Two-step roller finger cam follower assembly having a follower travel limiter

a follower assembly and roller finger technology, applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of engine noise and error, hla will not recover, and engulf air, and achieve the effect of preventing excessive leakage of the associated hydraulic lash adjuster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

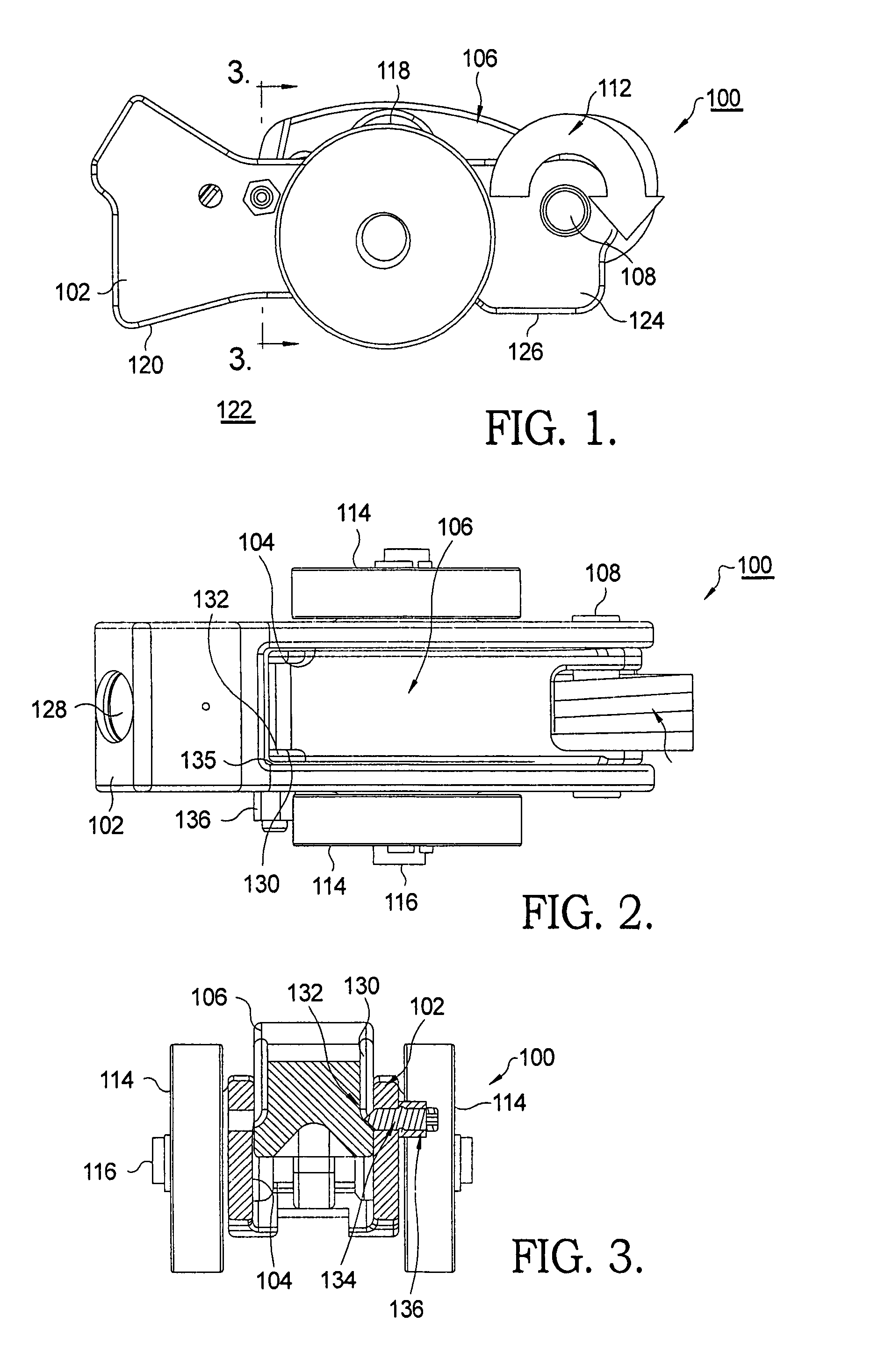

[0016]In accordance with the invention and a first embodiment thereof, high lift follower 106 is provided with a relief 130 along one or both sides thereof, creating a land 132 that preferably is sloped with respect to the direction of travel of follower 106. A limiting stop 134 comprising a screw is threadedly received in a threaded bore in body 102 and extends into central aperture 104 and relief 130 so as to engage land 132 at a predetermined limit of rotational travel of follower 106 in direction 112 with respect to body 102. Preferably, limiting stop screw 134 is tapered at the inner end thereof 135 to permit adjustment of the engagement point with land 132 and thus adjustment of the limit of rotational travel of follower 106. A lock nut 136 may be provided to secure screw 134 in a set position as desired.

