Battery assembly and method of forming the same

a battery and assembly technology, applied in the field of rechargeable battery pack assembly, to achieve the effect of reducing weight, improving structural integrity of battery assembly, and efficient packaging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

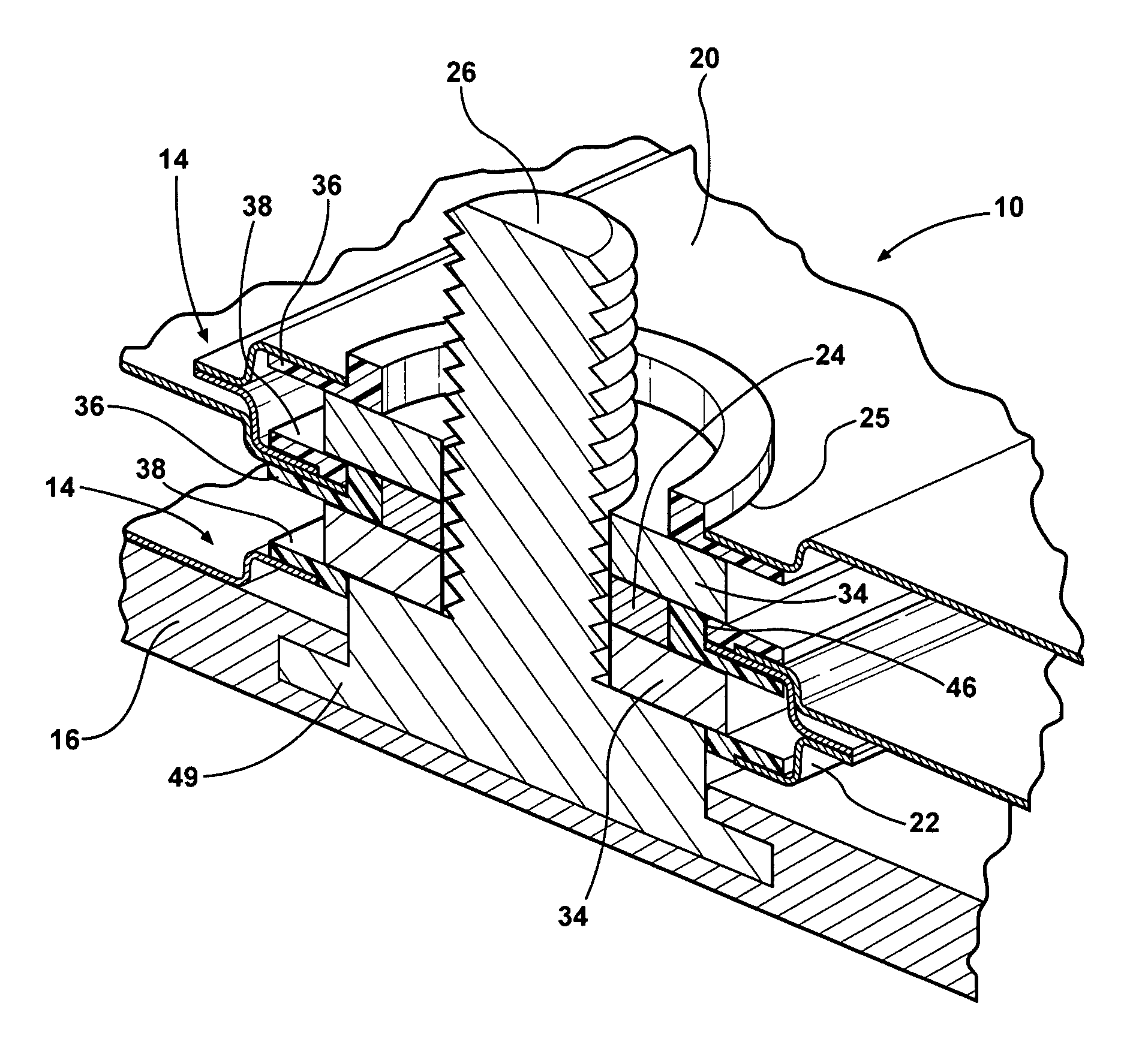

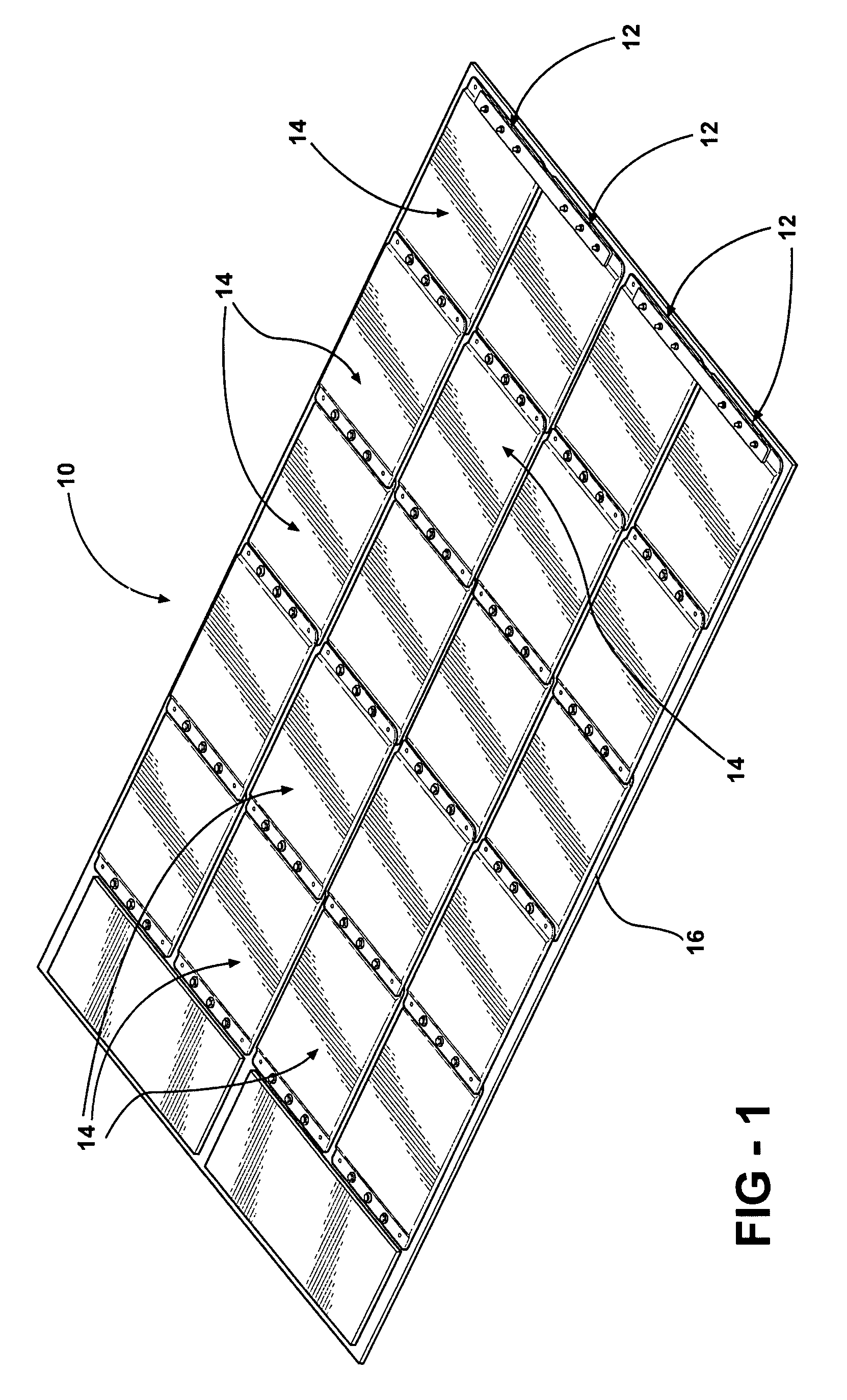

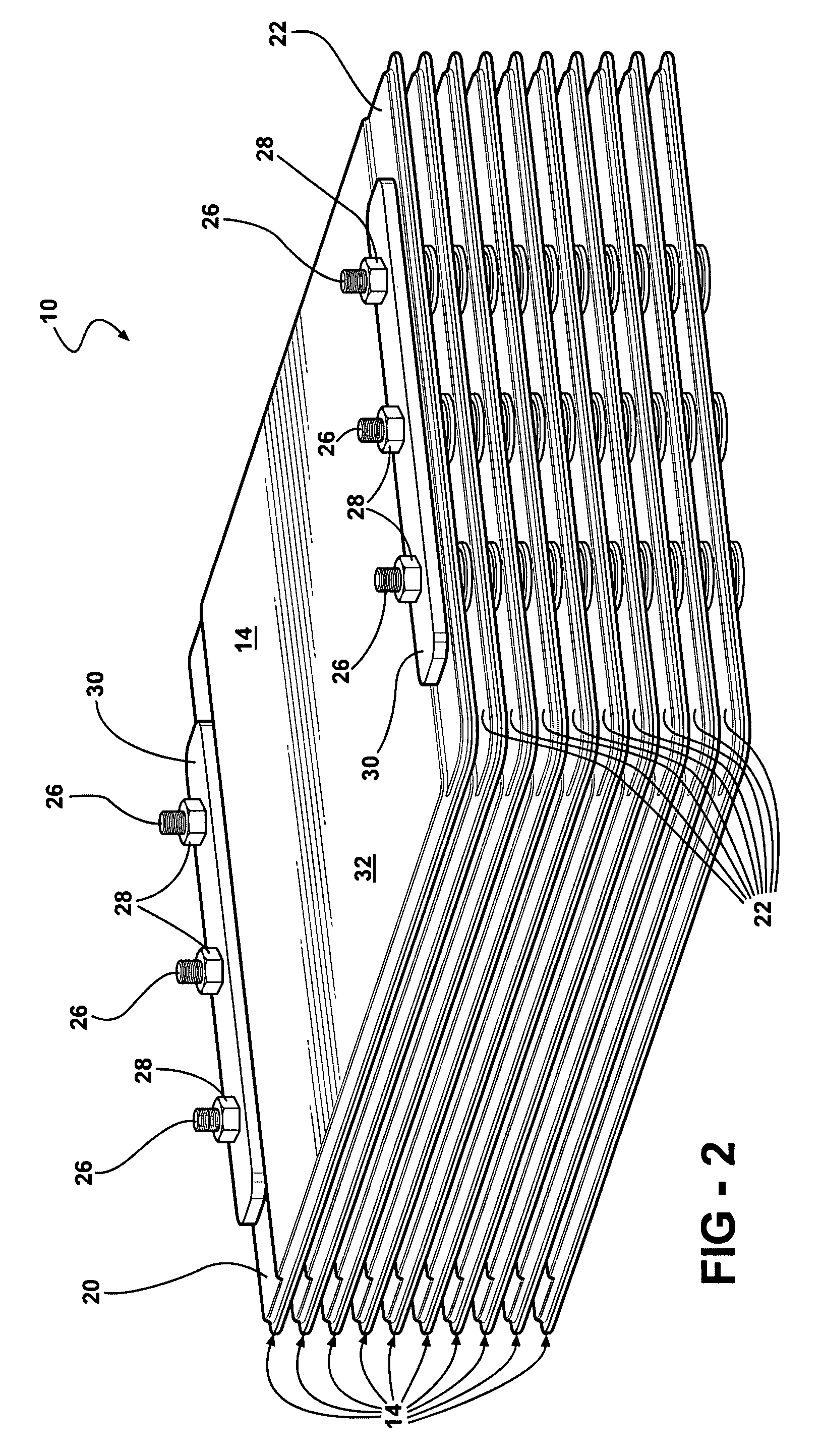

[0029]Referring to the Figures, wherein like numerals indicate like or corresponding parts, a battery assembly or a battery pack of the present invention is generally shown at 10. Preferably, the battery pack 10 includes four rows, generally indicated at 12, of battery cells (the cell), generally indicated at 14, connected with and extending along each row 12 in overlapping relationship. Each row 12 includes five stacks of the cells 14. Each stack of the cells 14 are interconnected with one another in the pattern known to those skilled in the battery art and extend along each row 12 in overlapping relationship with one another. The battery pack 10 is supported by and connected to a tray 16 formed from a polymeric material. A battery pack 10 of the present invention is adaptable to be utilized in various configurations including and not limited to an overlapping battery cell packaging configuration, as illustrated in FIGS. 1, 3, 4, and 6, a vertical stack battery cell packaging confi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| insulator | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com