Lightweight handle

a light-weight, handle technology, applied in the direction of sealing, cell components, containers preventing decay, etc., can solve the problems of relatively high manufacturing cost and without drawbacks, and achieve the effect of eliminating any relative movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

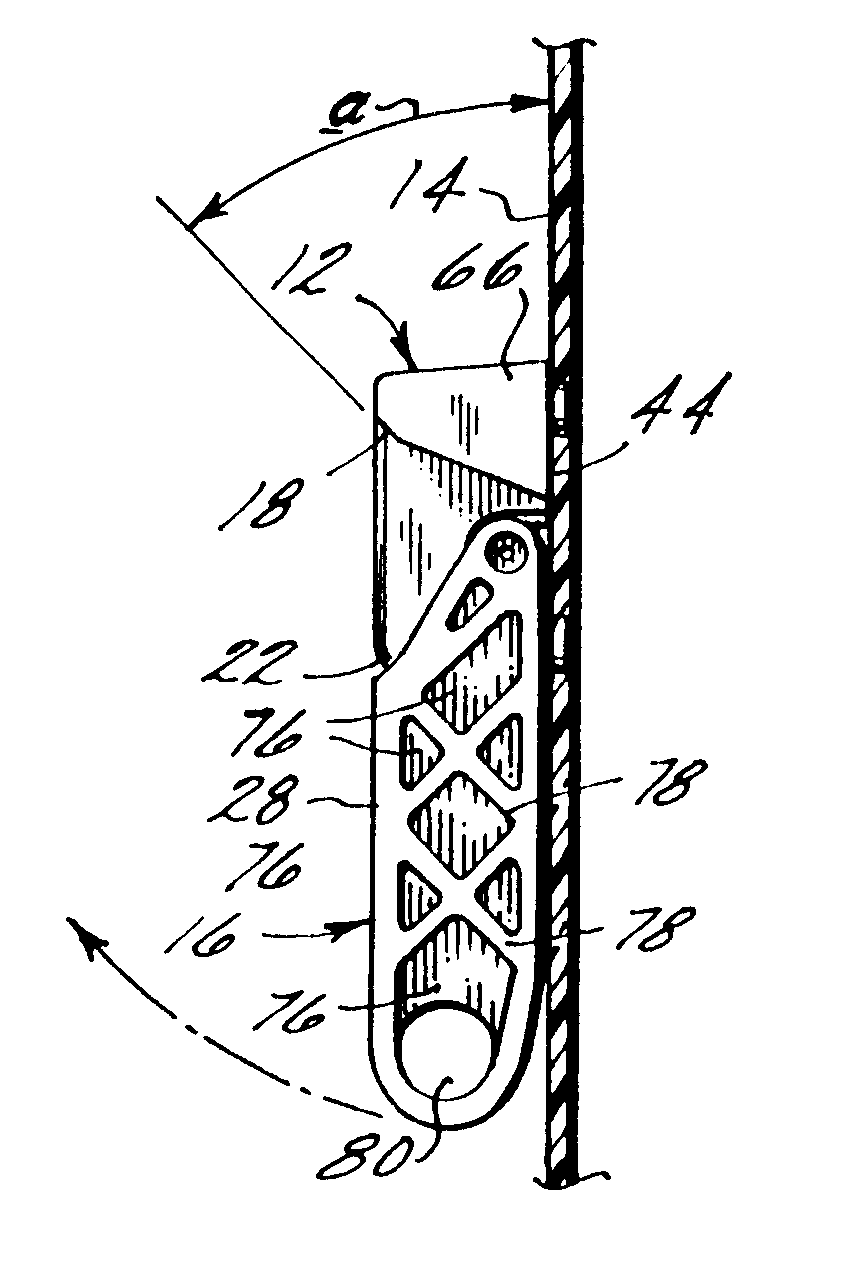

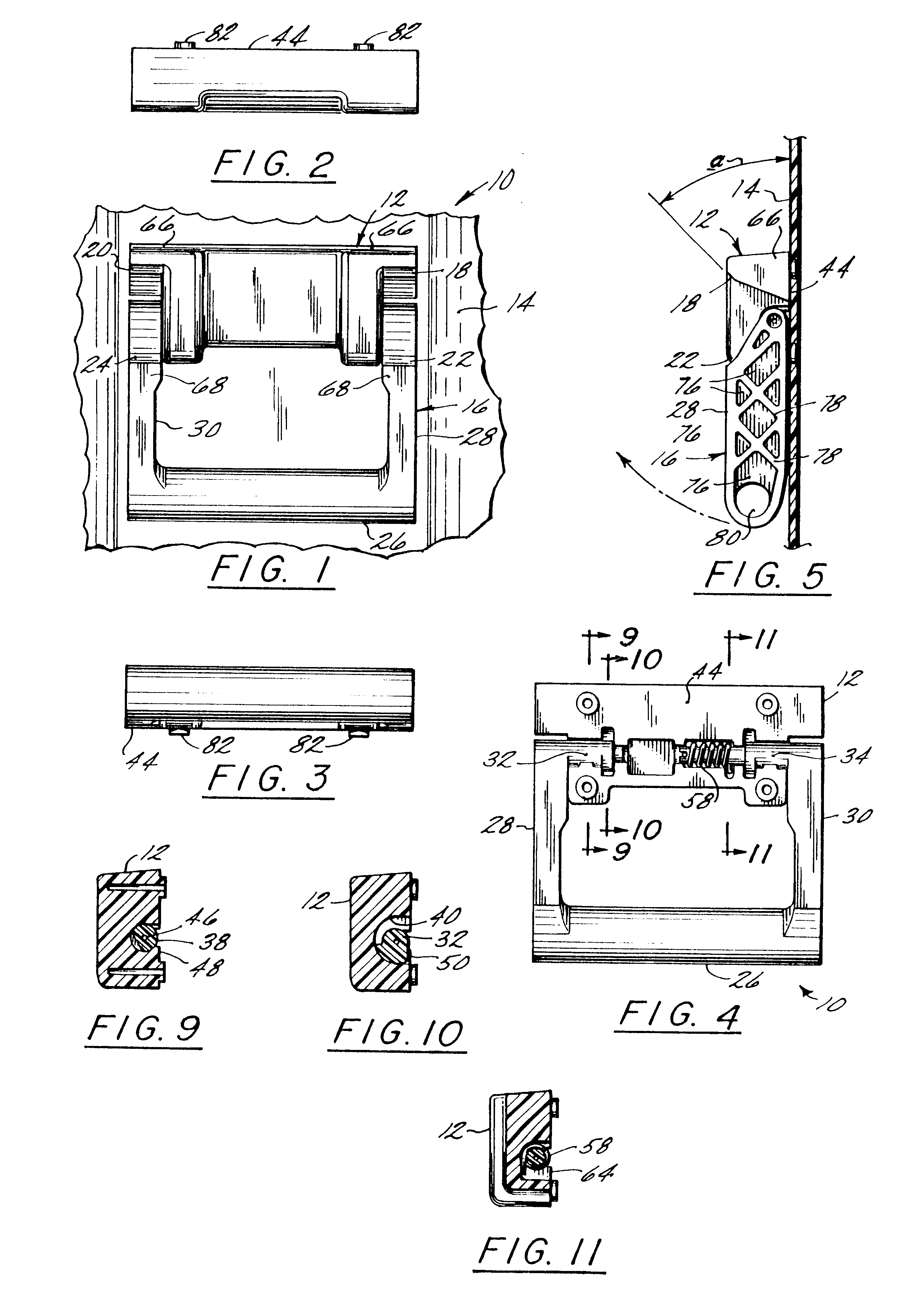

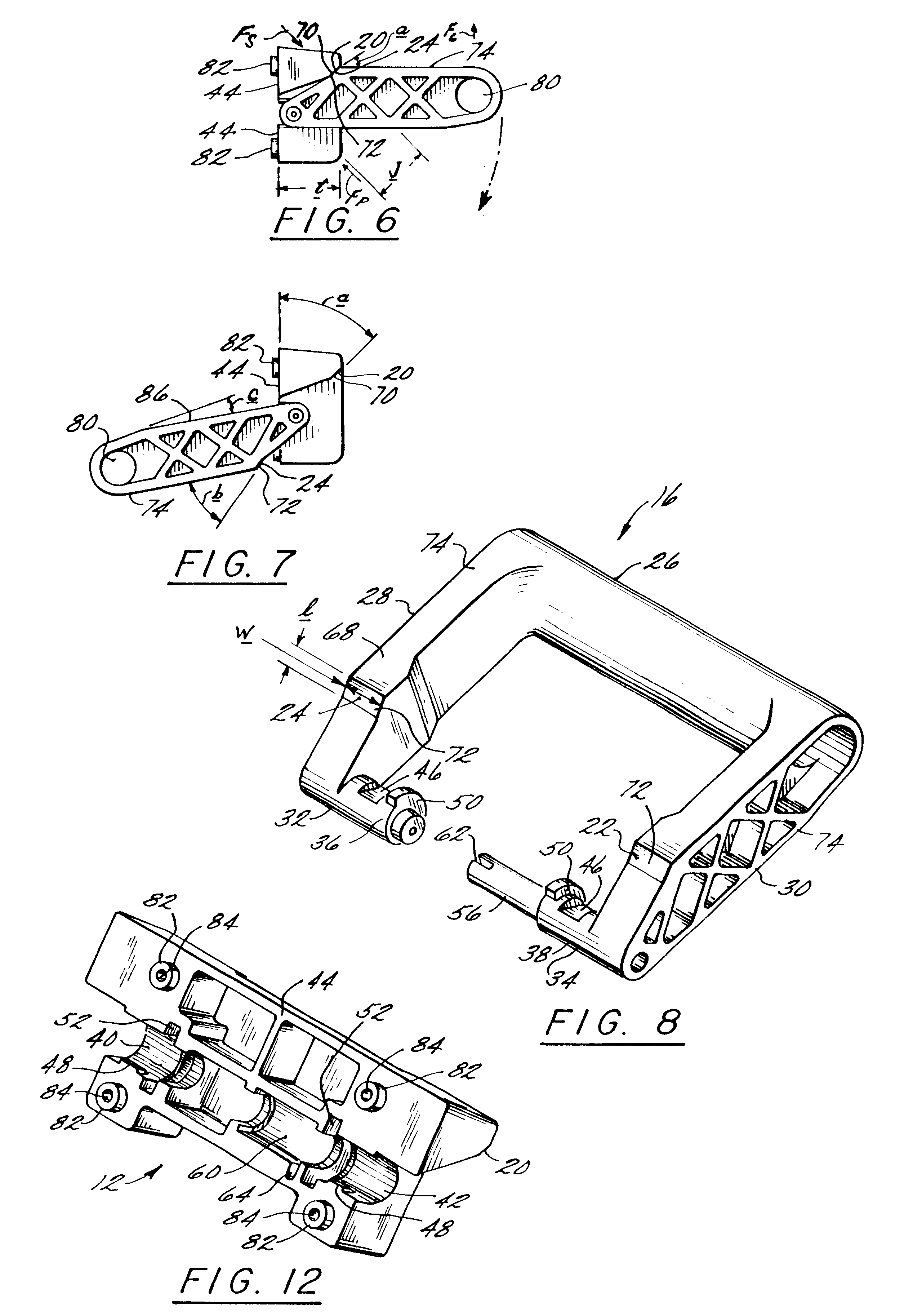

Referring to FIG. 1, the light weight handle assembly 10 according to the present invention is shown. The handle assembly 10 generally comprises a stationary bracket 12 mounted to a container wall 14 which may be a wall of a roto-molded container or any other container used to carry objects such as sensitive electronic equipment. The handle assembly 10 further comprises a movable handle 16 which is pivotally connected to the stationary bracket 12. When the stationary bracket 12 is connected to the container wall 14, the movable handle 16 may be pivoted between an inoperative position (FIG. 5) and an operative position (FIG. 6). When the stationary bracket 12 is not attached to or is removed from the container wall 14, the movable handle 16 may be pivoted to a disengaged position (FIG. 7) wherein the movable handle 16 may be easily assembled to or disassembled from the stationary bracket 12. This feature of the present invention allows the handle assembly 10 to be quickly assembled, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com