Exhaust-gas turbocharger for an internal combustion engine

a technology of exhaust gas and turbocharger, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of more expensive die parts, and achieve the effects of compact overall design, reduced mechanical and thermal requirements of precision casting guide vane grids, and increased flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

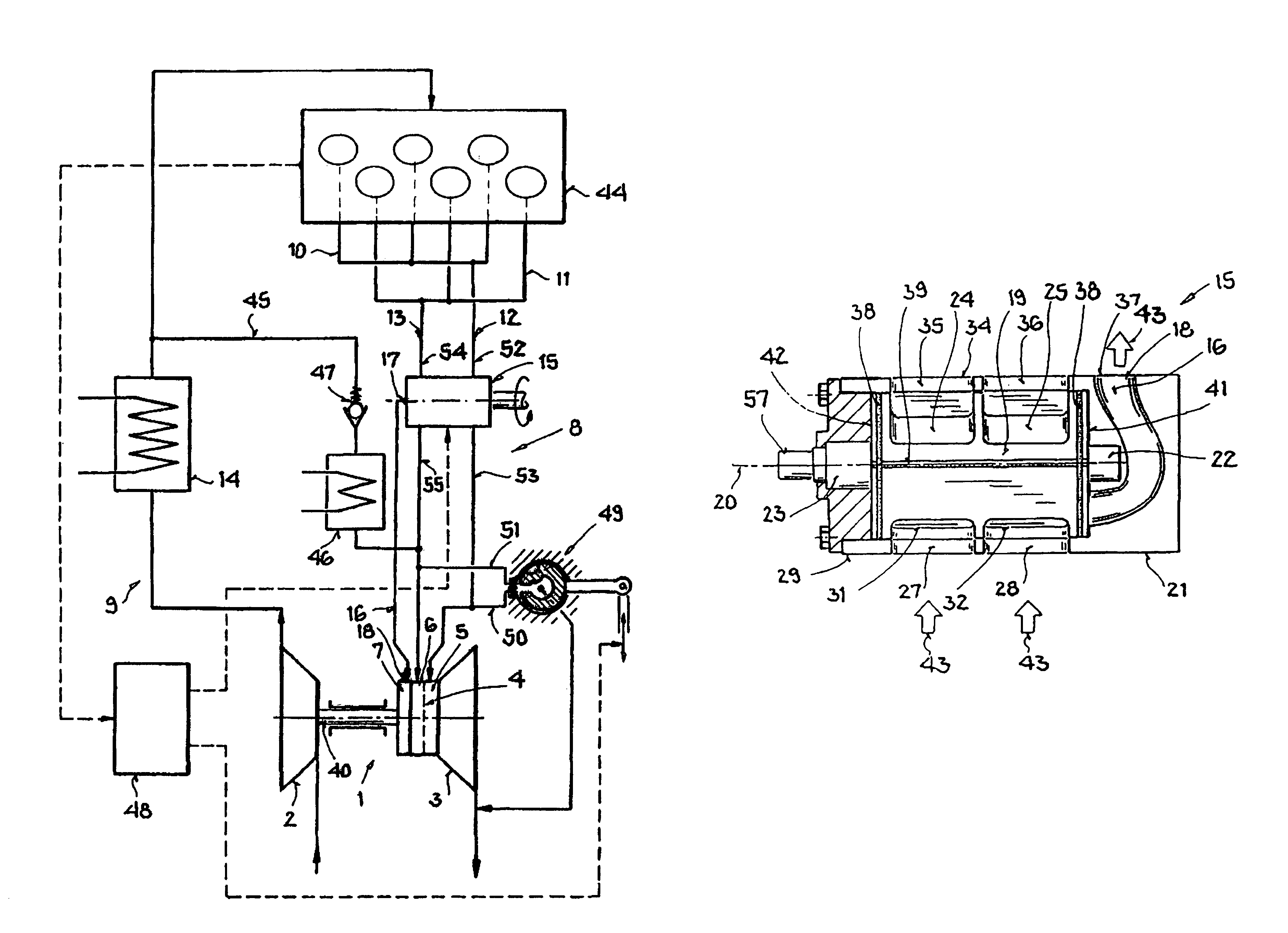

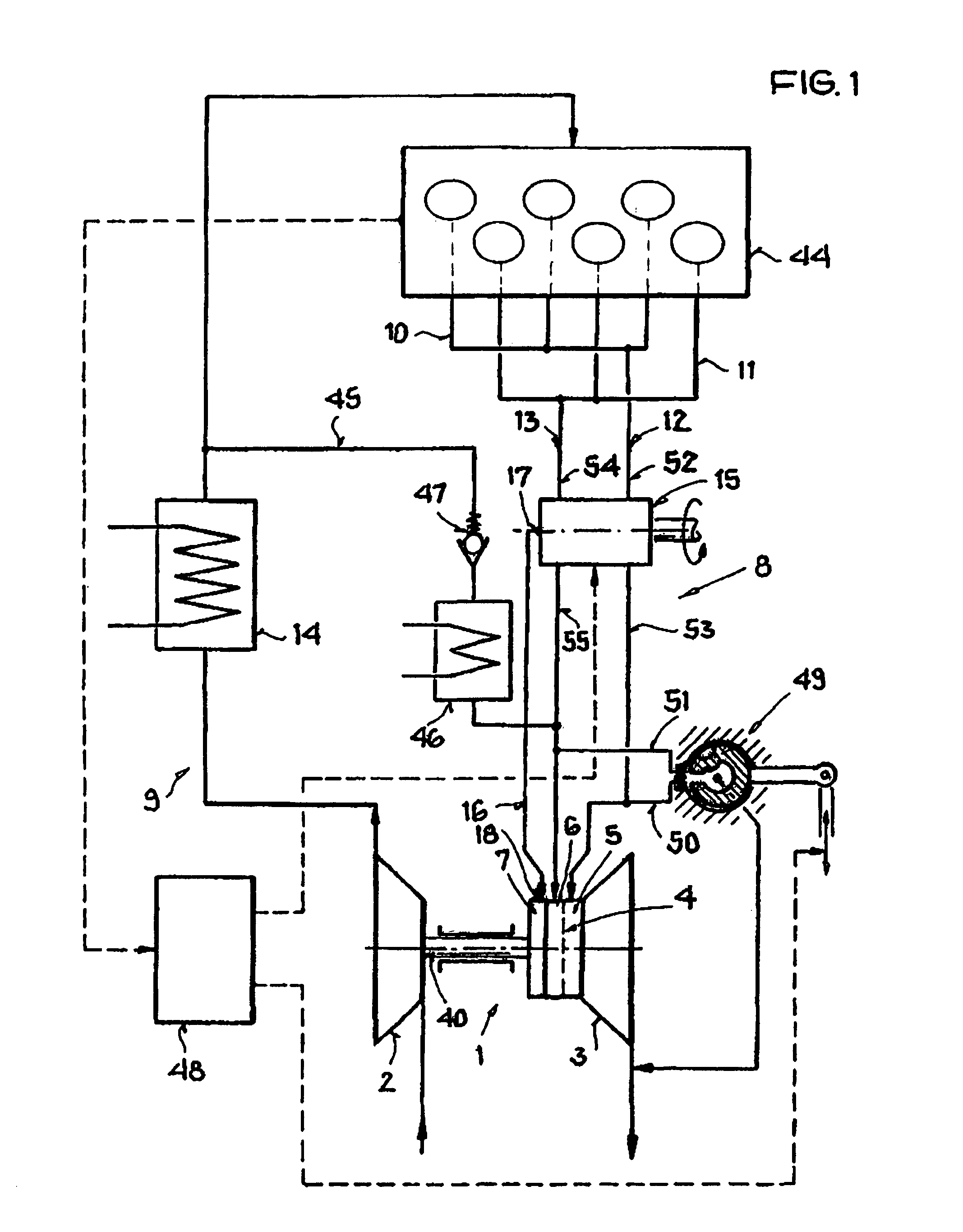

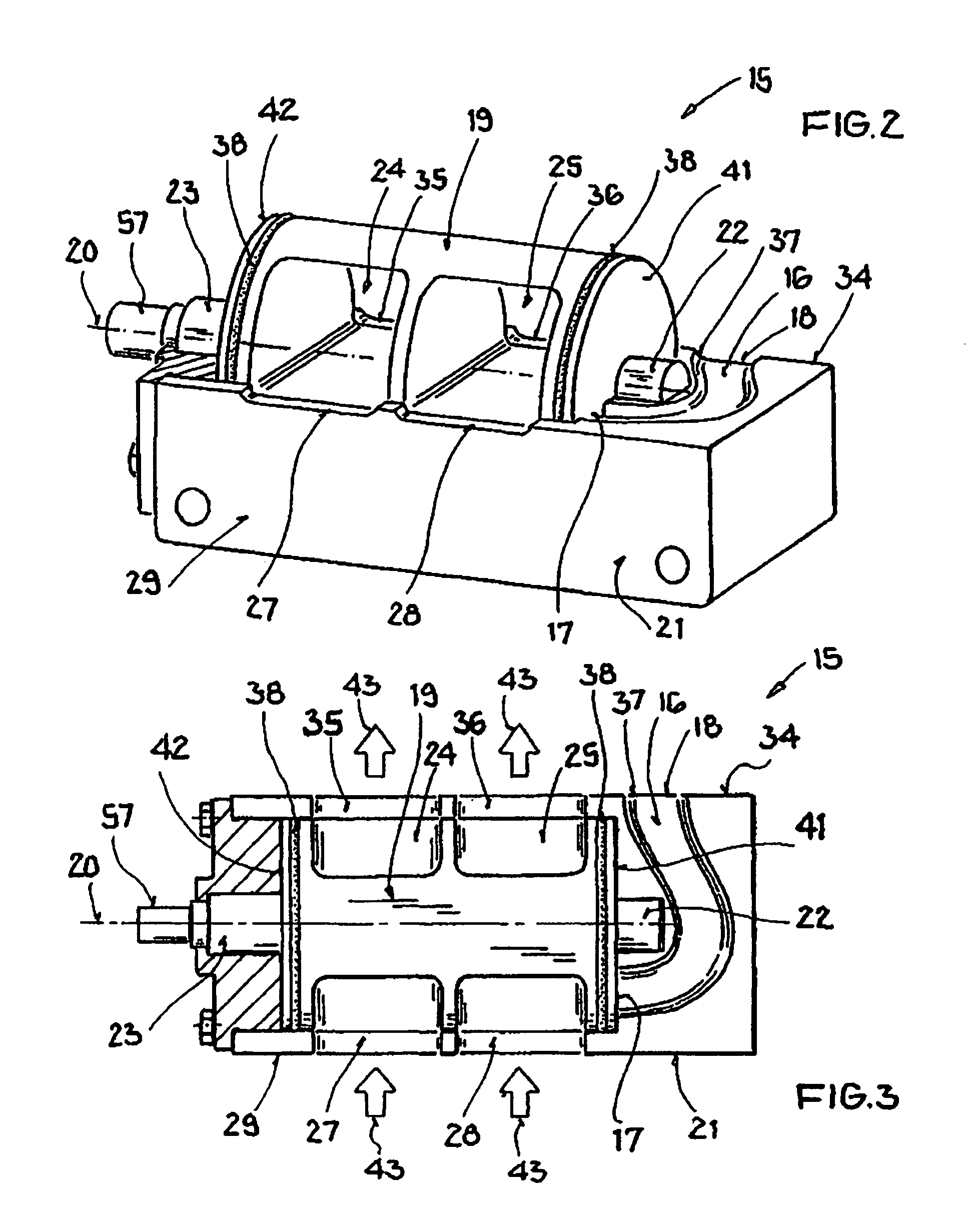

[0022]In the figures, identical or identically acting components are provided with identical designations.

[0023]FIG. 1 shows an internal combustion engine 44, a diesel engine or a spark ignition engine, for a motor vehicle, which internal combustion engine 44 has an exhaust gas section 8 and an intake section 9. The internal combustion engine 44 includes an exhaust-gas turbocharger 1. The exhaust-gas turbocharger 1 comprises a compressor 2 which is connected fixedly in terms of rotation to a turbine 3 via a shaft 40. The turbine 3 is driven by the exhaust gas of the internal combustion engine 44 and drives the compressor 2 via the shaft 40 with the result that combustion air can be sucked in and compressed by the compressor 2. The turbine 3 has a turbine wheel 4 and three flow passages, a first flow passage 5, a second flow passage 6 and a third flow passage 7. A charge air cooler 14 for cooling the compressed combustion air is accommodated in the intake section 9 of the internal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com