Saddle clamp having electrical bonding character

a saddle clamp and electrical bonding technology, applied in the direction of connection contact member materials, coupling device connections, applications, etc., can solve the problems of improper grounding of one or more cables, fuel line electrical charges, and increase assembly time, so as to reduce the need for external electrical contact wire connections, reduce complexity, and enhance electrical coupling and charge dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

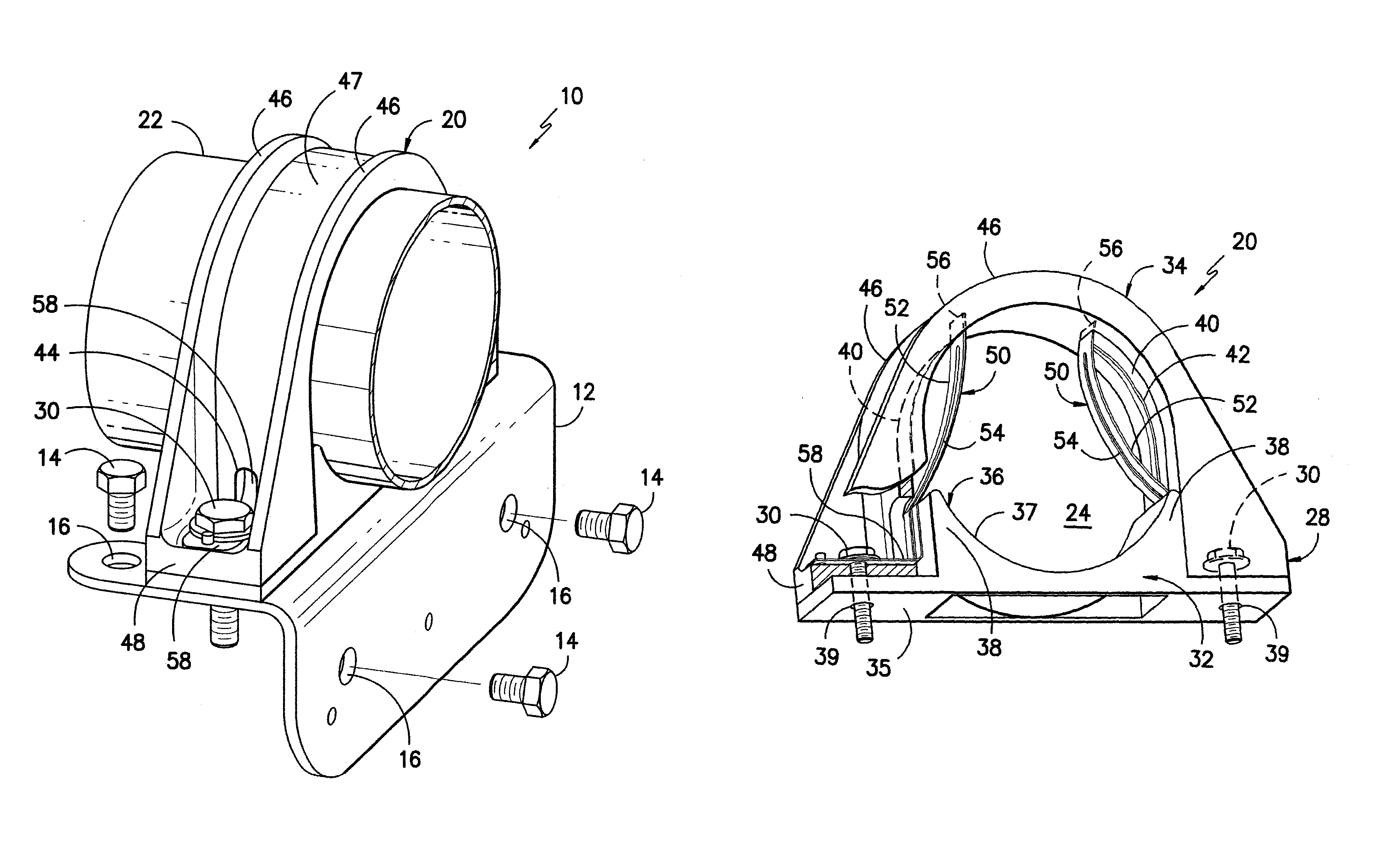

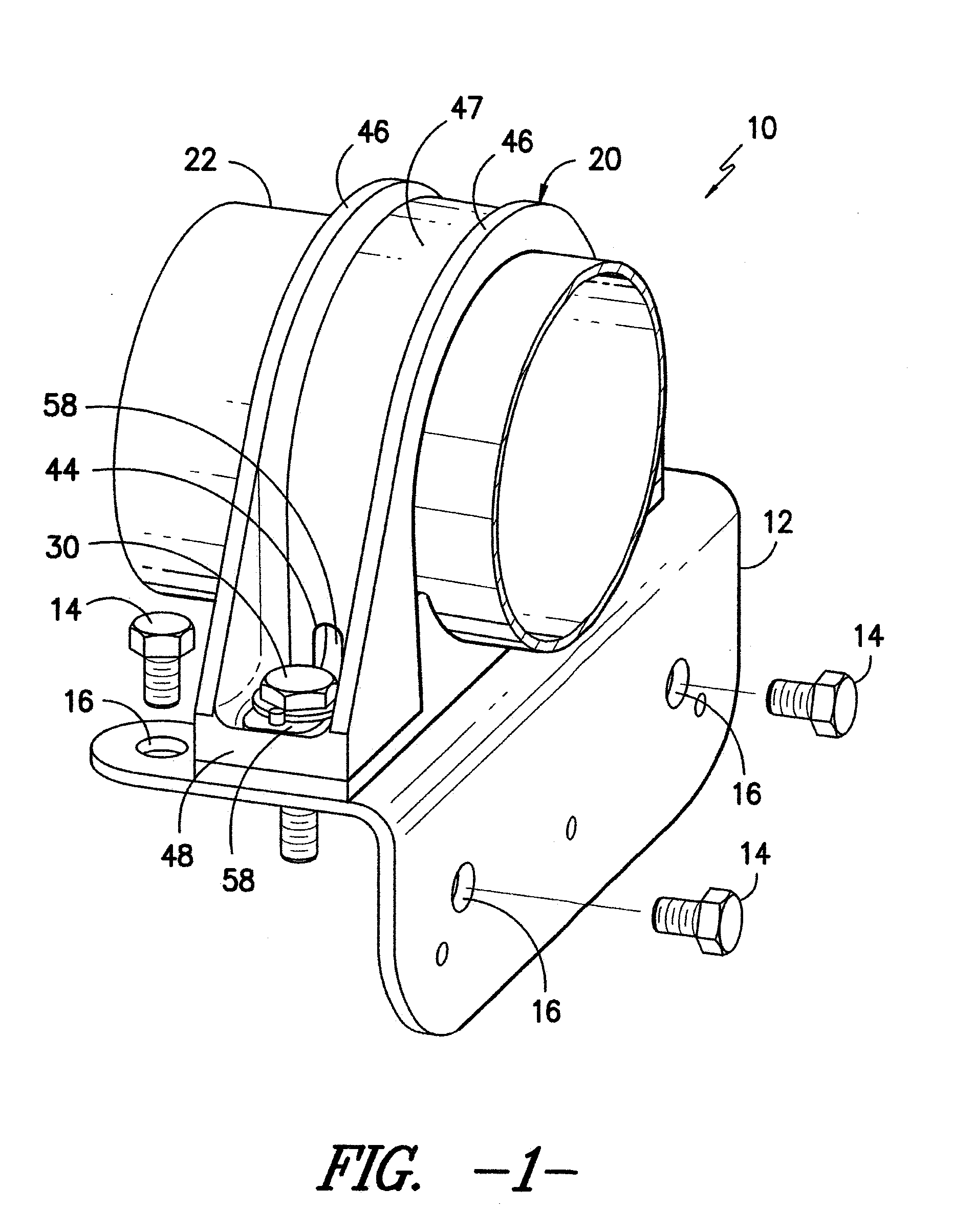

[0014]Exemplary embodiments of the invention will now be described in reference to the drawings, wherein like reference numerals designate like elements in the various views. Referring now to the drawings, in FIG. 1, an improved exemplary tube clamping system 10 is shown. As illustrated, the exemplary tube clamping system 10 incorporates a metal bracket 12 which may be attached to a portion of a metal support structure (not shown) by use of connection bolts 14 extending through attachment openings 16 in a manner as will be well known to those of skill in the art. By way of example only, the support structure may be a portion of an aircraft frame although the clamping system 10 may likewise be used in conjunction with virtually any support structure arrangement in numerous alternative environments of use. Without limitation, such alternative environments of use may include petrochemical plants, ground-based fuel storage depots, fuel tanker trucks and the like.

