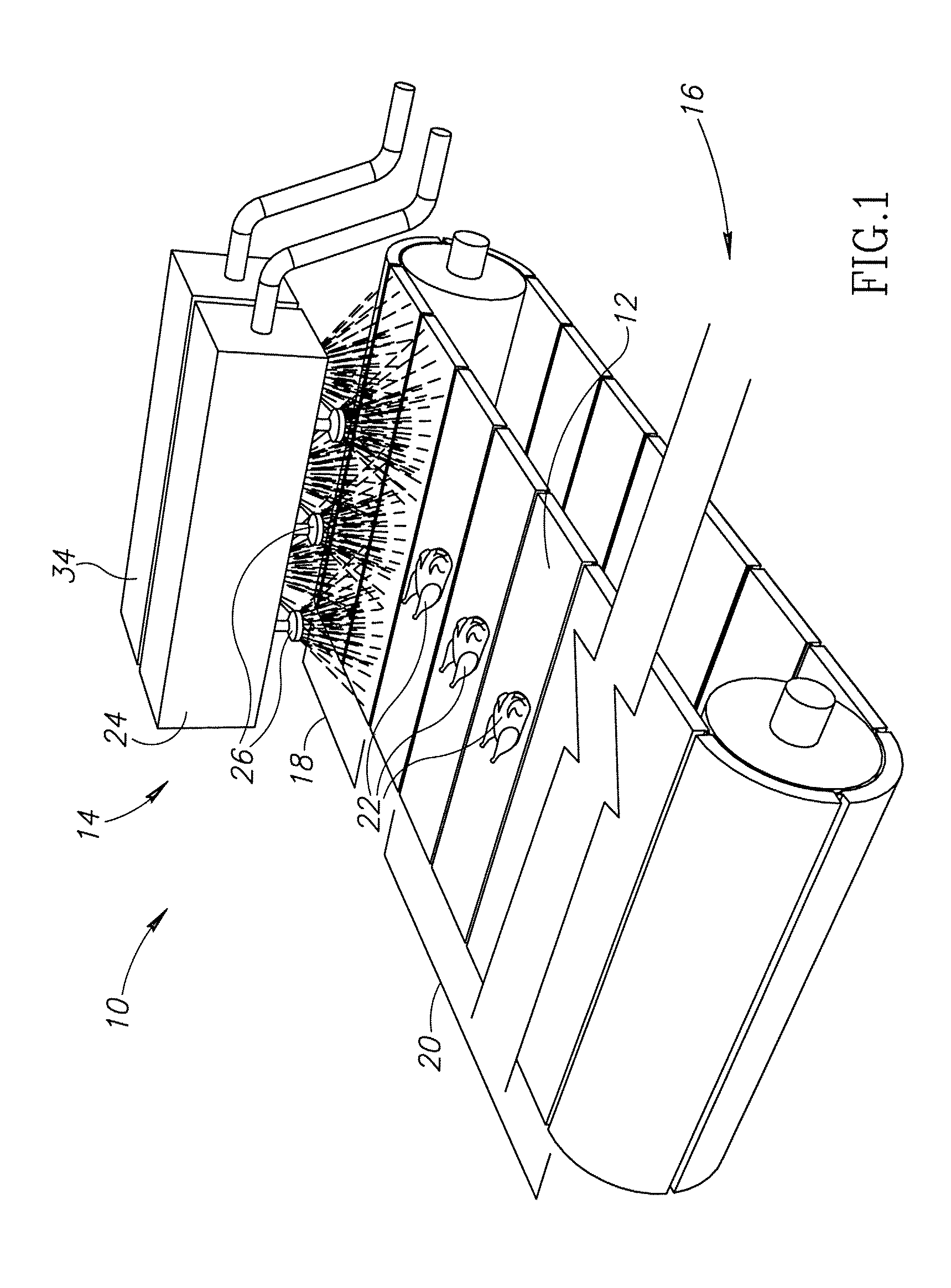

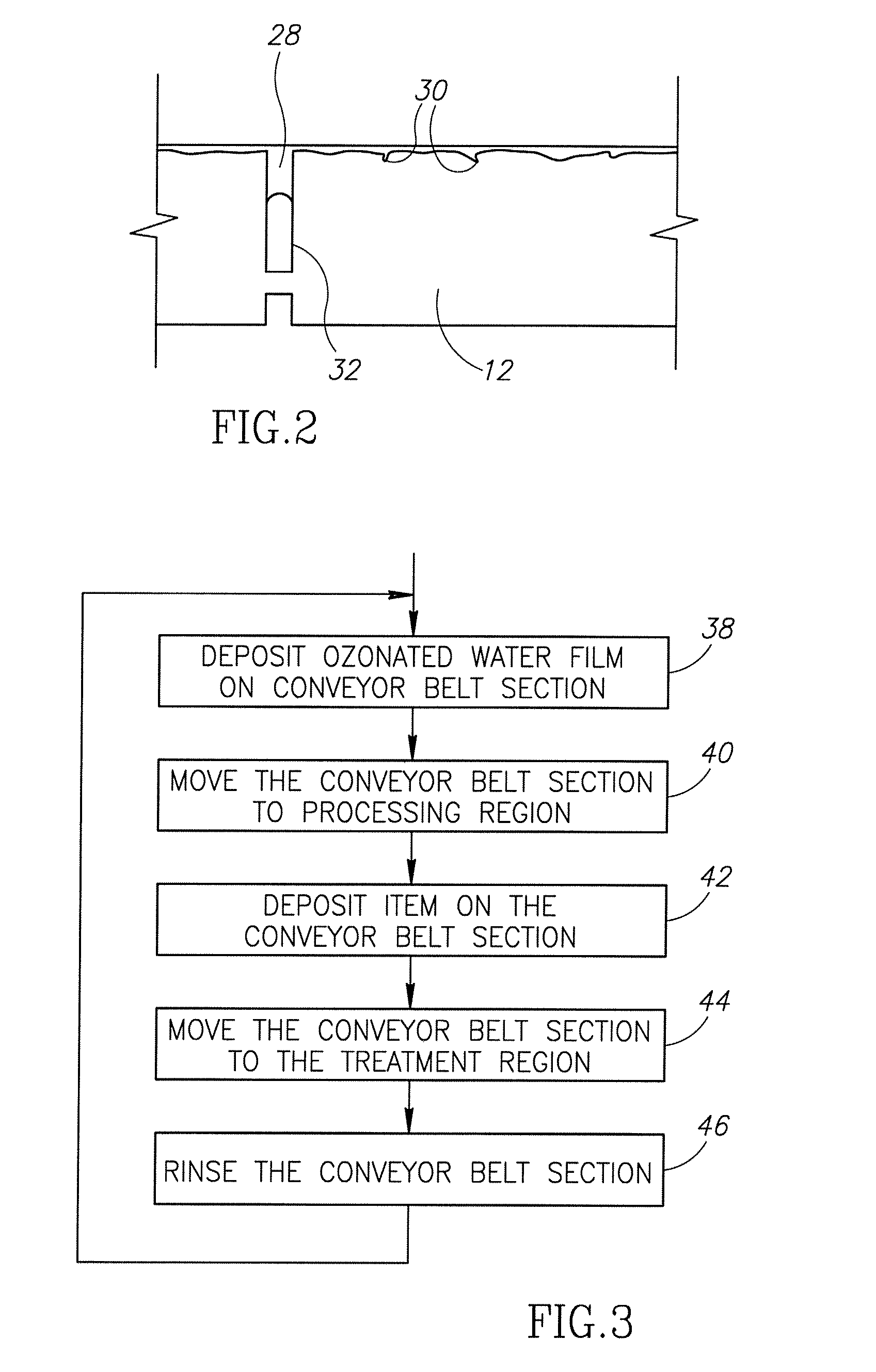

[0014]Referring to FIG. 1, a conveyor treating system 10 includes a conveyor belt 12 and a distributor 14. The conveyor belt 12 travels in direction 16 from a treating region 18 to a processing region 20. A distributor 14 located proximate the treating region 18 deposits a layer of ozonated water on the conveyor belt 12. In the processing region 20, animal carcasses 22 such as poultry as shown, and other meat products are deposited on the conveyor belt 12.

[0015]The distributor 14 may be embodied as a sprayer 24 having multiple heads 26 for spraying ozonated water across substantially the entire width of the conveyor belt 12. In the illustrated embodiment, the sprayer 24 includes heads 26 emitting a jet of water from 10 to 110 degrees wide at a rate of from 0.25 to 5 gallons per minute (gpm). The spray patterns of the heads 26 may overlap to ensure complete coverage. The heads 26 are typically located from 2 to 12 inches from the surface of the conveyor belt 12.

[0016]The ozonated wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com