Some uses of microencapsulation for electric paper

a technology of microencapsulation and electric paper, which is applied in the field of some uses of microencapsulation for electric paper, can solve the problems of affecting the appearance, the final product lacks some of the optical and tactile properties of paper, and the gel is soft and lacks durability, so as to achieve convenient conformation and greater flexibility of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

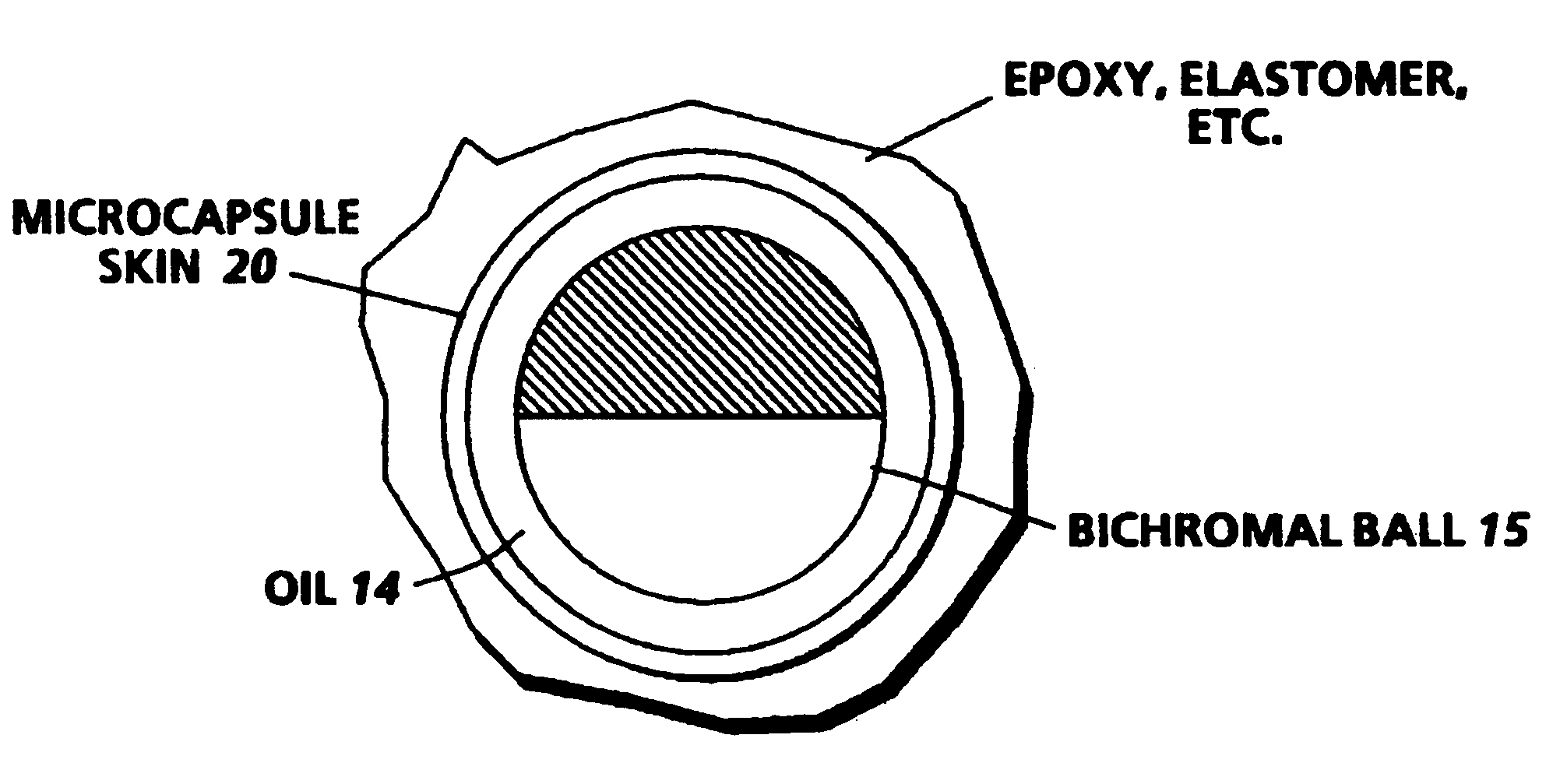

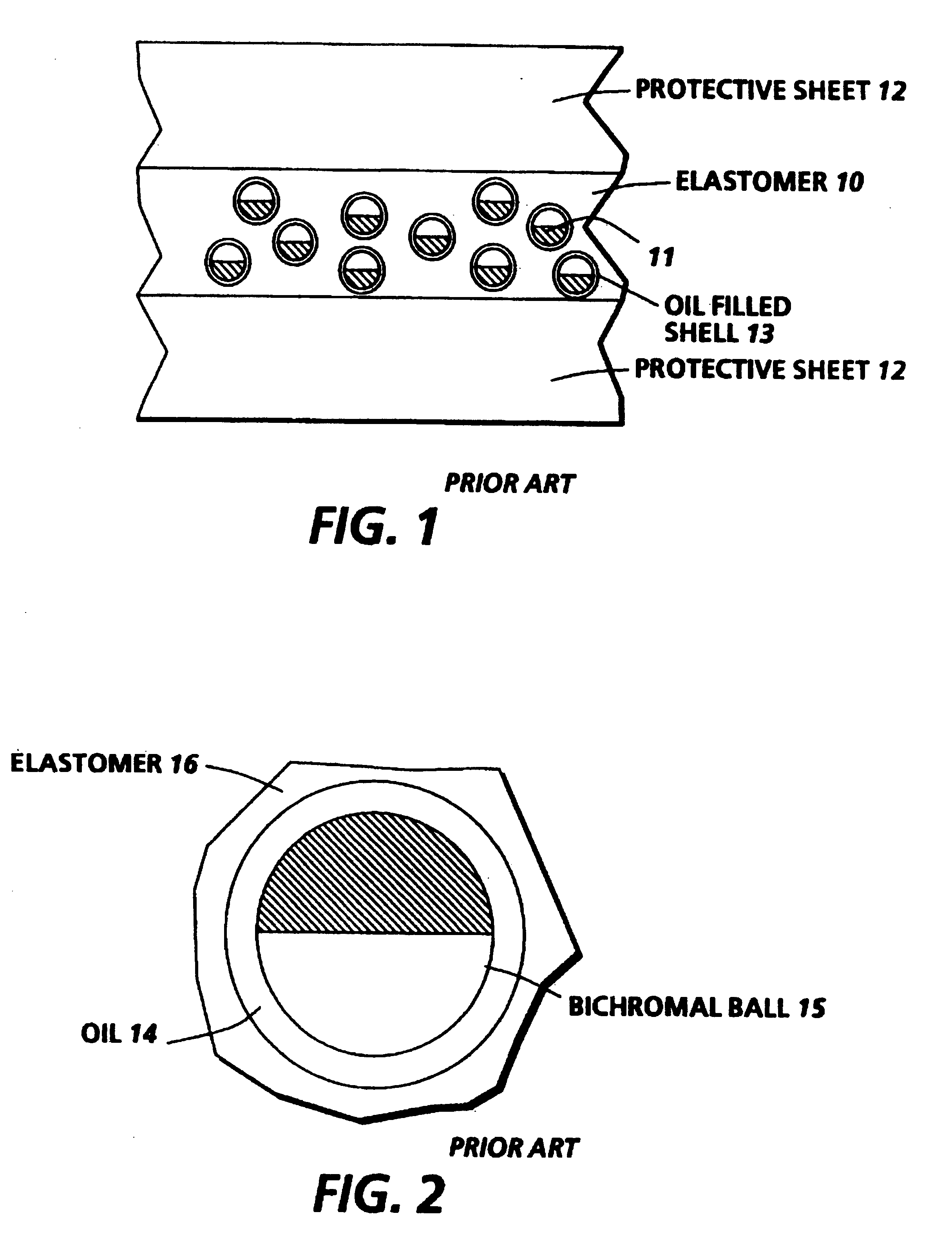

