Movable target system in which power is inductively transformed to a target carrier

a target carrier and inductive transformation technology, applied in the direction of movable targets, target ranges, weapons, etc., can solve the problems of brush wear with use, lower voltage supplied to electric motors, and interference with the electrical connection between brushes and conductor strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

the invention may be characterized as a movable target system having a target carrier that is driven by a movable, looped cable along a track. Electrical power is transferred to the movable cable via a stationary inductor which is inductively coupled to the cable. Power induced in the cable is received by the carrier and used to power electrical equipment on board the carrier. This first embodiment of the invention will now be described.

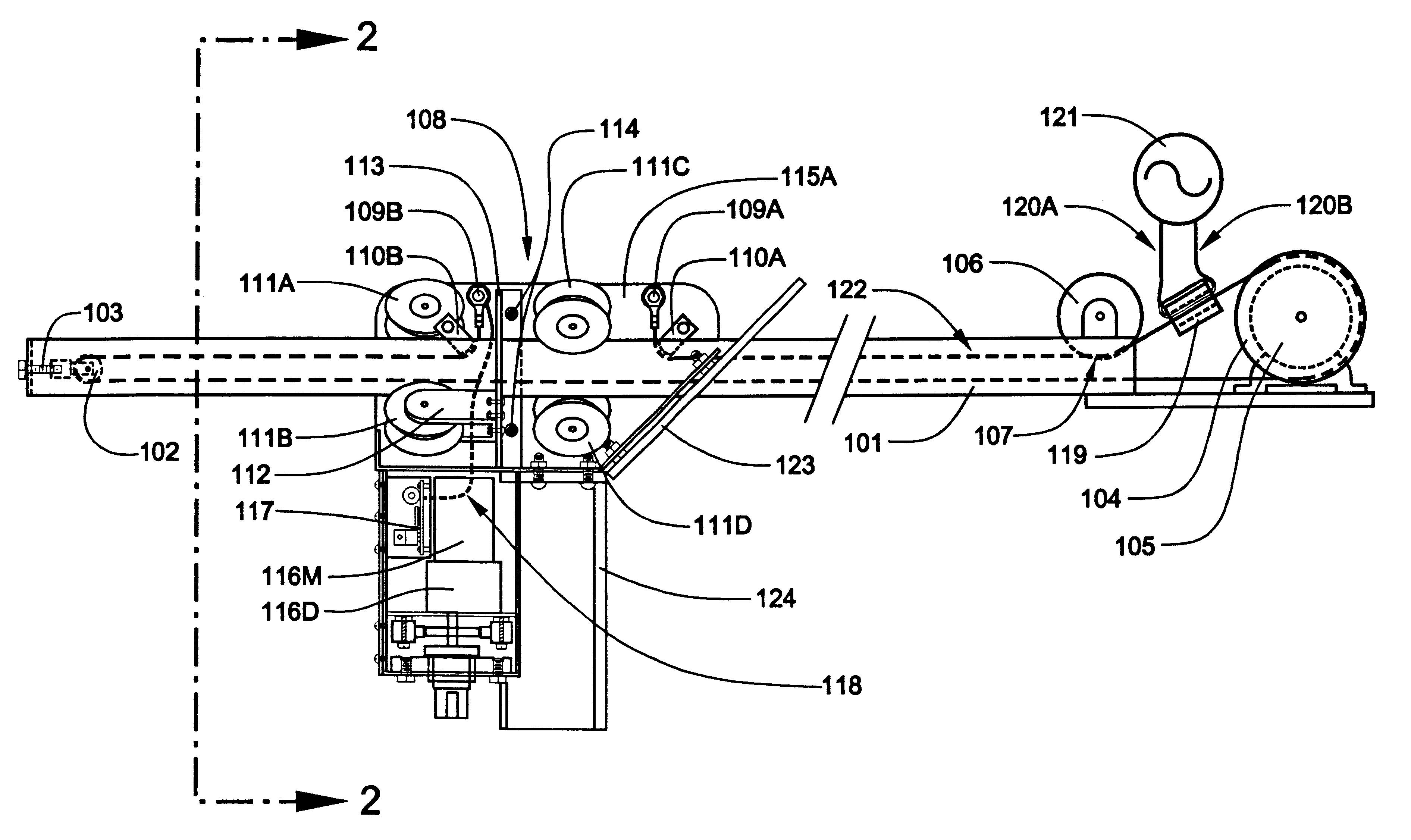

