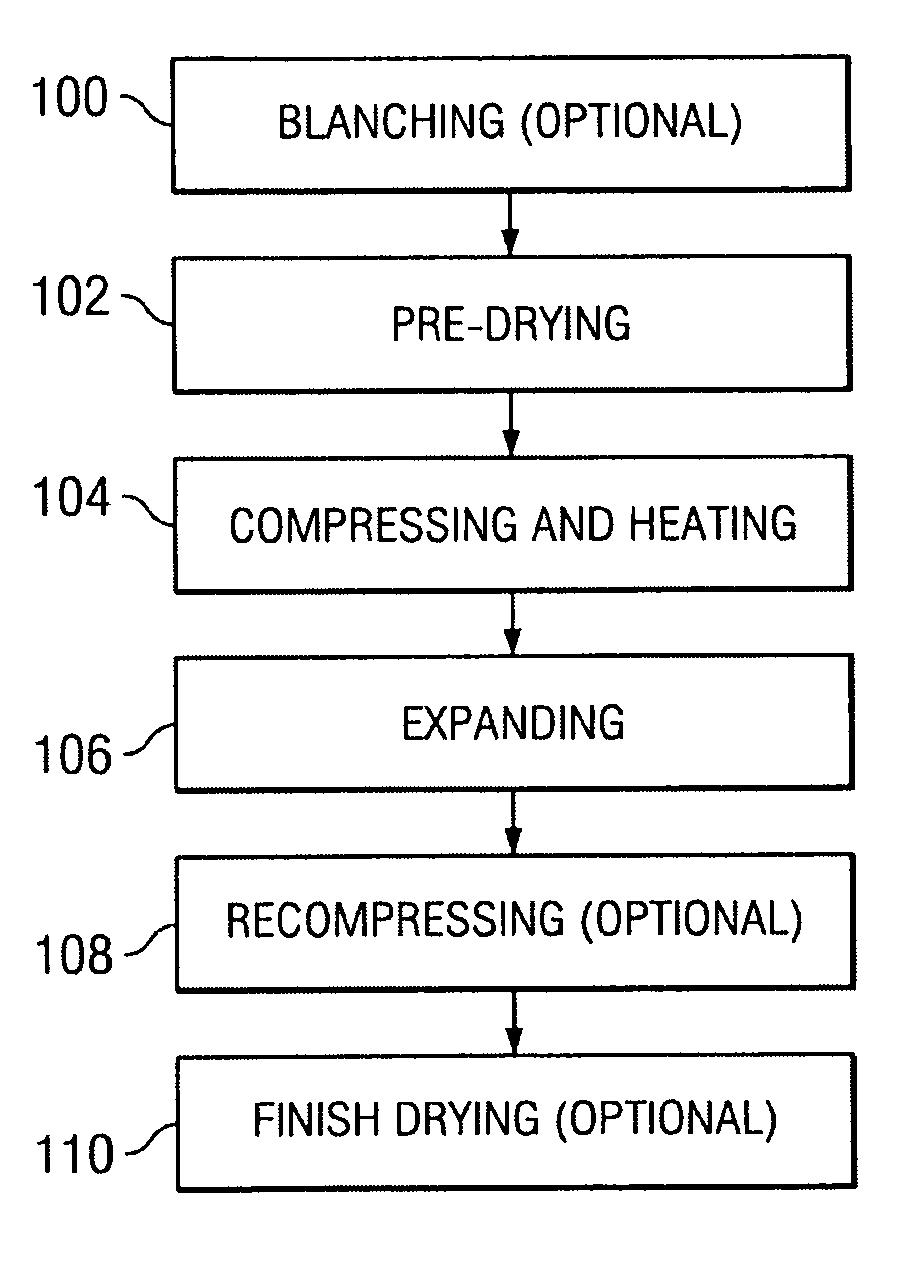

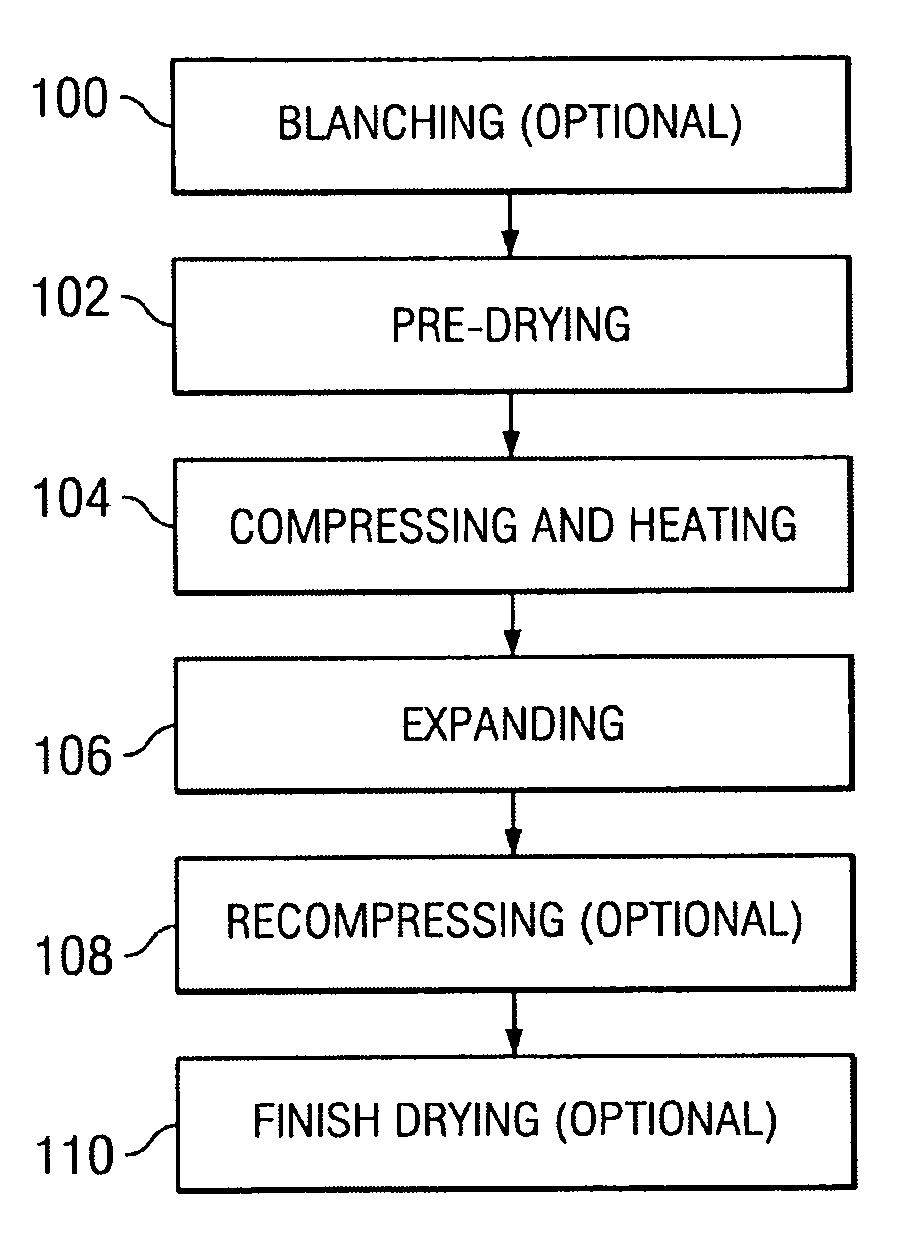

Process for producing baked potato slices with expanded texture

a technology of baked potato and texture, which is applied in the field of process for producing baked potato slices with expanded texture, can solve the problems of lack of light, crispy, expanded qualities of fried potato chips, and no prior art process has been successful in creating potatoes, etc., and achieves rapid dehydration and expansion, thin and crunchier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Baked Expanded Potato Chip

[0022]Raw potato slices between about 0.5 millimeters and about 3 millimeters thick were blanched in boiling water for between about 30 seconds and about 4 minutes. The potato slices were then pre-dried in an air stream and introduced into a microwave oven. The microwave oven contained superheated steam at a temperature between about 100° C. and about 160° C., which helped encourage even heating and prevent dehydration at higher temperatures (although the temperature of the potato slices was kept below 110° C.). The potato slices were heated in the microwave / steam oven for between about 30 seconds and about 10 minutes, until their moisture content was between about 11% and about 14% by weight.

[0023]Each slice was then heated and compressed in apressure popper. In the pressure popper, the bottom plate initially formed a cavity inside the mold. Each potato slice was then fed into the cavity and the top plate and bottom plate compressed and heated the potato s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com