Dryer for clothes

a clothes dryer and clothes technology, applied in the field of clothes dryers, can solve the problems of affecting the drying performance of clothes, and increasing power consumption, so as to achieve the effect of improving drying performance and reducing siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Hereinafter, a dryer for clothes including a lint filter cleaning device according to an embodiment will be described in detail with reference to the accompanying drawings. Also, an air vented dryer will be described as an example of the dryer for the clothes including the lint filter cleaning device according to an embodiment. However, the lint filter cleaning device according to an embodiment may be applied to various types of dryers for clothes including a forced convection dryer as well as the air vented dryer.

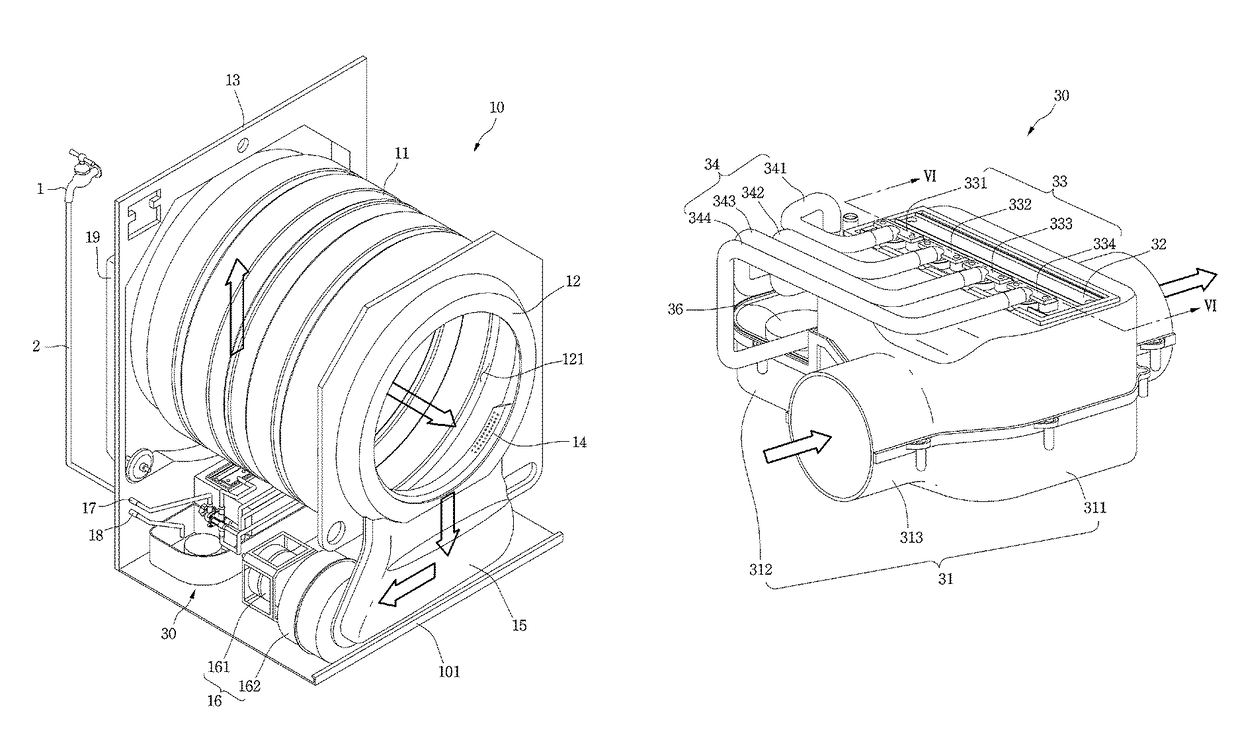

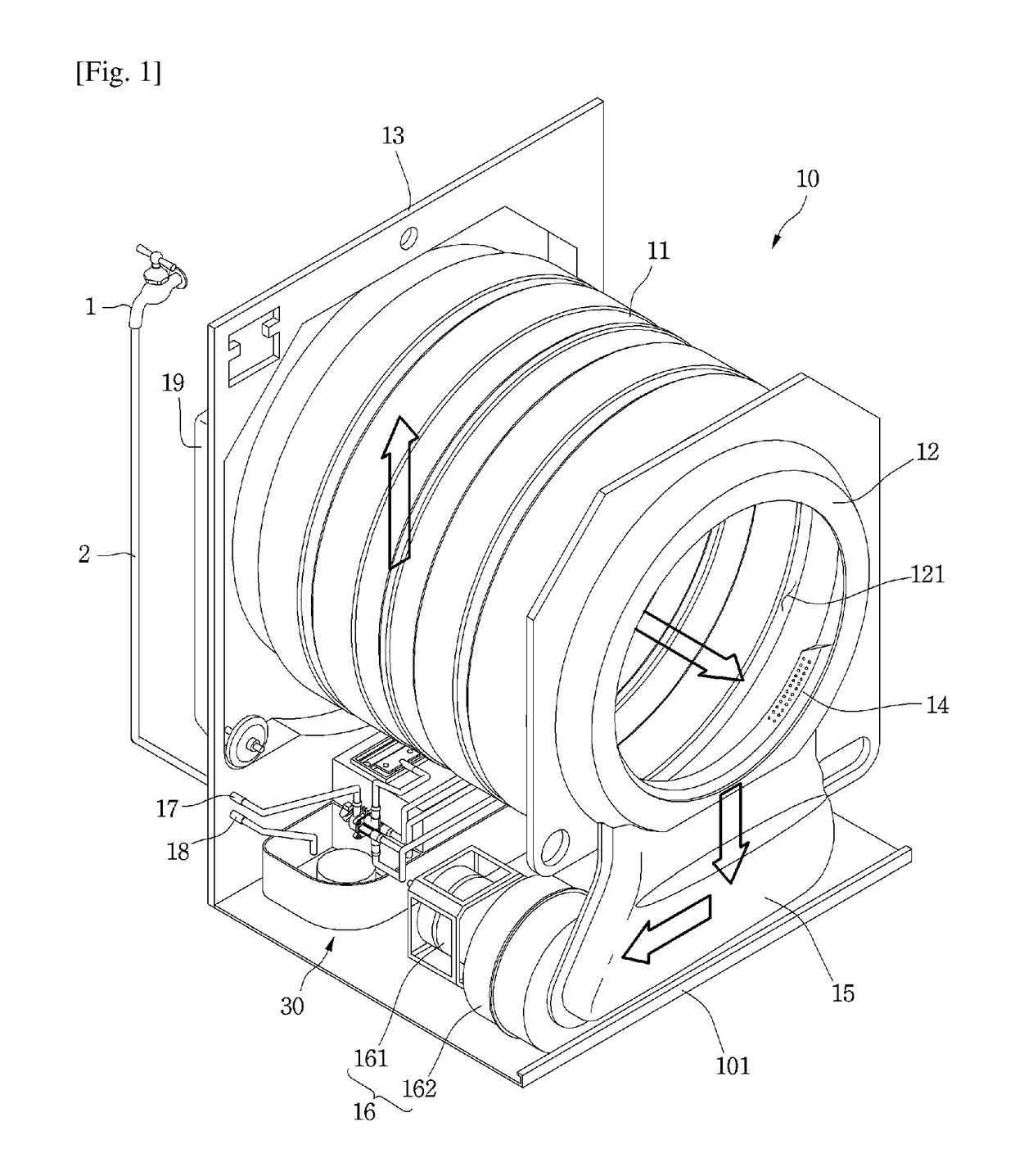

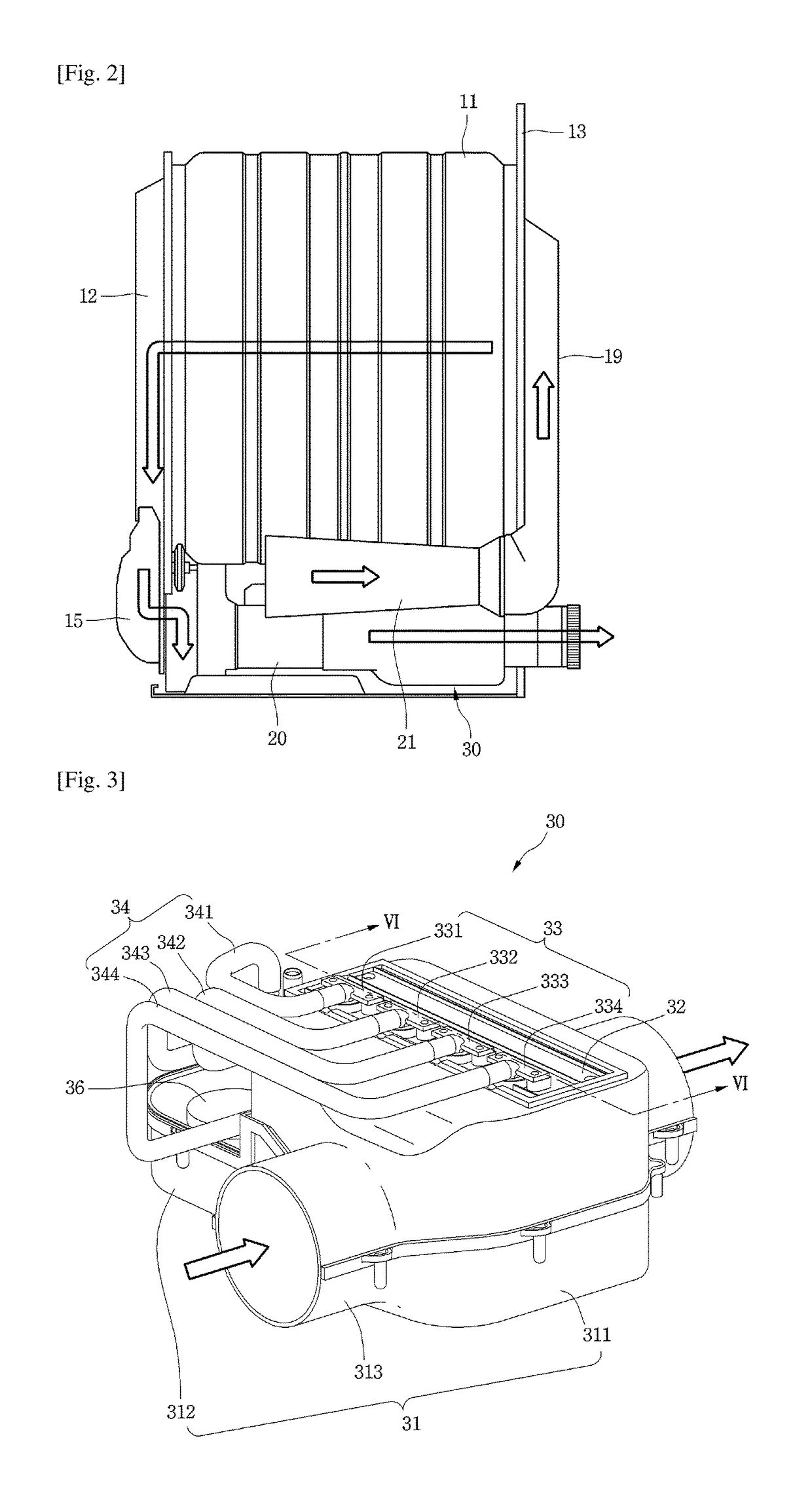

[0027]FIG. 1 is a perspective view of a dryer for clothes including a lint filter cleaning device according to an embodiment, and FIG. 2 is a side view of the dryer for the clothes.

[0028]Referring to FIGS. 1 and 2, a dryer for clothes (hereinafter, referred to as a “clothes dryer”) including a lint filter cleaning device according to an embodiment may include a drying drum 11 into objects to be dried are put, a front cabinet 12 supporting a front part of the drying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com