Wheel-activated vehicle restraint system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

While the invention will be described in connection with certain preferred embodiments, there is no intent to limit it to those embodiments. On the contrary, the intent is to cover all alternatives, modifications, and equivalents included within the spirit and scope of the invention as defined by the appended claims.

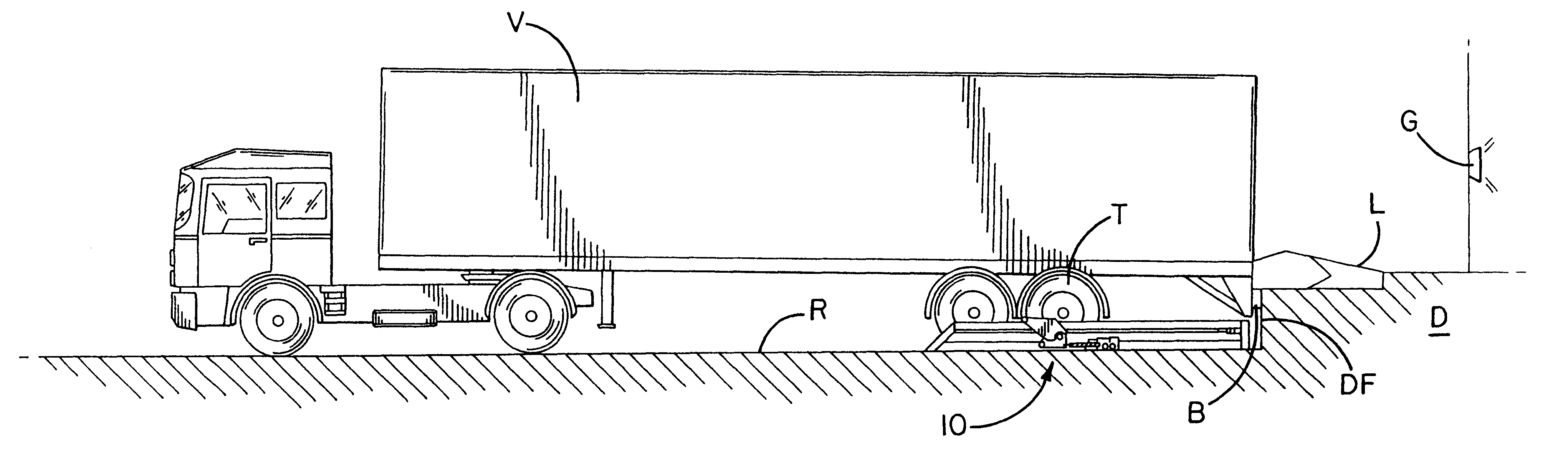

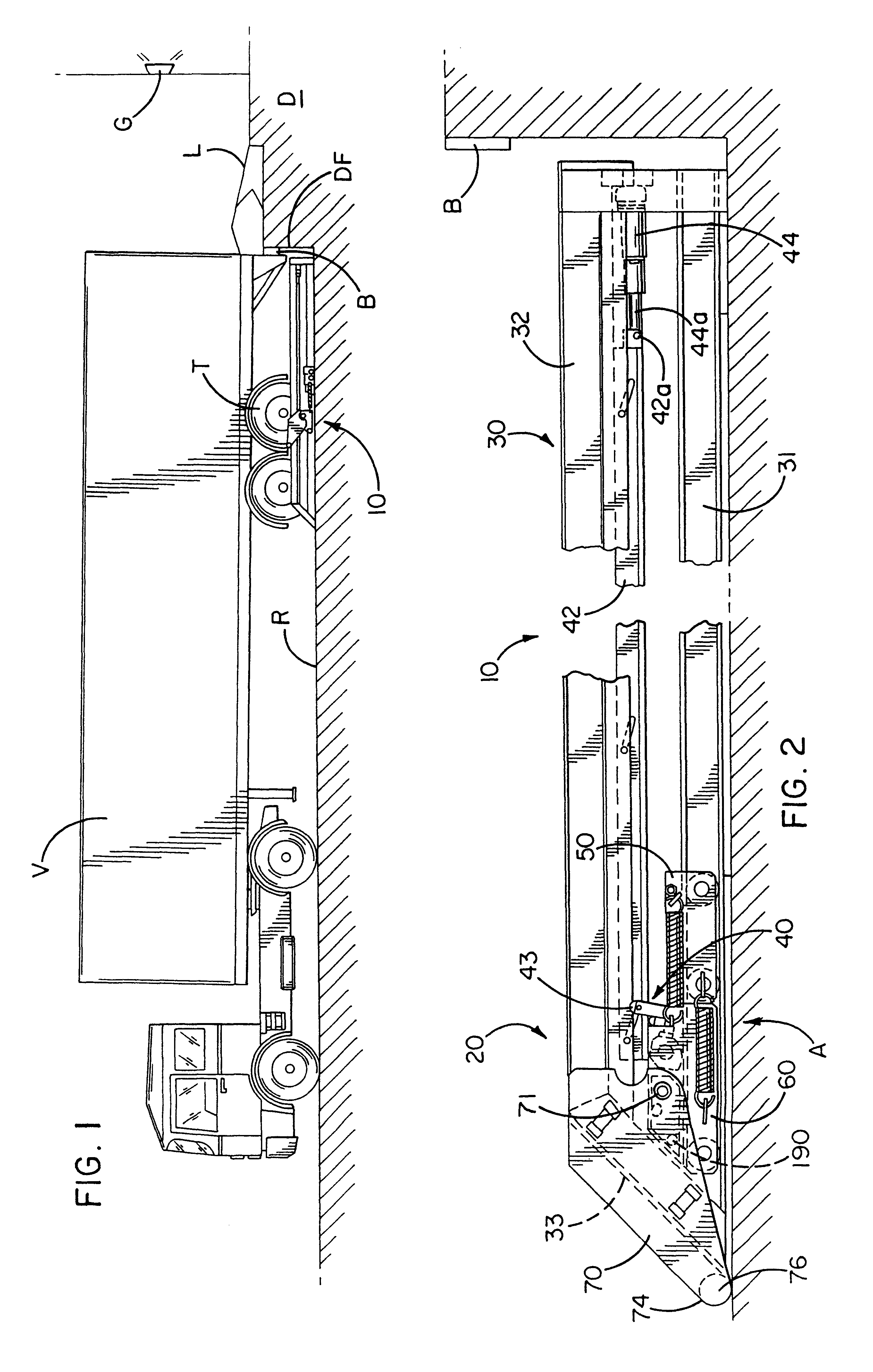

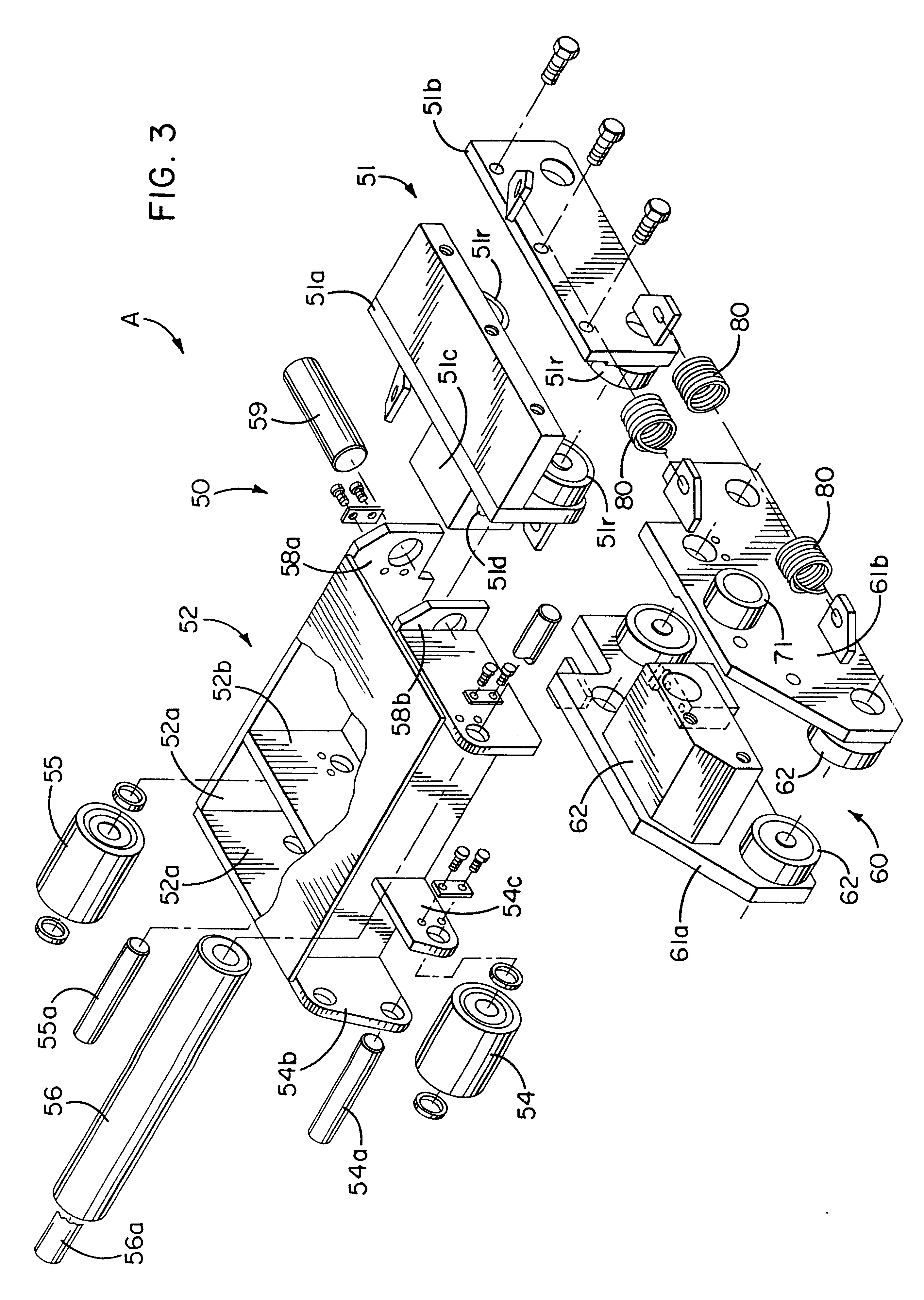

The tire-actuated vehicle restraint device according to the present invention is shown in an illustrative operating environment in FIG. 1. The restraint device 10 engages a leading tire T of a vehicle V to maintain the vehicle V in a loading / unloading position adjacent a loading dock D. The term "tire" as used herein refers to the combination of a wheel and a tire rotatably mounted to a vehicle V. Thus, an action performed on a tire is also performed on a wheel. Tire T is referred to as the "leading" tire as it is the first to approach the dock D as the vehicle V backs into position over the roadway R. As is conventional, the dock D shown in FIG. 1 includes a dock levele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com