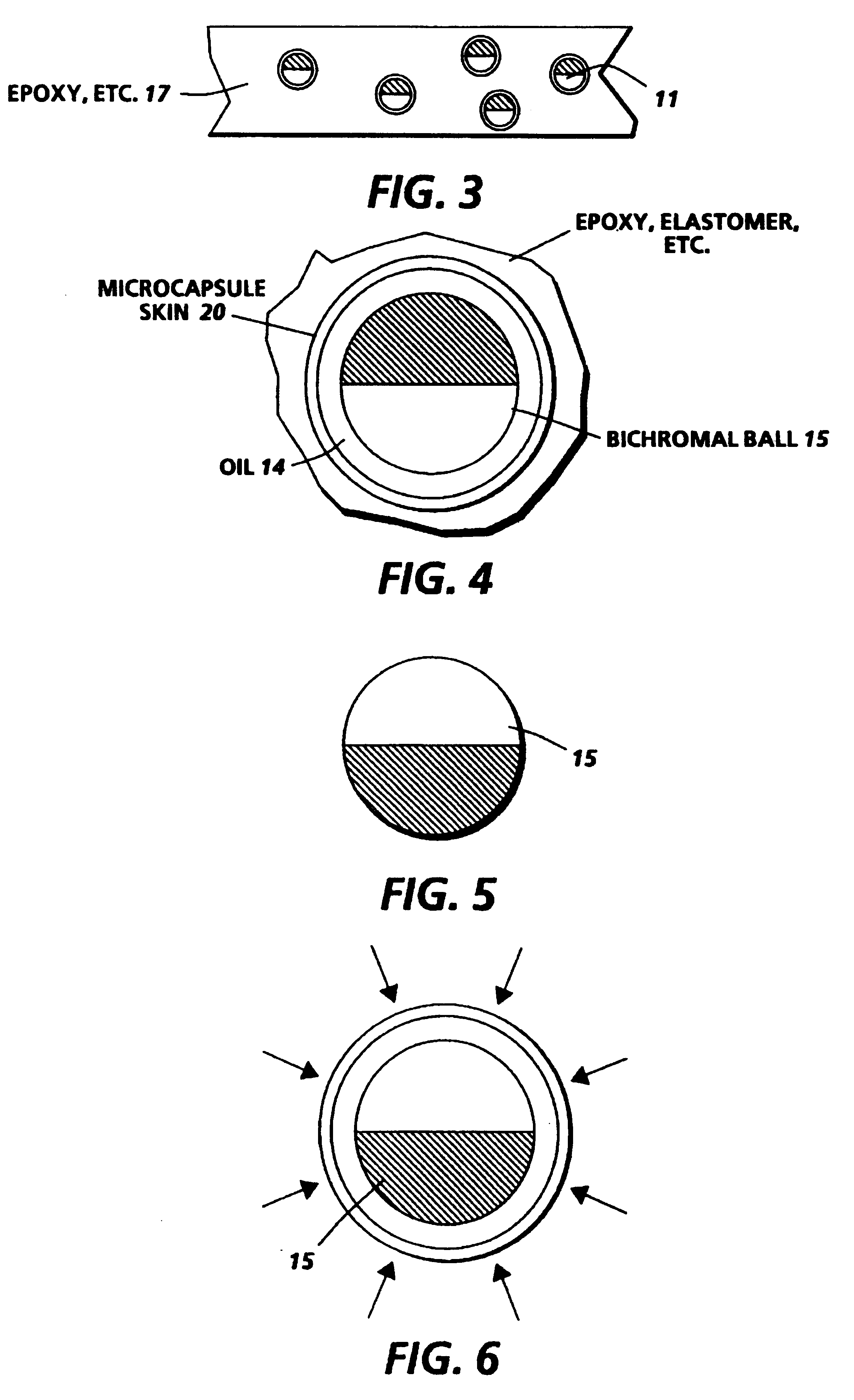

FIG. 1 is a cross section of the prior art version of this twisting ball display. A large number of bichromal balls 11 are mixed into an uncured elastomer which is subsequently spread into a thin layer 10 and cured to form a solid sheet of elastomer. Next this elastomer is soaked in a plasticizing oil which swells the elastomer but generally does not effect the bichromal balls. The result is that a spherical cavity 13 opens up around each bichromal ball, and this cavity subsequently fills with the plasticizing liquid. Finally the plasticized elastomer is bonded between two protective, transparent sheets of plastic or glass, 12, one or both of which might have a transparent .[.condicting.]. .Iadd.conducting .Iaddend.coating. FIG. 2 is an enlarged view of the bichromal ball 15 surrounded by plasticizing oil 14 within a cavity in elastomer 16.

The substrate material used in the prior art twisting ball display was largely limited to the class of elastomer materials, because these materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| electrical characteristics | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com