Apparatus for manufacturing carbonated water

a technology for carbonated water and manufacturing apparatus, which is applied in the direction of carburetating air, separation process, transportation and packaging, etc., can solve the problems of inability to make a large-sized carbonated beverage manufacturing apparatus to elongate the dispersion distance, and the carbonic acid gas may easily be separated, so as to achieve the effect of less dispersion rapid carbonation of water, and high inclusion rate of carbonic acid gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

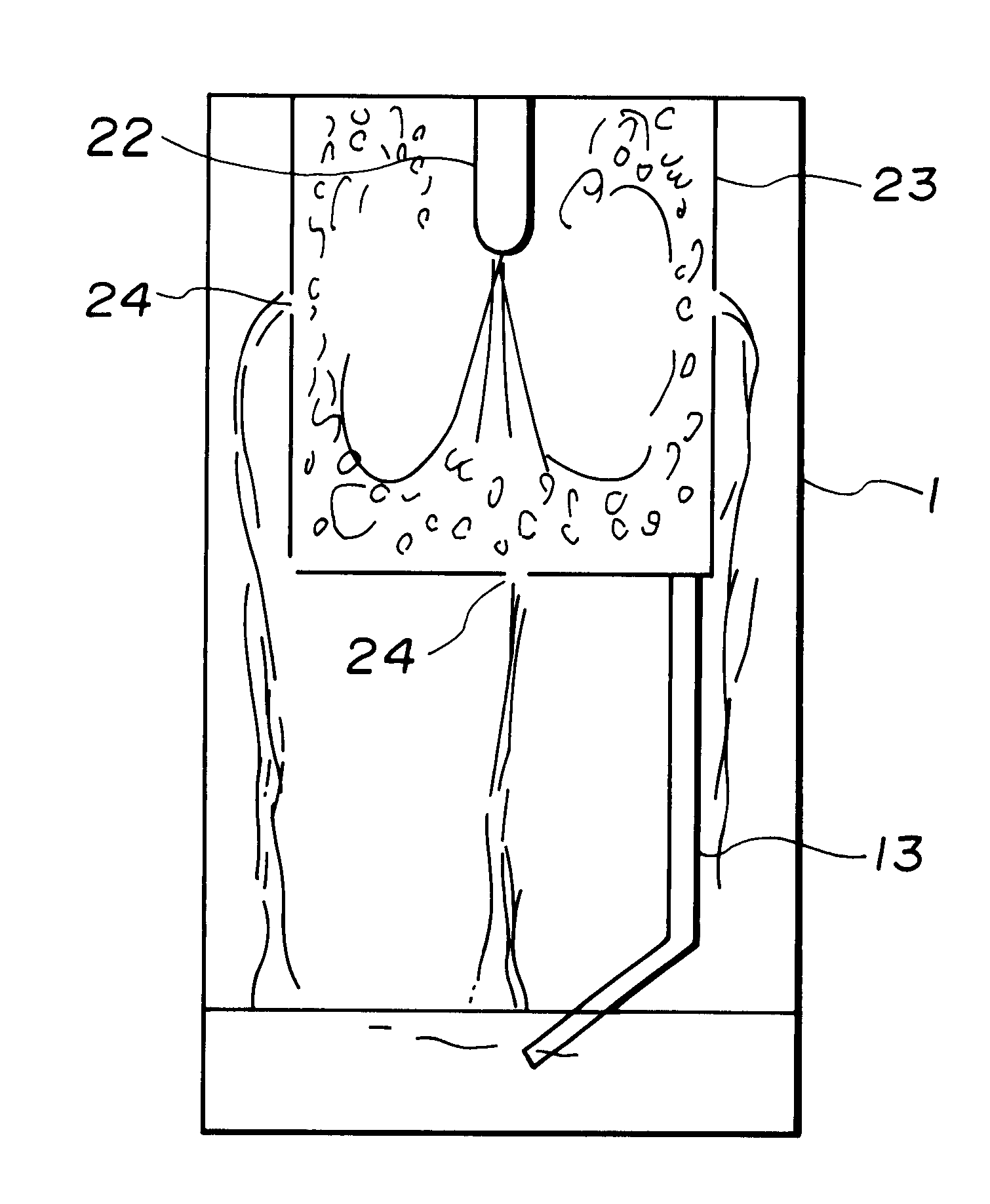

