Microplate assembly and closure

a microplate and assembly technology, applied in the field of sample handling and storage assembly, can solve the problems of increasing cross contamination between wells, manual labor, and many applications, and achieve the effect of quick and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The following is a description of the preferred embodiments of a microplate assembly with closure that provides for sealing and sampling a plurality of sample vials in the microplate.

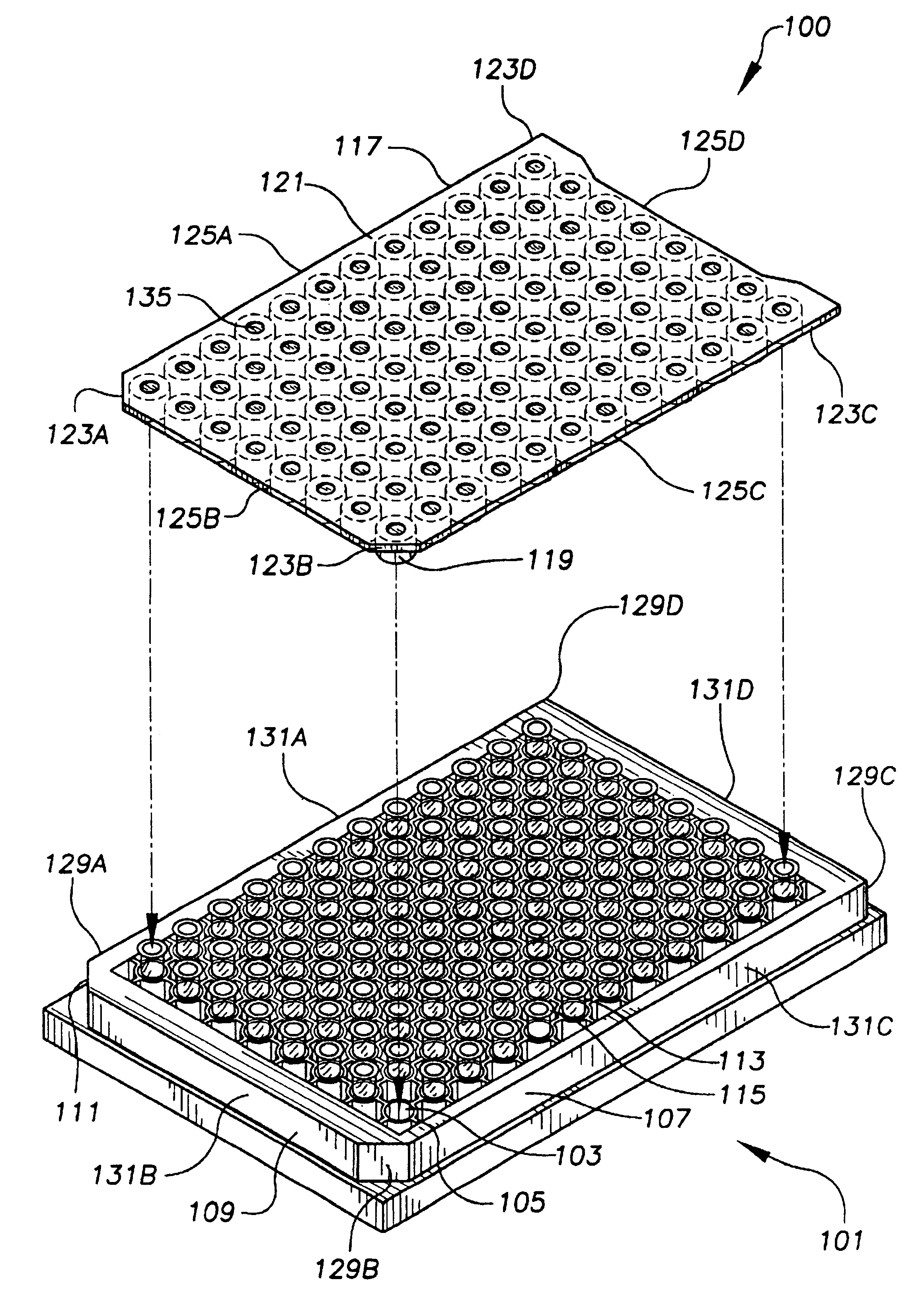

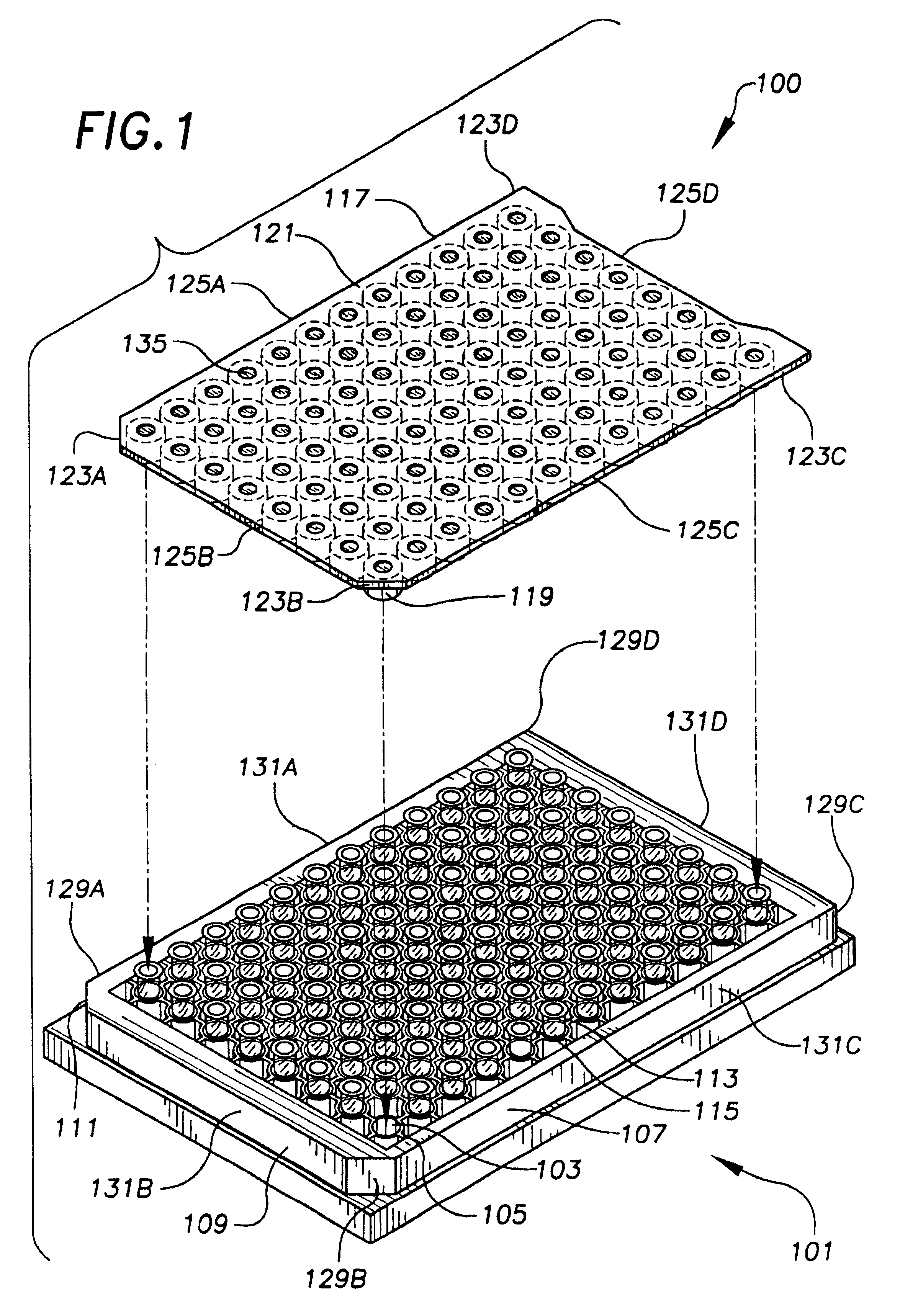

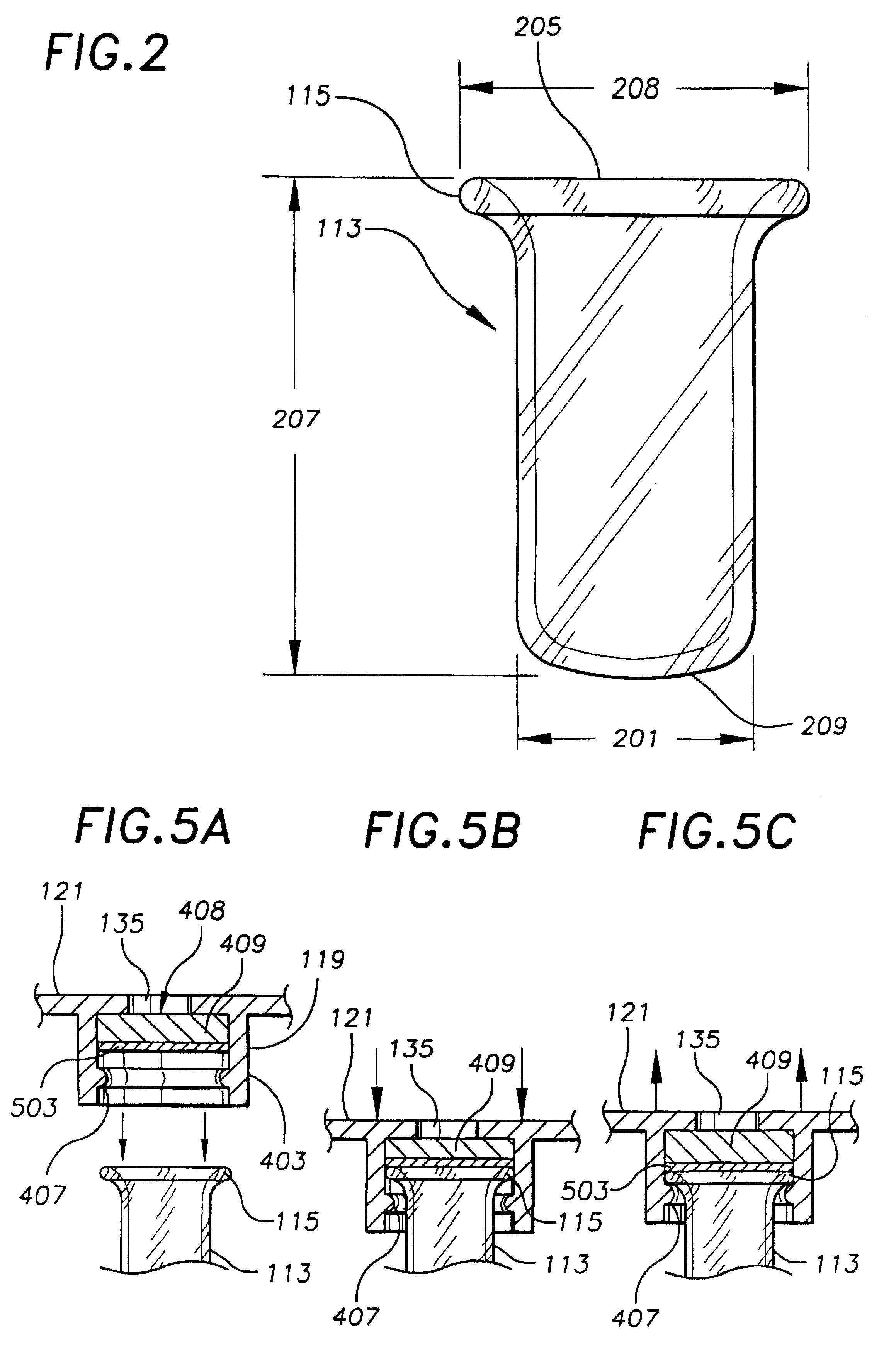

FIG. 1 is a perspective drawing of embodiment 100 of the microplate assembly with closure. Microplate 101 comprises a plurality of wells 103 arranged in a geometric pattern. In the preferred embodiment, the geometric pattern is a rectangular array eight wells in width and 12 wells in length. In the preferred embodiment, wells 103 are 6.2 millimeters in diameter (nominal dimensions) and the spacing of wells 103 in the length and width directions is 9 millimeters. In other embodiments, microplates of different numbers of wells or geometric patterns of wells are used. In the preferred embodiment, microplate 101 is made of a plastic material such as polyethylene or polypropylene. In other embodiments, microplate 101 is made of metal, composites, or glass. Microplate 101 may be machined, die cast or injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com