Production apparatus for manufacturing sensor package structure

a production apparatus and sensor technology, applied in electrical apparatus, semiconductor devices, radio frequency controlled devices, etc., can solve the problems of inability to control the flow of adhesive, the die fixed on the glass by the csp process needs to spend too much time to reduce the capacity of the package structure, and the cost of the sensor package structure. , to achieve the effect of increasing the capacity and yield reducing the cost of the sensor package structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

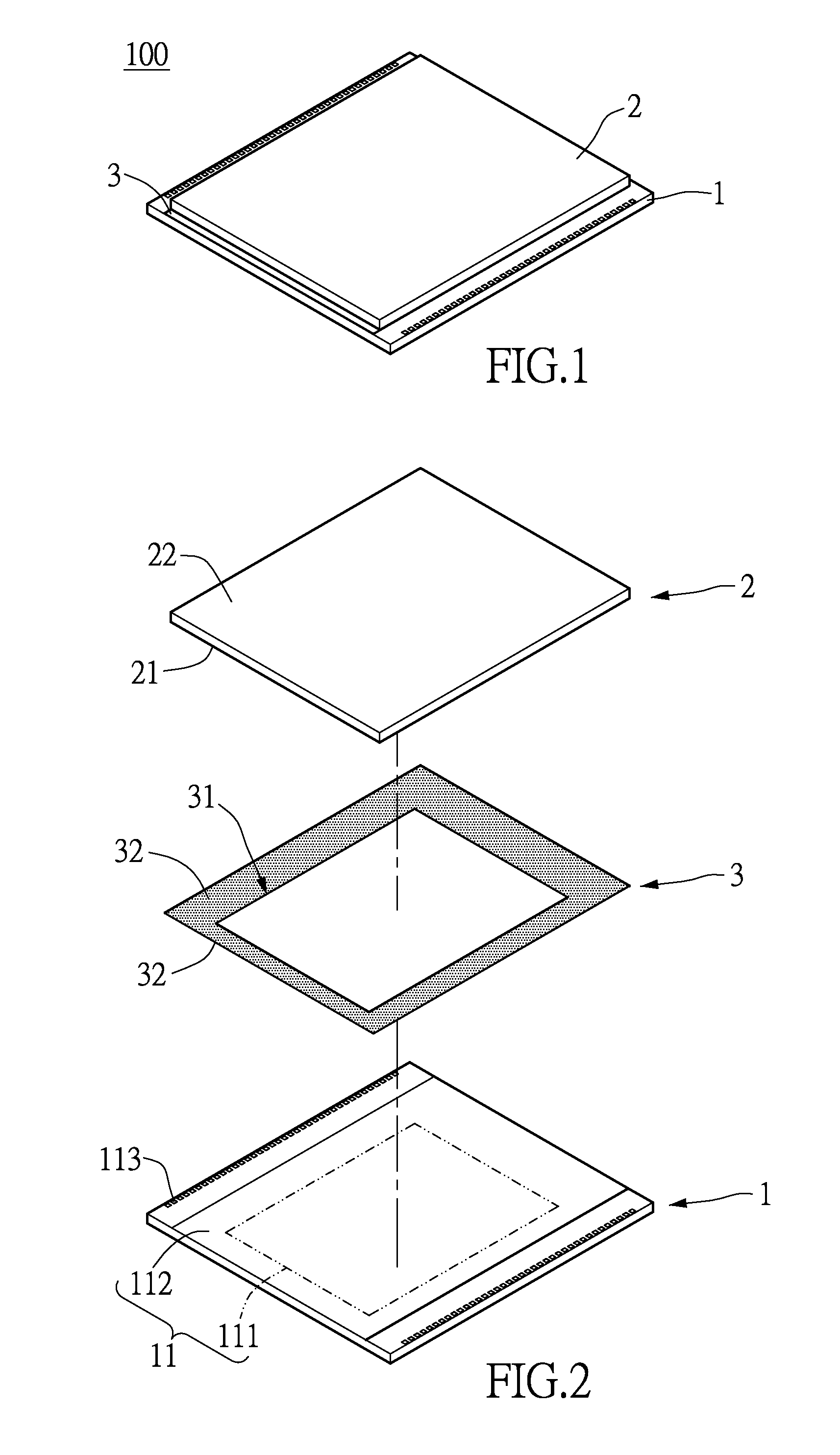

[0024]Please refer to FIGS. 1 and 2, which show a first embodiment of the instant disclosure. The instant embodiment provides a sensor package structure 100 including a sensing die 1, a light-filtering sheet 2, and a pressure-sensitive adhesive sheet 3, which has a rectangular annular shape. The following description discloses the detail construction of the sensing die 1, the light-filtering sheet 2, and the pressure-sensitive adhesive sheet 3 firstly, and then discloses the connecting relationship between the components of the sensor package structure 100.

