Support or pressure roll for a paper roll winder

a technology of winding rod and paper roll, which is applied in the direction of portable power tools, applications, and ways, can solve the problems of unattractive ridge patterns on the surface of the winding rod, and achieve the effects of reducing interlayer shear stress, relative hardness, and absolute hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

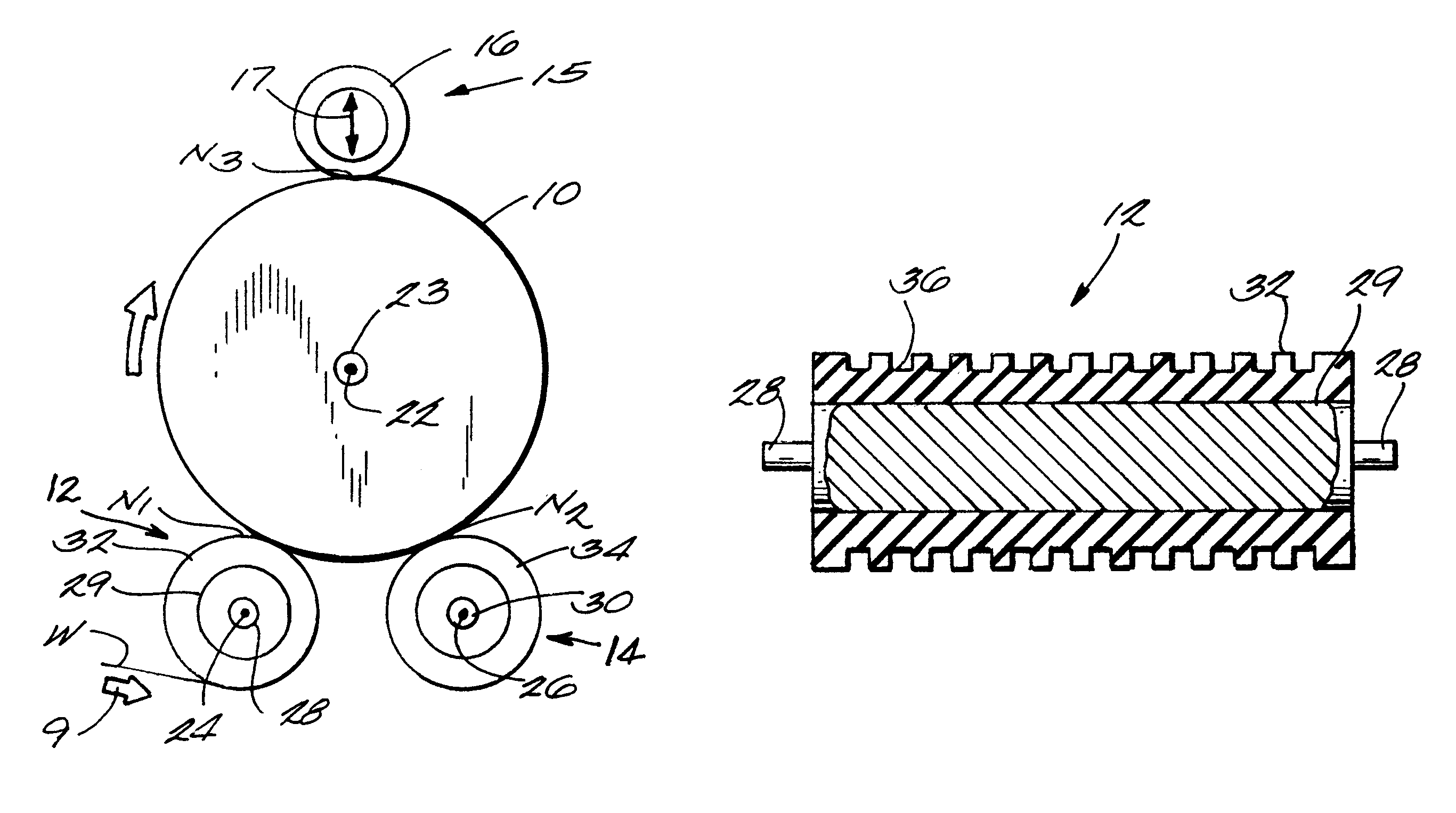

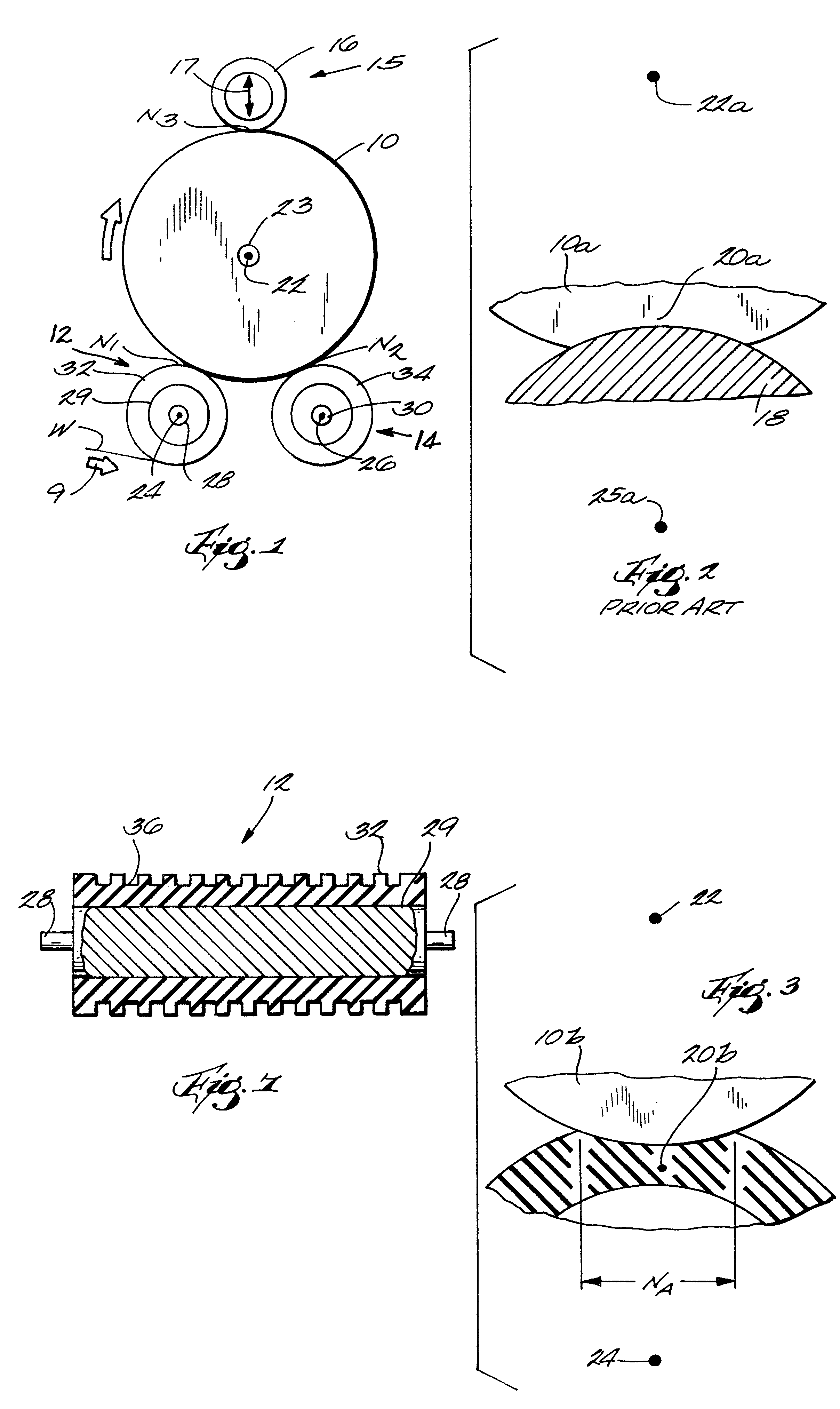

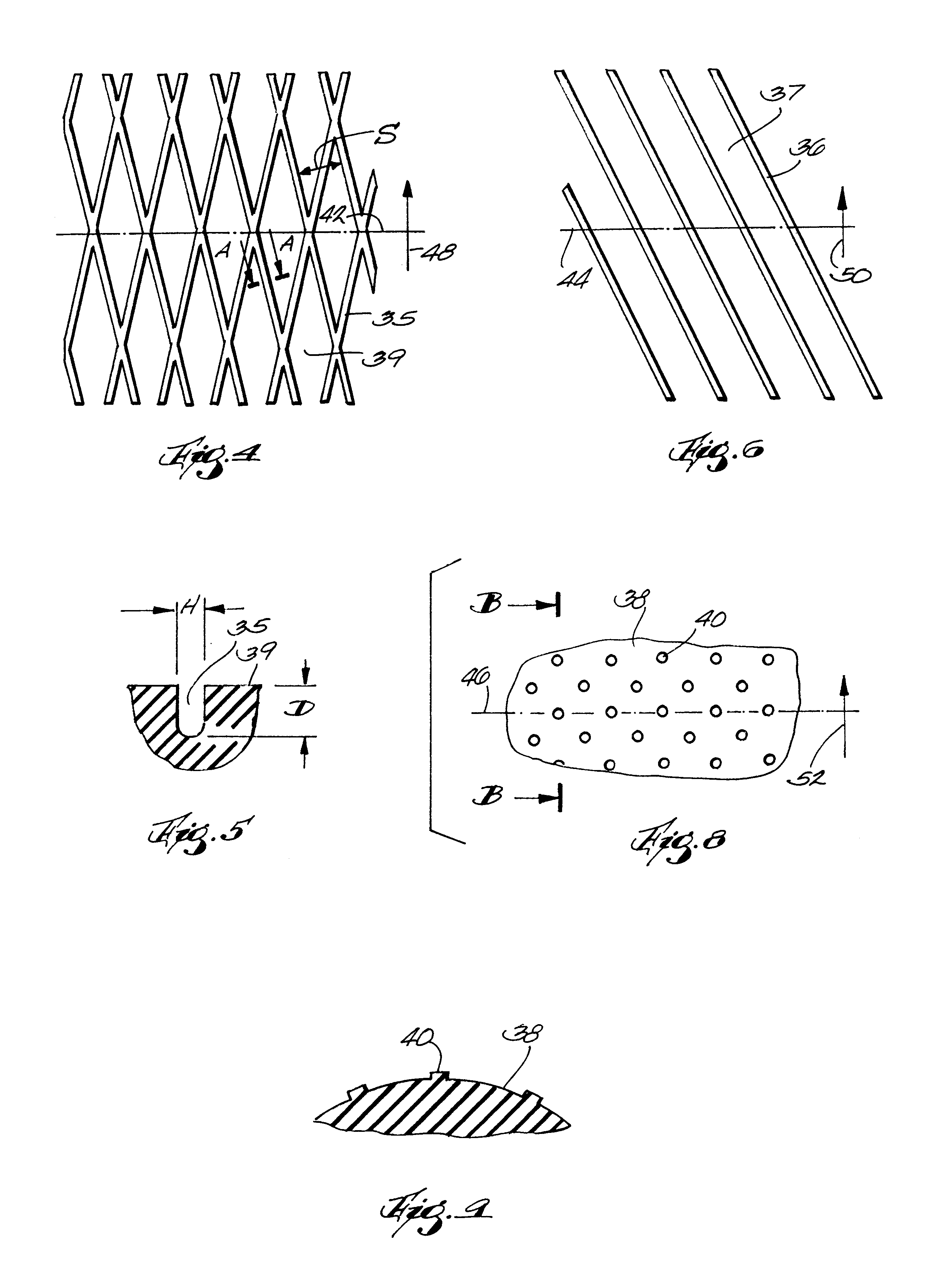

As shown in FIG. 1, a traveling paper web W, moving in the direction of arrow 9, is being wound into a wound paper roll 10 while being supported by a pair of horizontally arrayed, parallel, spaced support drums which are generally designated with the numerals 12, 14. A rider roll 15 is disposed for substantially vertical movement, indicated by arrow 17, while maintaining nipping contact at N.sub.3 with the wound paper roll. The wound paper roll is supported on the two winder support drums along their respective nip lines of contact N.sub.1,N.sub.2, respectively.

In this description, where convenient, corresponding, or similar, components will be similarly designated with different suffixes used to distinguish between them.

The wound paper roll, although relatively hard, is not as hard as, for example, a solid steel winder drum. Thus, a representation of a wound paper roll 10 having a center shaft 23 supported on an ordinary steel winder support drum 18 could be as shown in FIG. 2 wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com