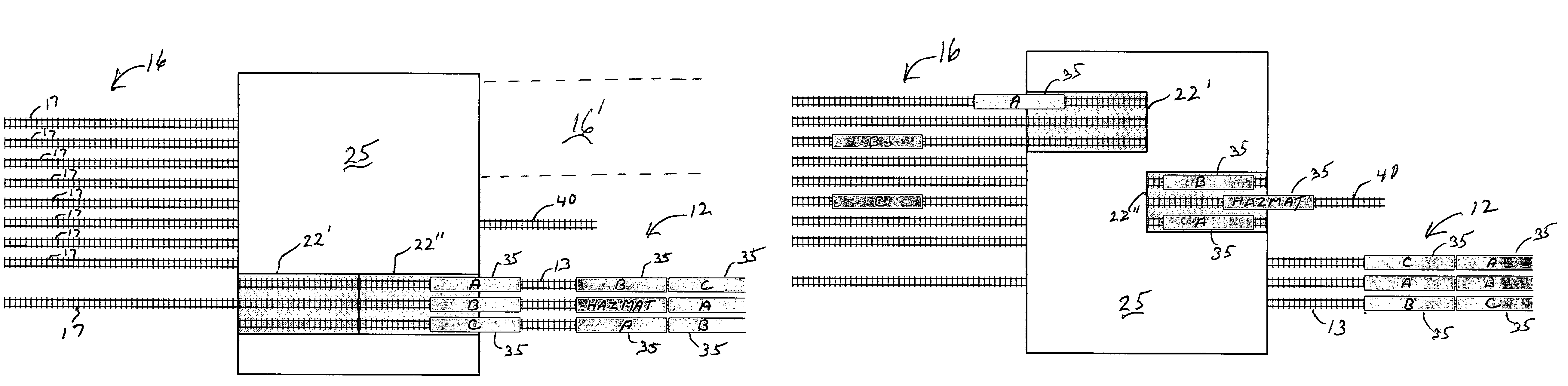

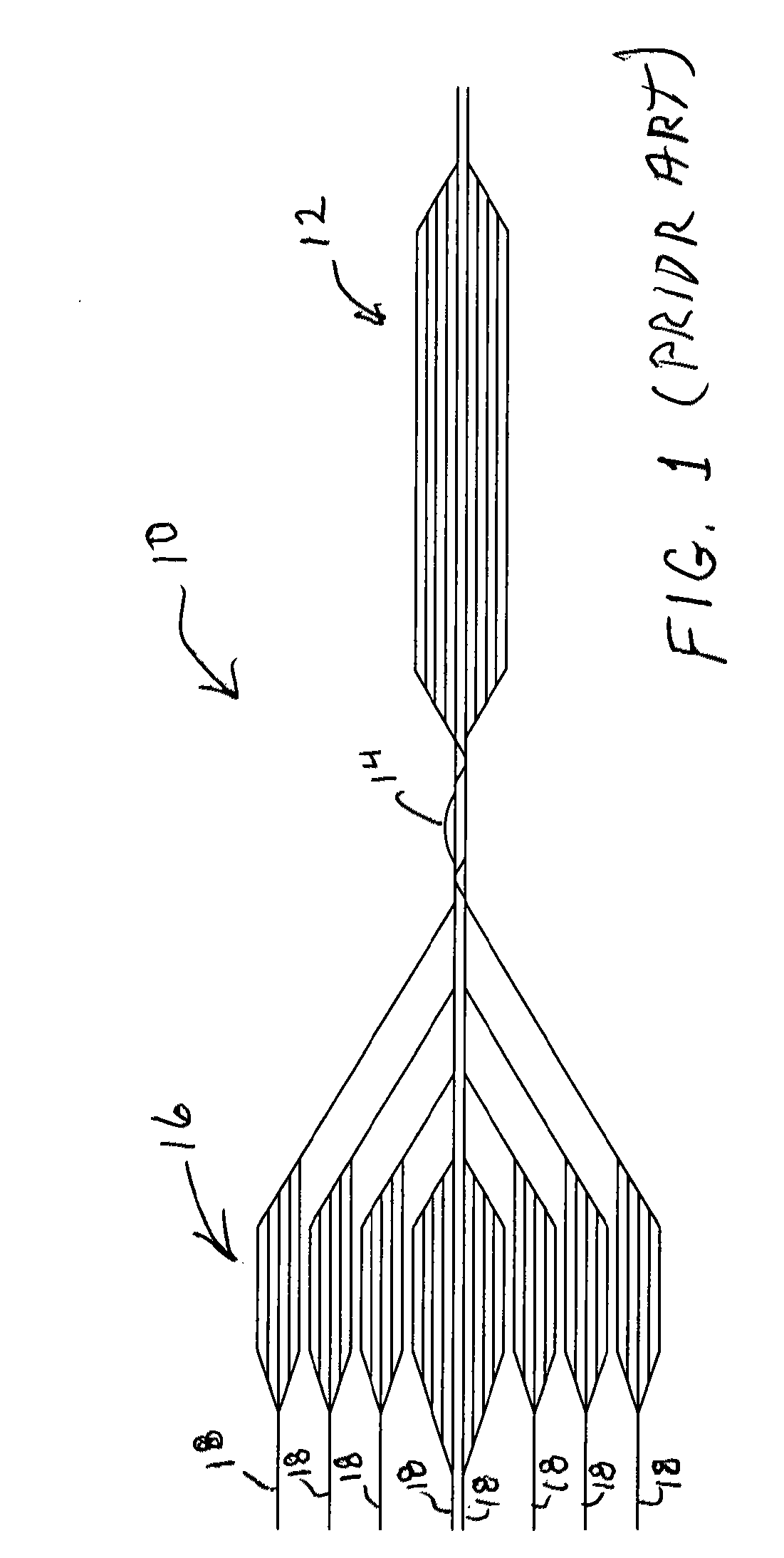

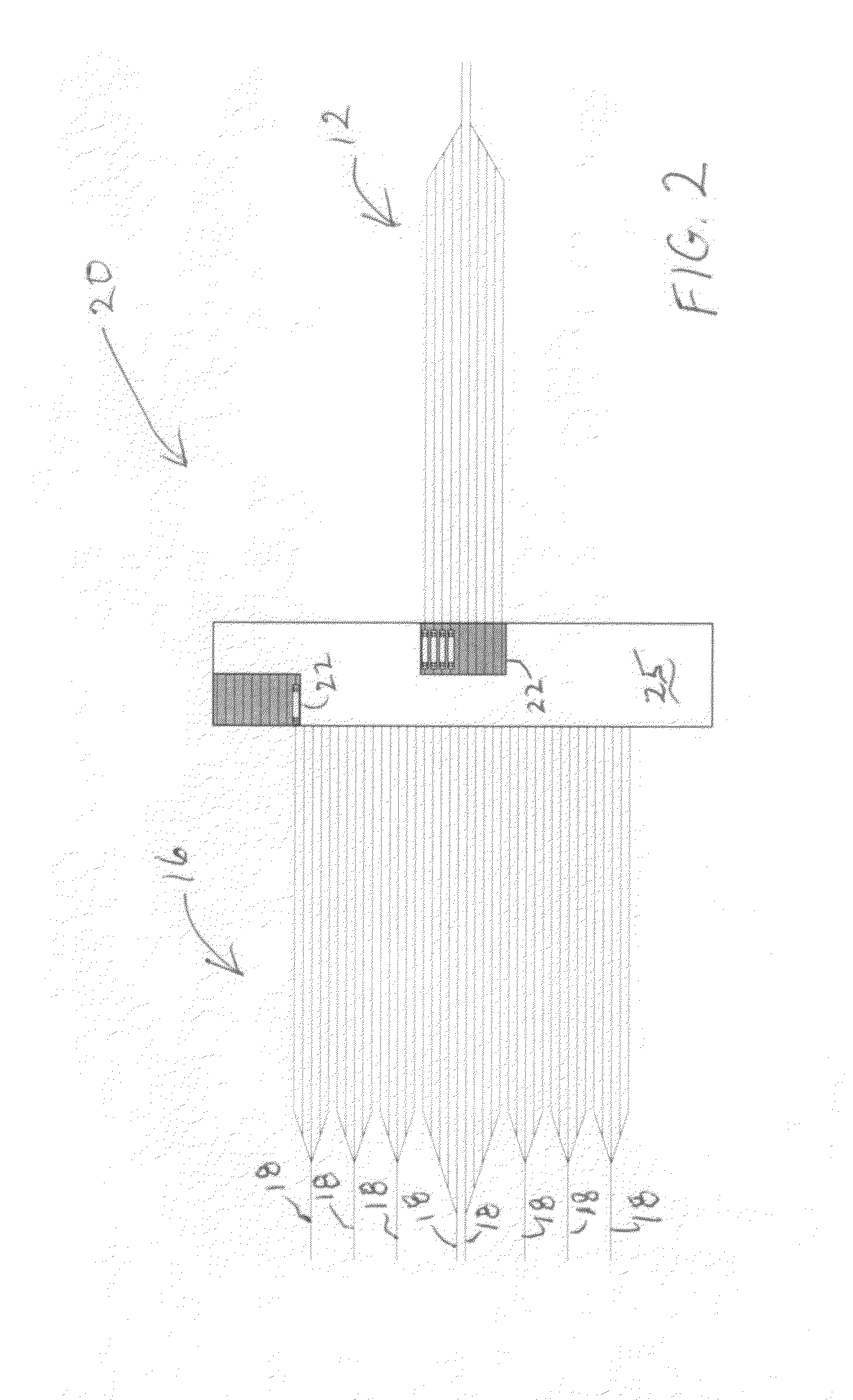

Train yard classification system

a classification system and train technology, applied in railway stations, trains, railway hauling devices, etc., can solve the problems of long time lapse between train arrival and departure, high labor intensity of train breaking process, so as to eliminate the burning of diesel fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The process of classification begins when an inbound train arrives on the new or retrofitted receiving yard track, which is constructed in accord with the present invention. The train stops and the locomotive units are uncoupled from the train in accordance with each railroad's rules and regulations.

[0057]At this point, preferably, an automatic system bleeds the air from the train. It is comprised of a robotic device that runs on a trackway alongside or underneath the inbound train. Connected to the device is a hydraulic arm that reaches out and pulls the bleed rod on the side of each car adjacent to the device until the air is depleted in the rail car. At this point, the car will roll freely because the brakes are released on the rail car. The device continues to be powered alongside the train, pulling the bleed rods until all the rail cars in the train have been bled of their air. The device preferably is operated by controller run by a computer program that uses logic to id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com