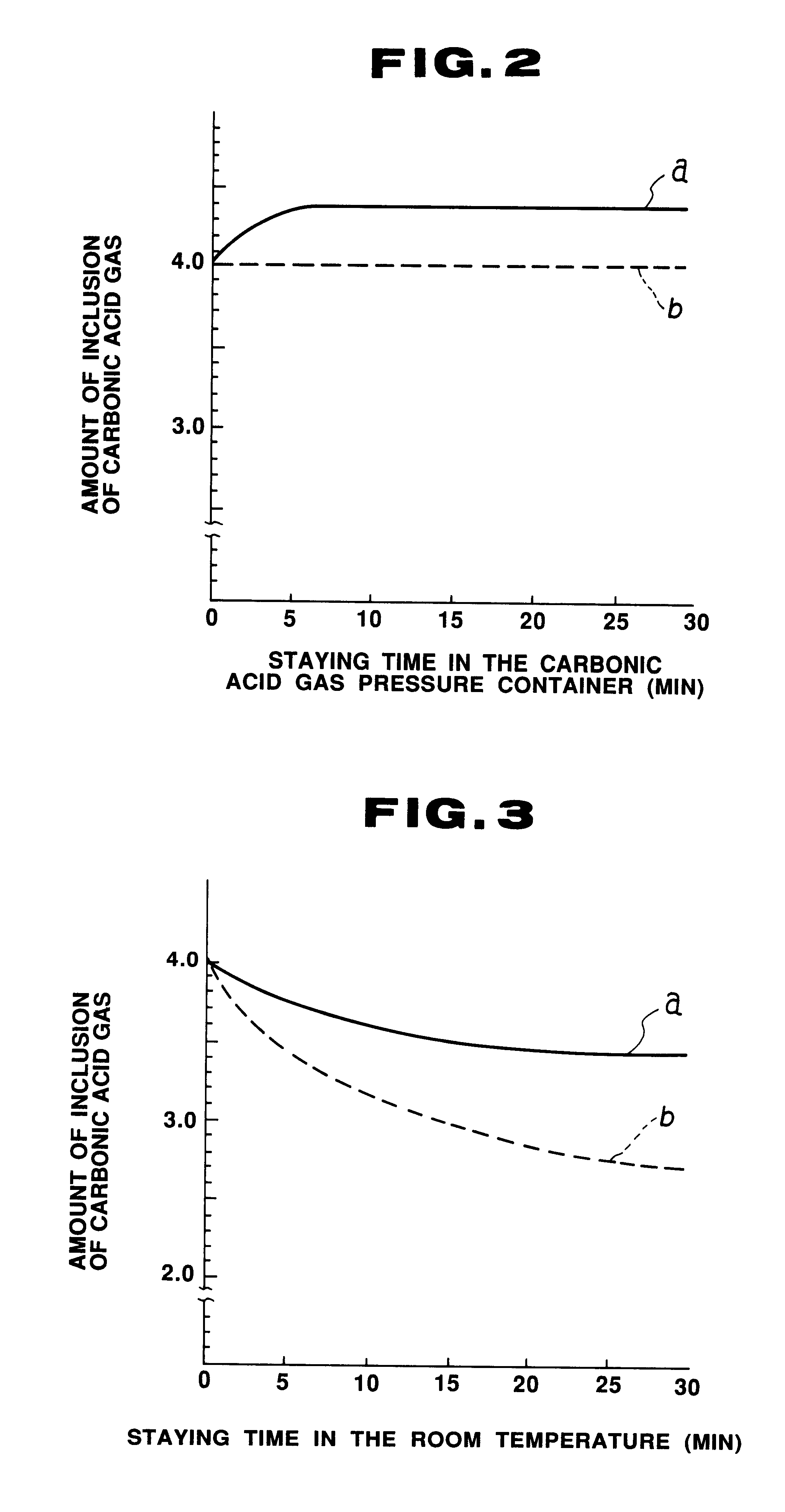

In the present invention, a large amount of air bubbles with their diameter being less than 1 mm are generated by feeding water into a carbonic acid gas container at a speed of at least more than 5 cm / sec in the form of water droplets mainly with a diameter larger than 0.01 mm, and smaller than 0.5 mm and striking the water against water accumulated in the carbonic acid gas pressure container. Carbonic acid gas is absorbed in the bubbles to enable carbonated water having a high rate of inclusion of carbonic acid gas and less amount of dispersion to be produced.

