Brush cutter

a brush cutter and tooth technology, applied in the direction of peelers, cocoa, kitchen equipment, etc., can solve the problems of frequent maintenance frequent damage to the assembly and/or the collar, and early failure of the teeth, so as to increase the efficiency of the brush cutter, increase the life of the tooth, and facilitate tooth installation and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

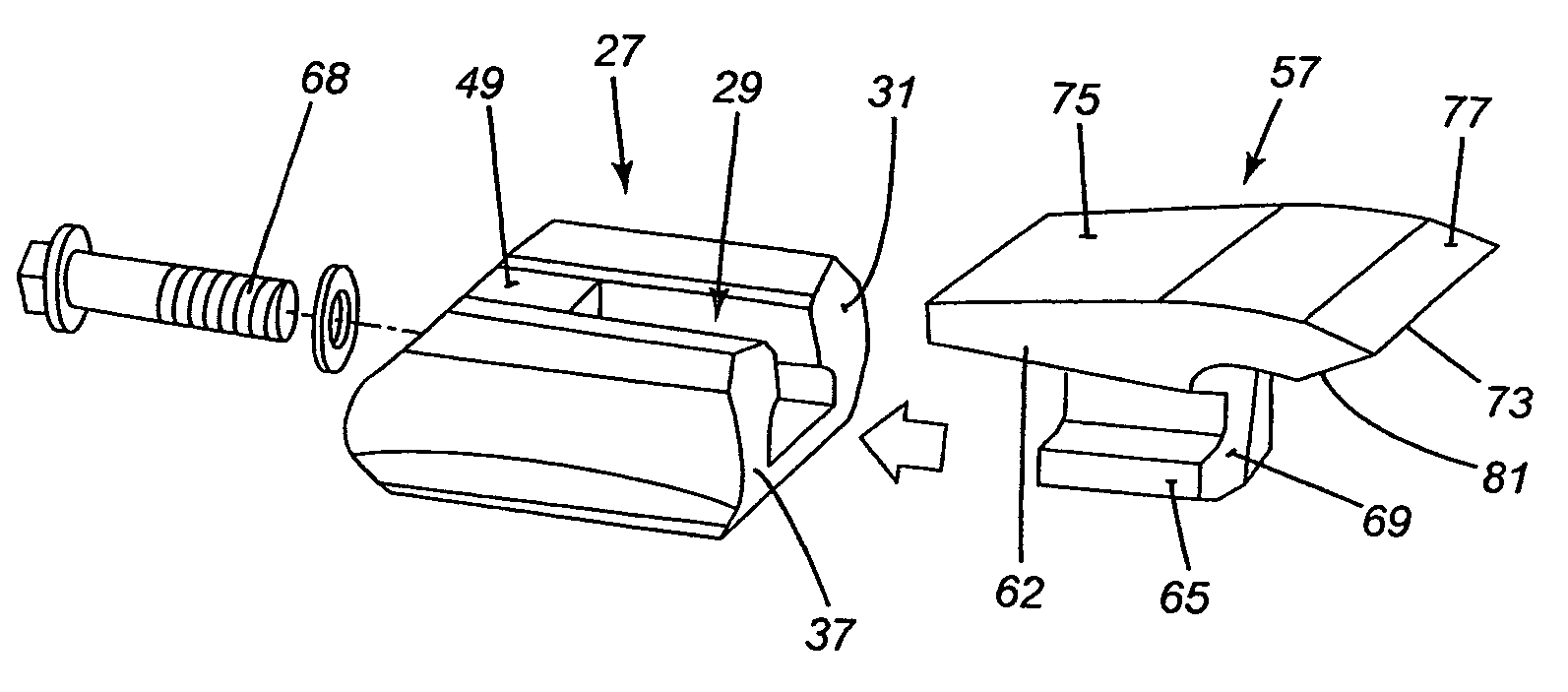

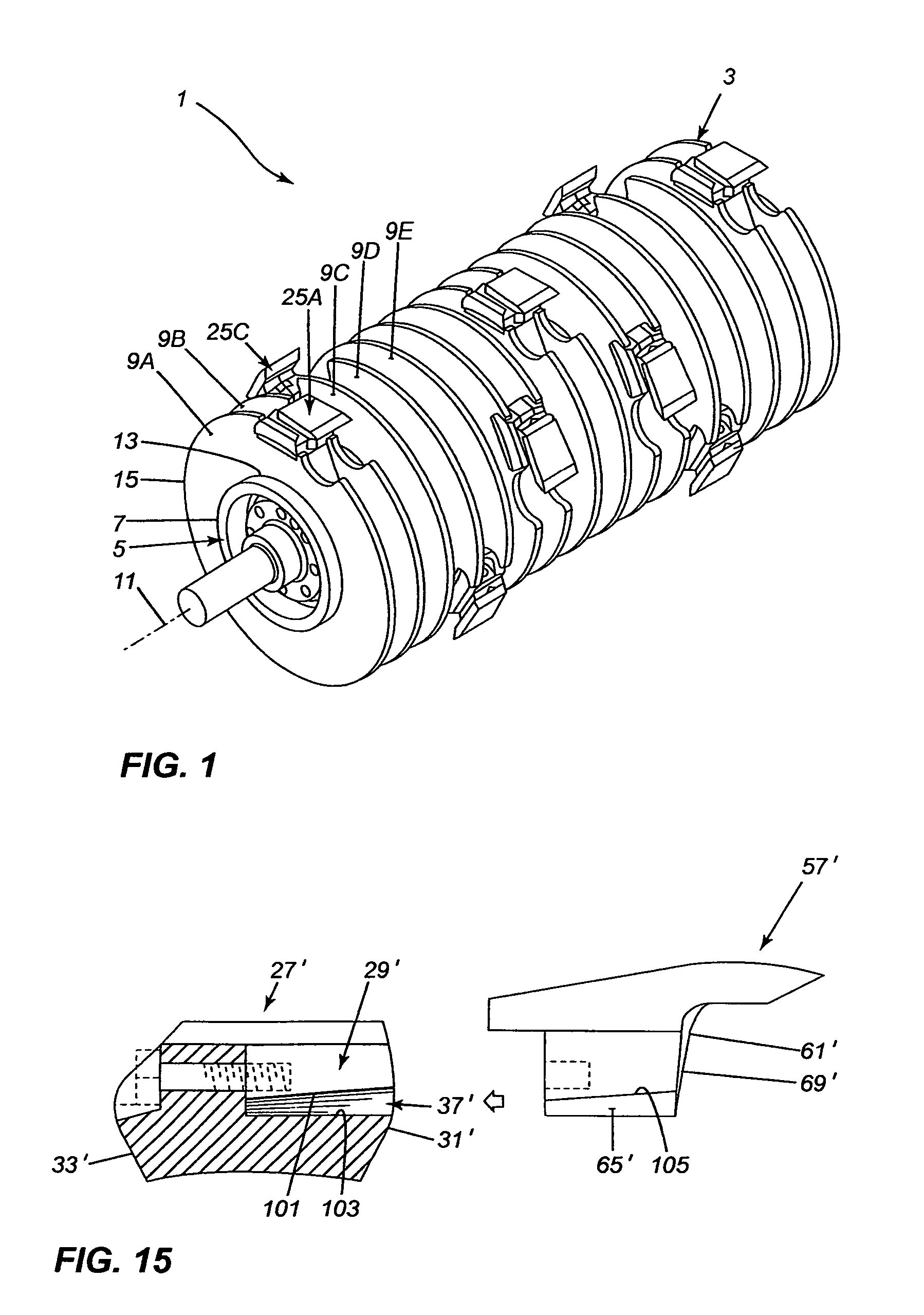

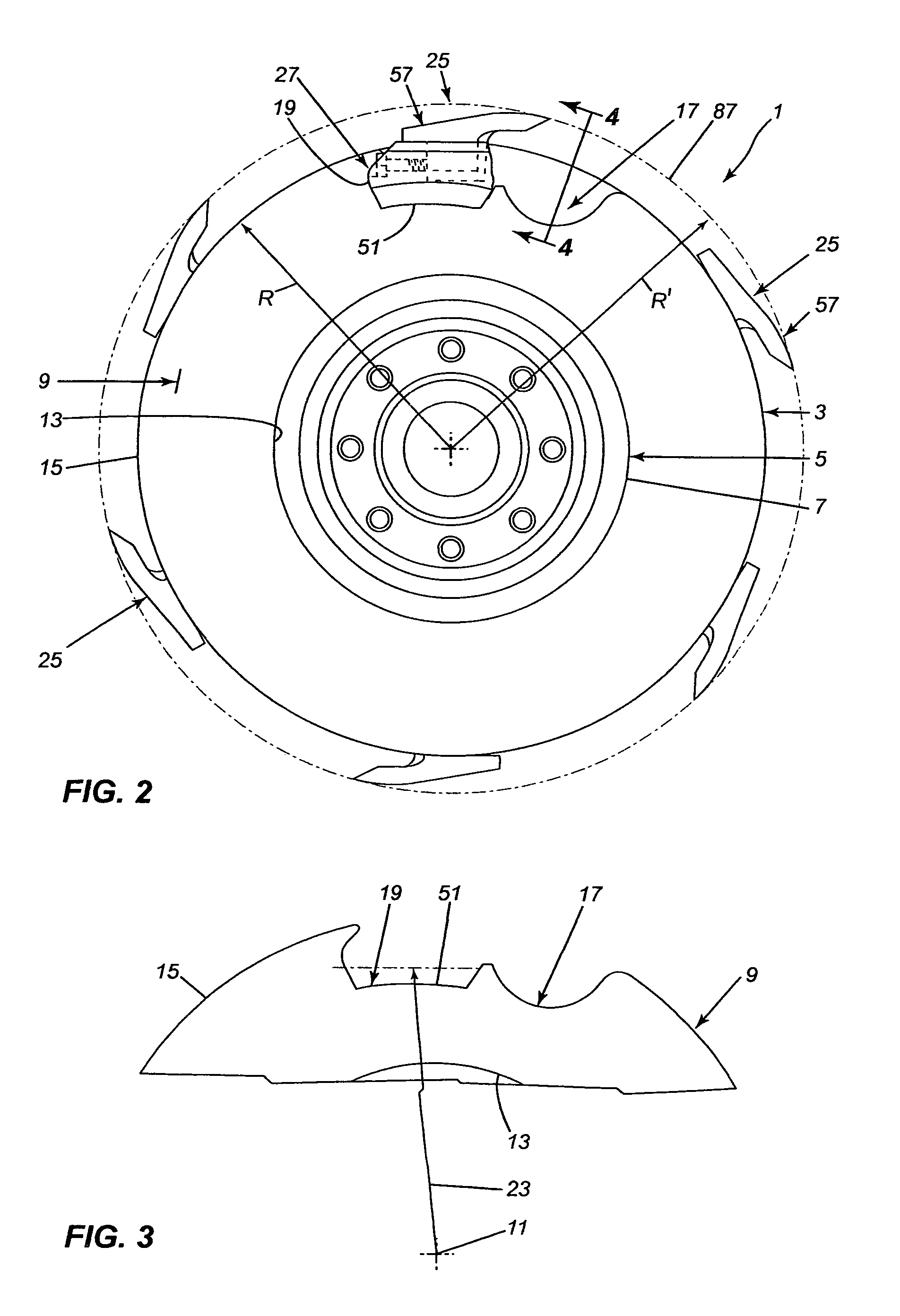

[0027]The brush cutter 1 of the present invention, as shown in FIGS. 1 to 3, has a rotatable drum 3. The drum 3 includes a central, tubular member 5 having a cylindrical surface 7. Annular collars 9 are mounted on the tubular member 5, the collars of equal size and equally spaced-apart and transverse to the longitudinal, central axis 11 of the tubular member 5. Each collar 9 has an inner circular periphery 13, sized to just receive the member 5 there through, and an outer periphery 15. The outer periphery 15 is also preferably circular but it could also have helical sections. Each collar 9 is welded onto the surface 7 of the tubular member 5. The drum 3 is mounted at its ends in any well known manner in a frame (not shown) that carries the drum and the drum is rotatable in the frame about its axis 11 by suitable drive means, (not shown).

[0028]Each collar 9 has at least one first cutout 17 extending radially inwardly from the outer periphery 15 of the collar. The cutout 17 has a gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com