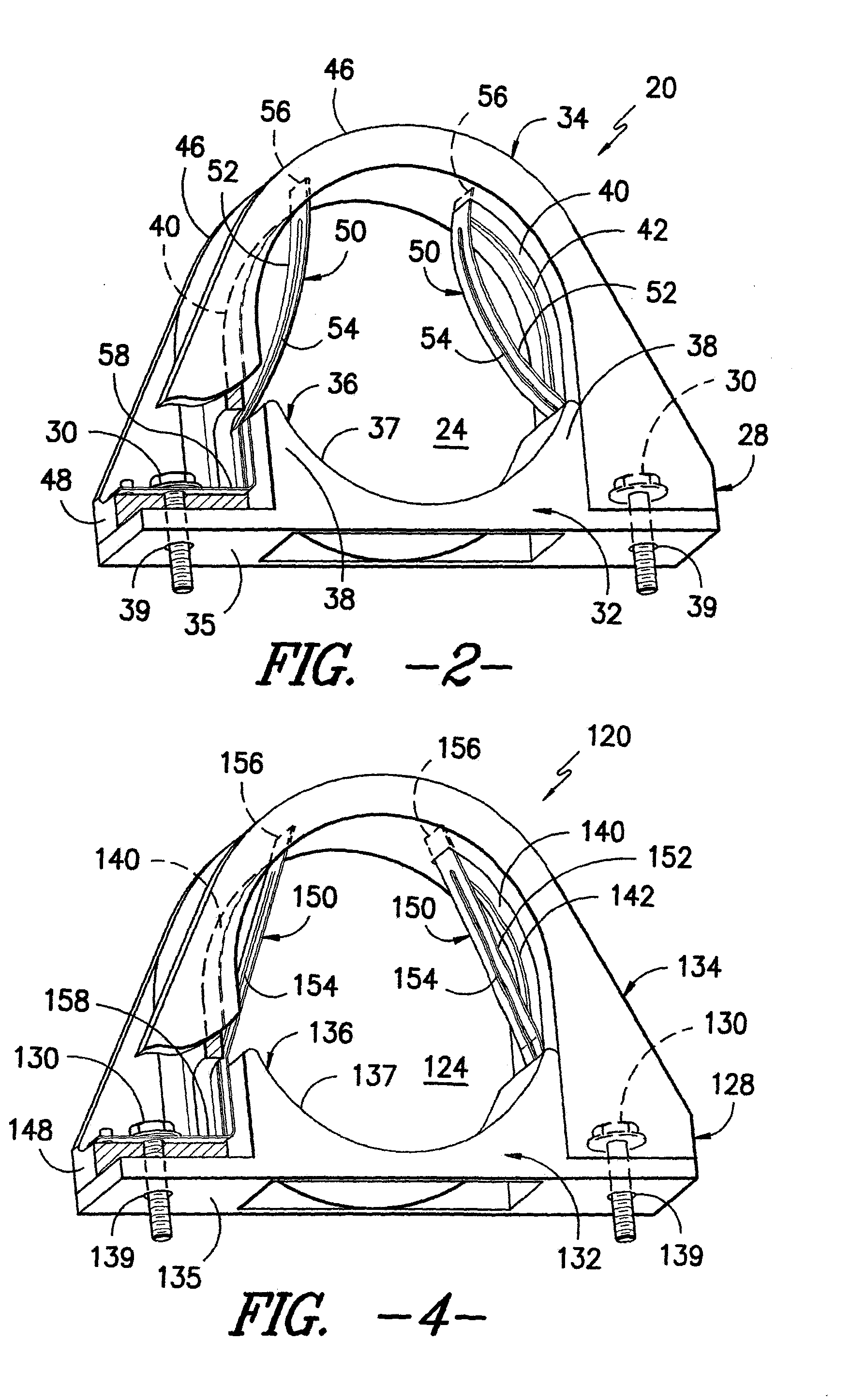

[0015]As shown, the exem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com