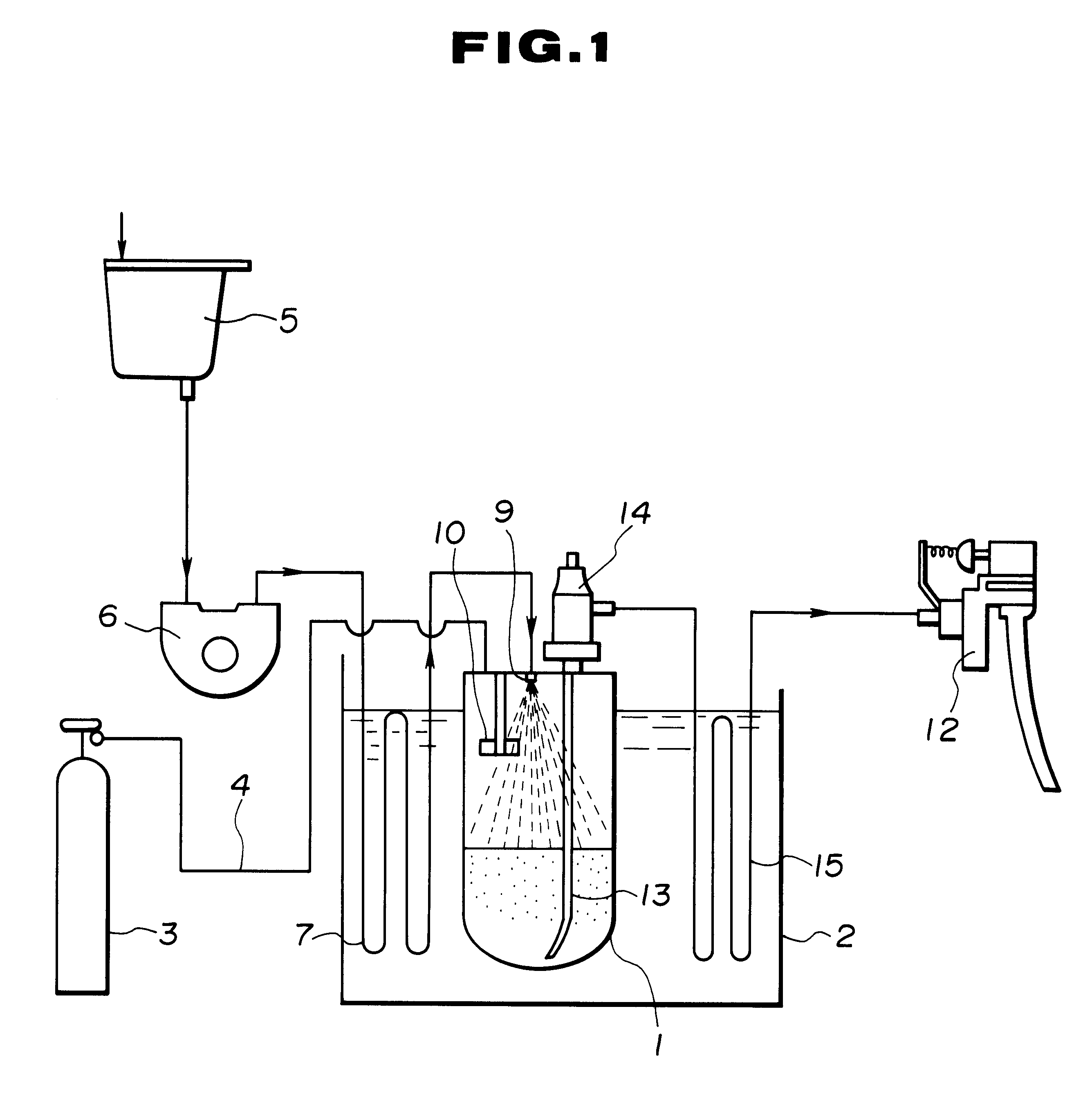

Referring now to FIGS. 1 to 3, the preferred embodiment of the present invention will be described.

A carbonic acid gas container 1 is immersed in a cooling water tank 2 and its temperature is kept cold. To this carbonic acid gas pressure container 1 is supplied carbonic acid gas under pressure from a carbonic acid gas cylinder 3 through a carbonic acid gas feeding pipe passage 4, and further to the carbonic acid gas pressure c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com