[0017]Referring now to FIGS. 4-6, a second two-step roller finger follower assembly 200 illustrates additional embodiments of a limiting stop in accordance with the invention....

embodiment 100

[0018]Assembly 200 is mechanically essentially identical with assembly 100 except that a compression spring 210 in a well 211 formed in high-lift follower 206 replaces torsion spring 110 in embodiment 100. Also note that a latching mechanism 213 of a similar type that would be used in assembly 100, and HLA head 215 are shown.

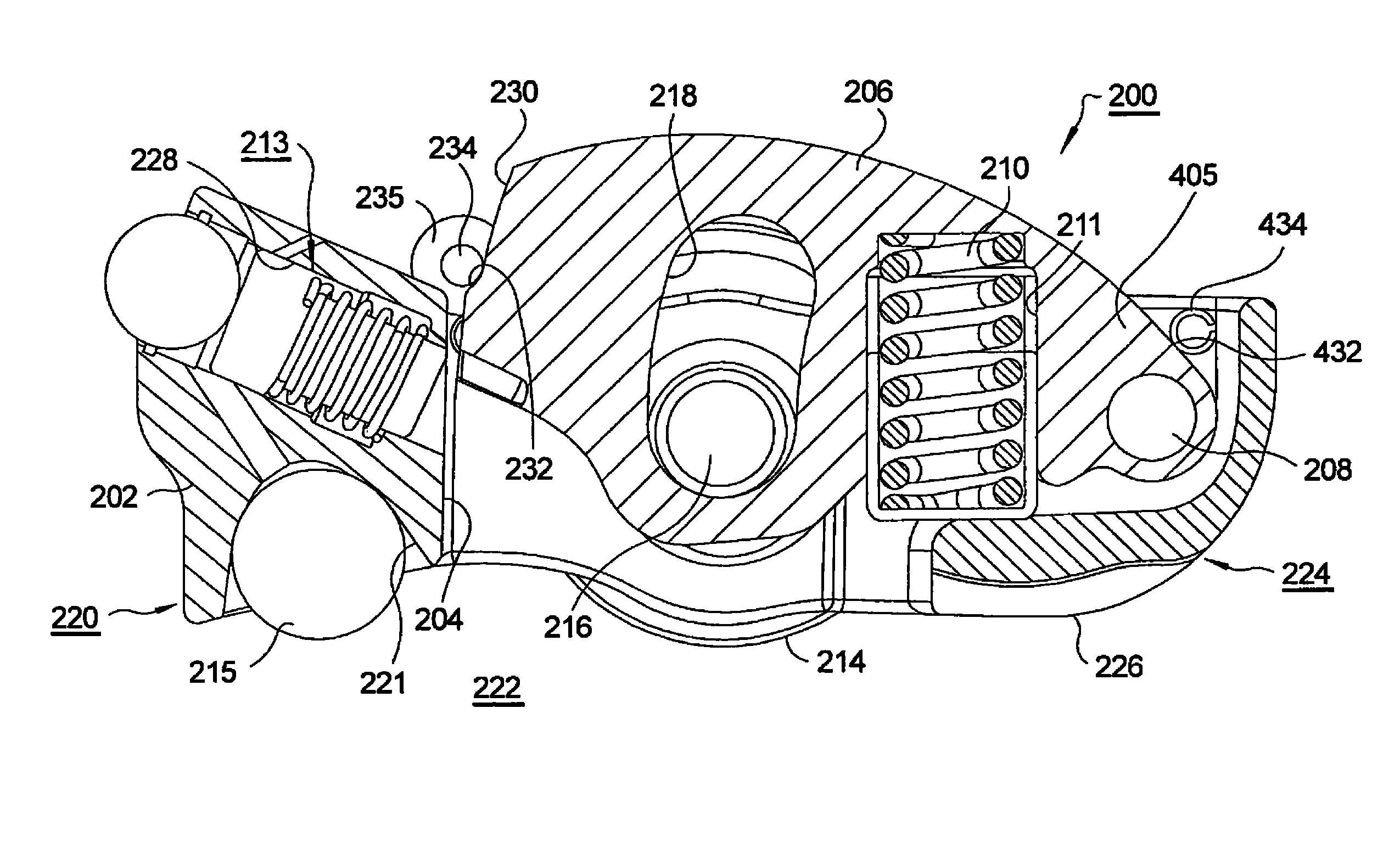

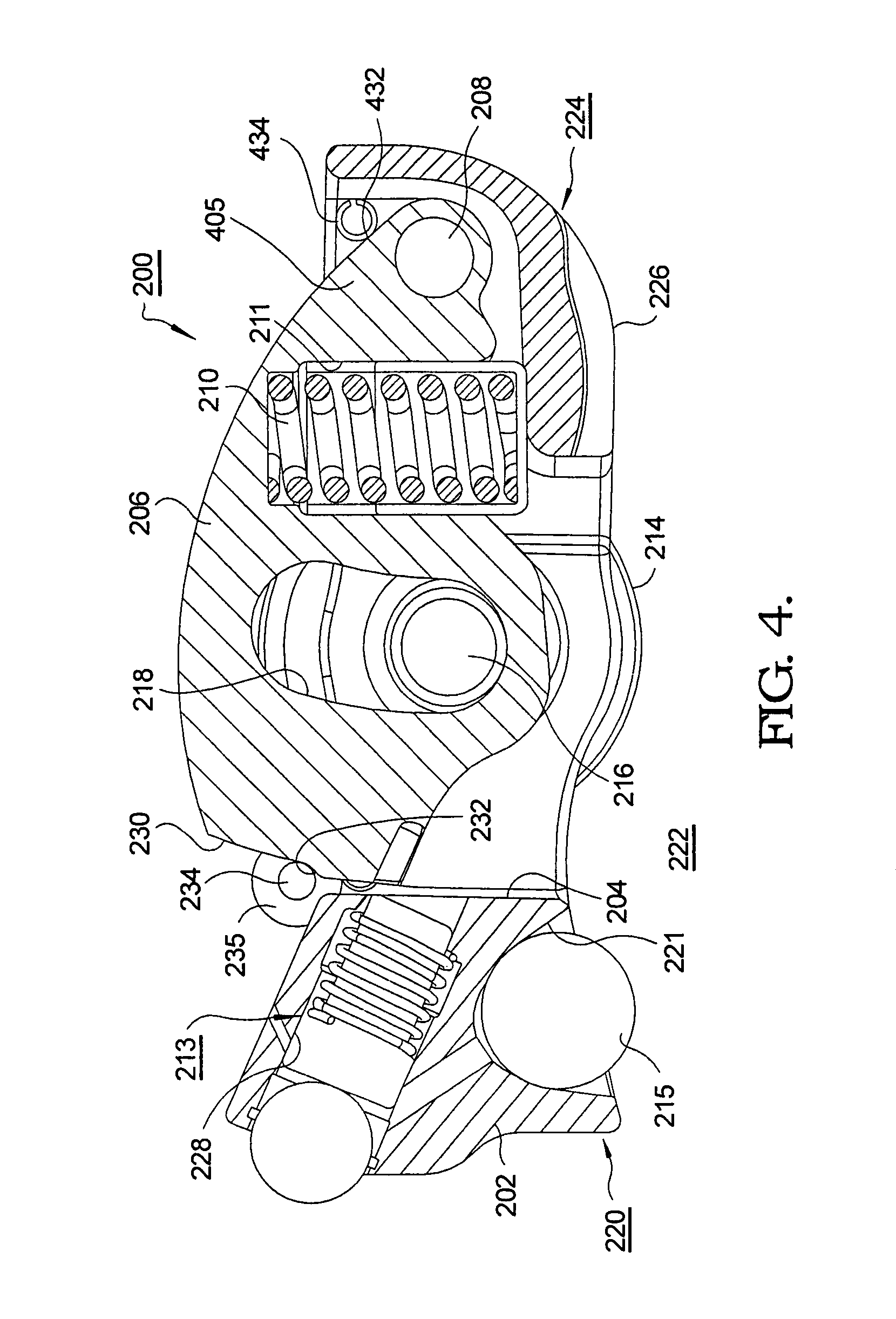

[0019]Assembly 200 comprises a follower body 202 having a central aperture 204 for receiving a high-lift follower 206 that is pivotably secured to body 202 via a pin 208. A roller 214 is mounted on an axle 216 that is mounted, preferably on needle bearings (not shown), in a bore through the sidewalls of body 202. Axle 216 passes through an arcuate slot 218 in high-lift follower 206, permitting the follower to rotate freely about pin 208. A first end 220 of body 202 includes a hemispherical socket 221 for pivotably receiving the spherical head 215 of a hydraulic lash adjuster upon which follower assembly 200 is mounted in an engine 222. A second end 224 of body 2...

second embodiment

[0020]In accordance with the invention and a second embodiment thereof, high lift follower 206 is provided with a relief 230 along the latching end thereof, creating a land 232. A limiting stop 234 comprising a roll pin is received in a boss 235 formed in body 202 and extends into relief 230 so as to engage land 232 at a predetermined limit of rotational travel of follower 206 with respect to body 202.

[0021]Referring now to FIG. 5, a third embodiment is similar to the just-described second embodiment except that relief 330 and land 332 are formed along the side 333 of follower 306. Boss 335 is placed accordingly such that limiting stop 334, such as a roll pin, extends into relief 330 and engages land 332, thereby limiting the rotation of follower 306 within body 302.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com