[0025]The sensing die 1 in the instant embodiment takes a rectangular image sensing die for example. The sensing die 1 includes an active surface 11. The active surface 11 has a sensing region 111 and an annular connecting region 112 surrounding around the sensing region 111. The sensing die 1 includes a plurality of pads 113 respectively exposed from two opposite portions of the connecting region 112 (i.e., the ...

second embodiment

[Second Embodiment]

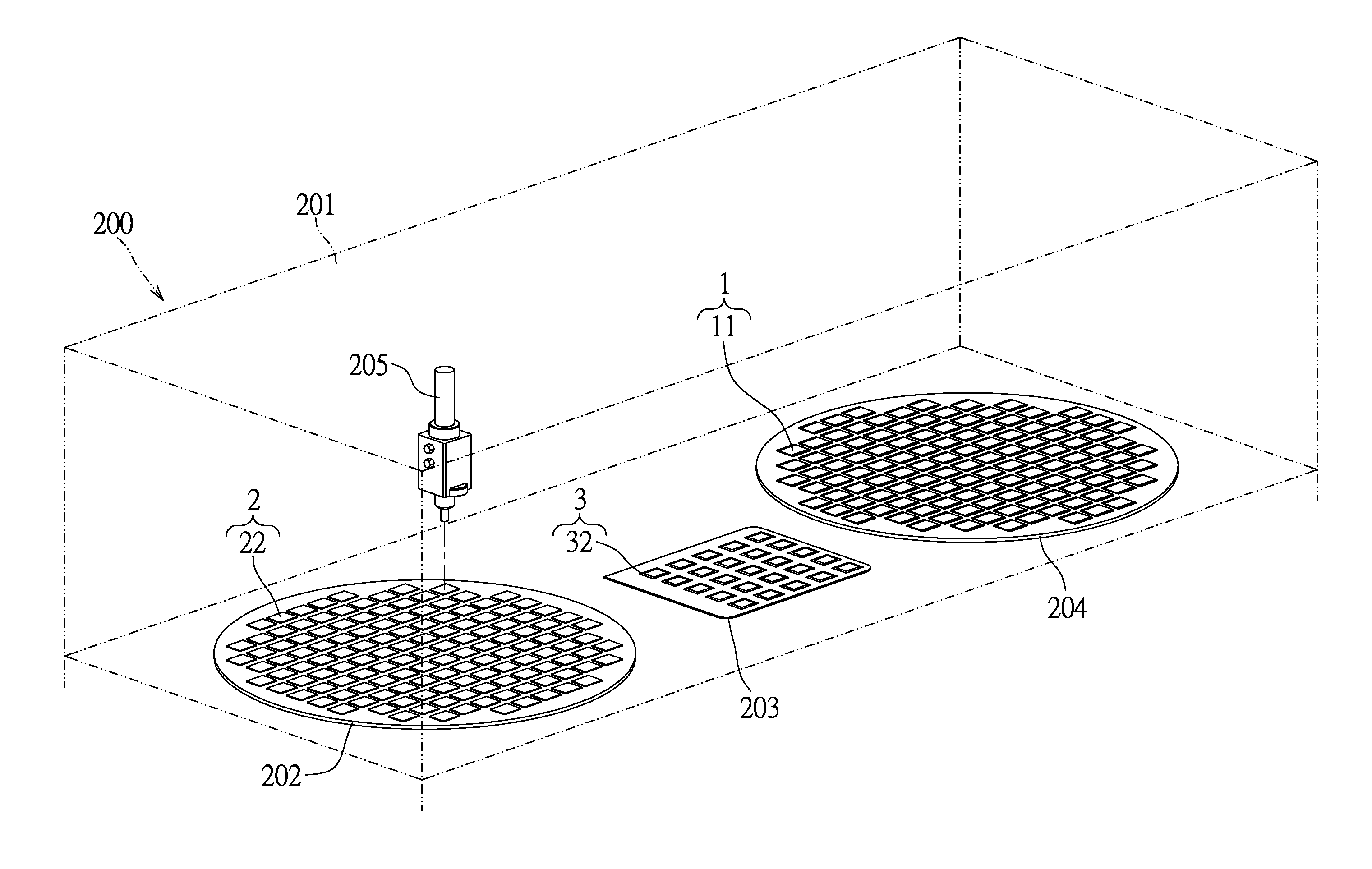

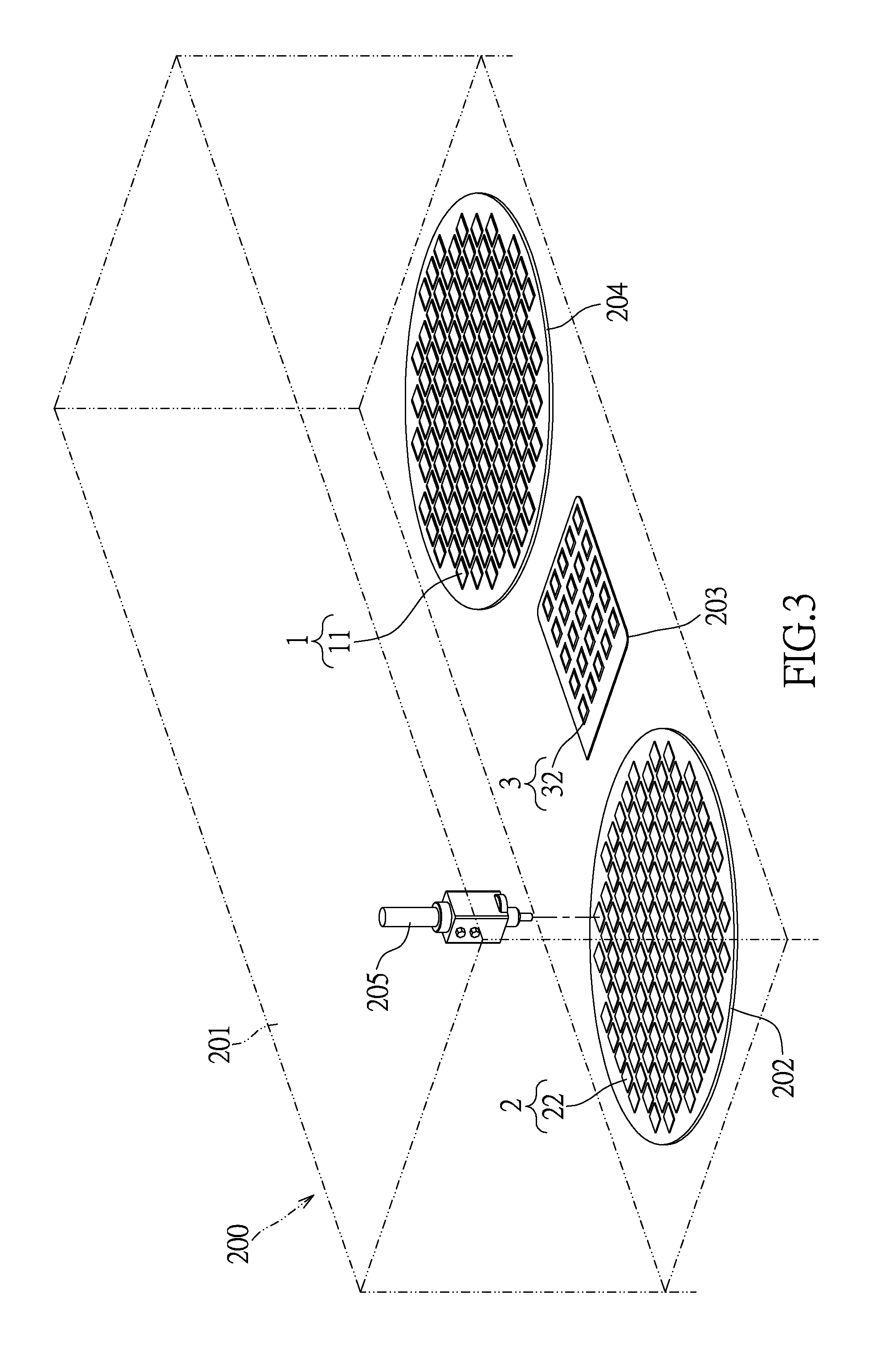

[0038]Please refer to FIGS. 3 through 10, which show a second embodiment of the instant disclosure. The second embodiment provides a production apparatus 200 used for manufacturing the sensor package structure 100 disclosed in the first embodiment. The sensor package structure 100 has been disclosed in the first embodiment, so that the instant embodiment does not state the construction of the sensor package structure 100 again.

[0039]The production apparatus 200 includes a machine body 201, a first workbench 202, a second workbench 203, a third workbench 204, and a shifting member 205. The first workbench 202, the second workbench 203, the third workbench 204, and the shifting member 205 are installed on the machine body 201, and the machine body 201 includes a driving module (not shown) for providing the three dimensional movement of the shifting member 205. The driving module is a conventional feature, so the instant embodiment does not state in detail.

[0040]The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure-sensitive | aaaaa | aaaaa |

| pressure- | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com