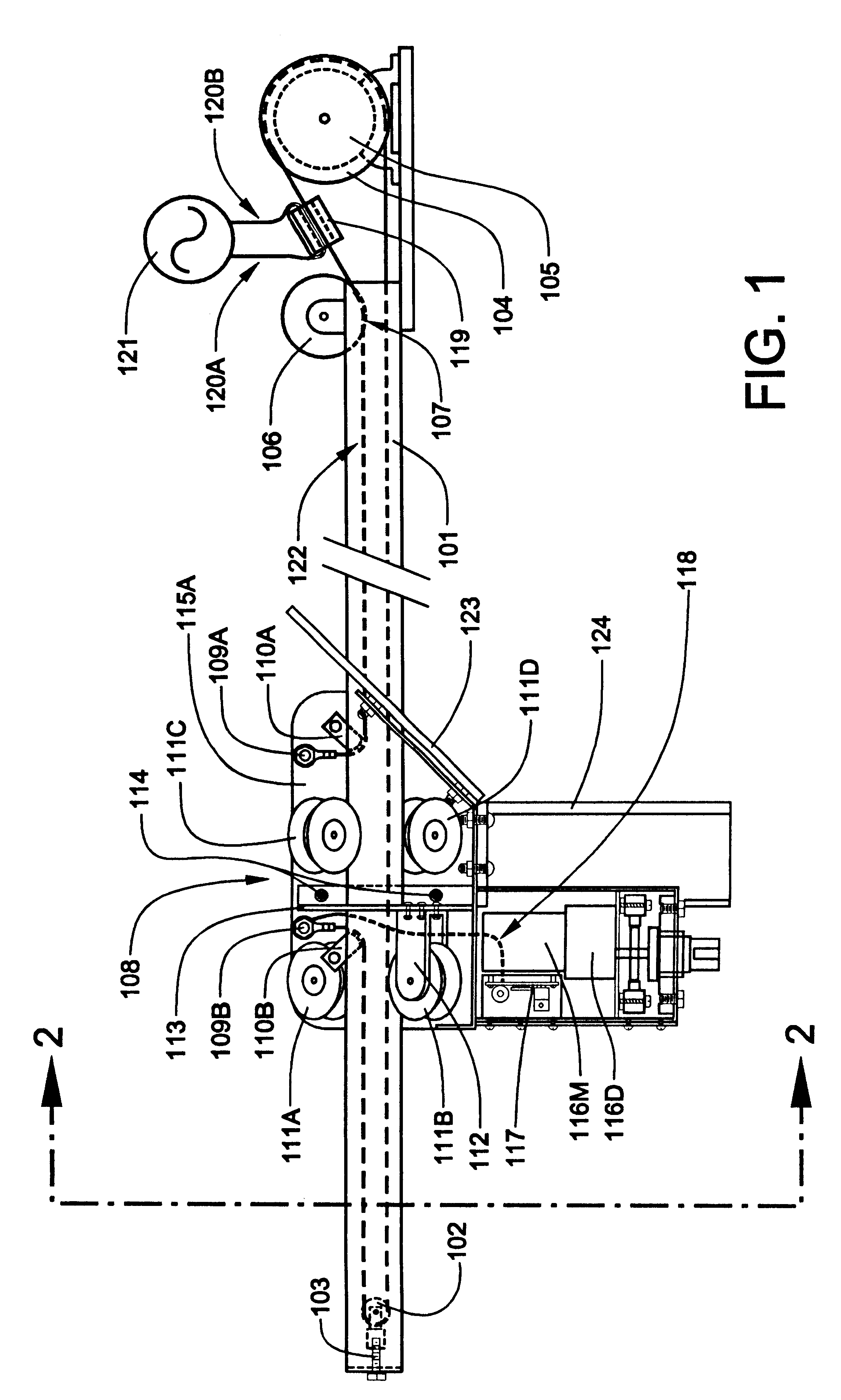

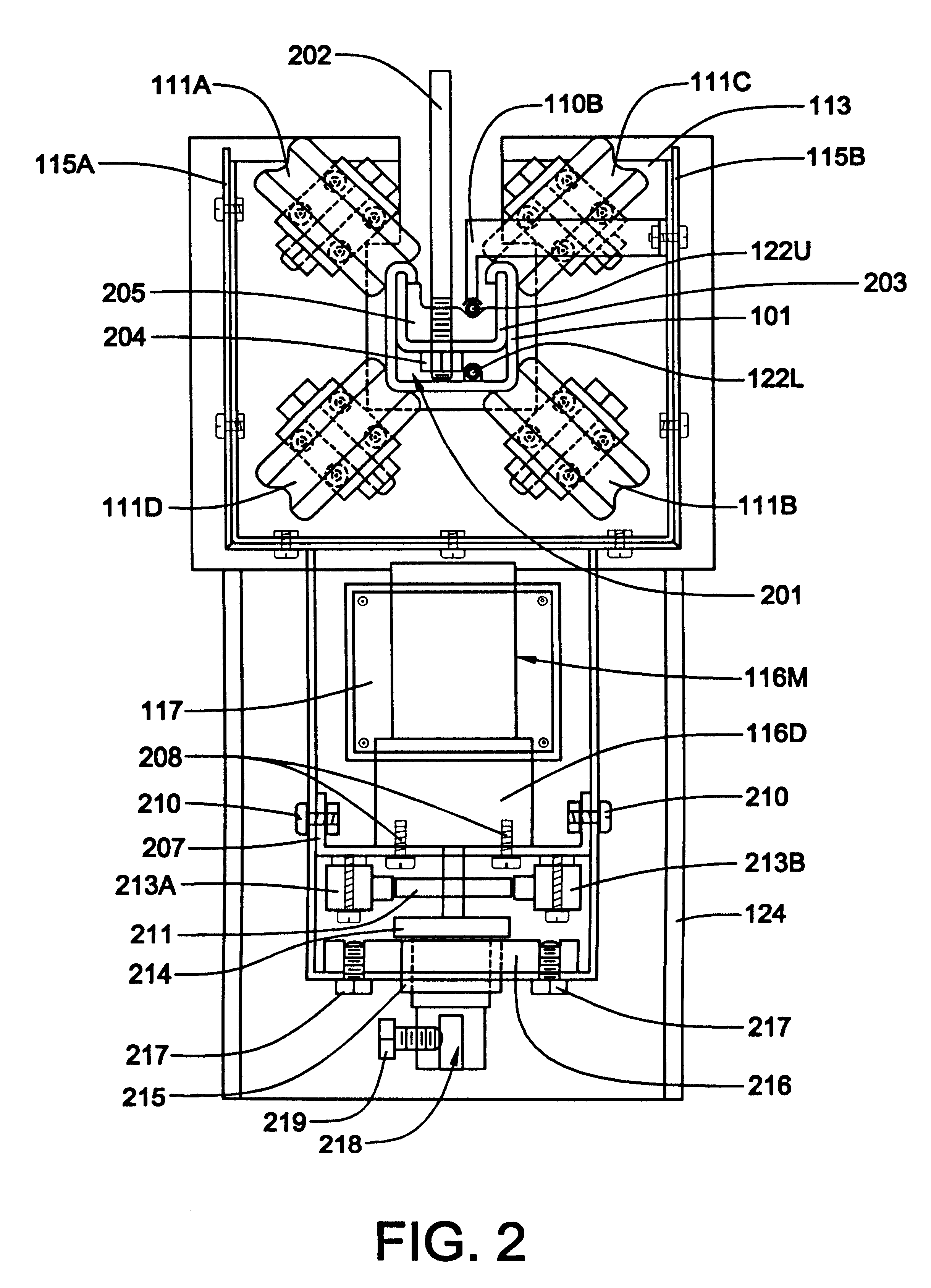

Referring now to FIG. 1, an overhead track 101 of substantially rectangular, U-shaped cross section, having an upward-facing groove or channel (see FIG. 2, item 201) that extends along the length of the track, is provided between two locations between which a target must be movably positionable. A first idler pulley 102 incorporating a tensioning device 103, is mounted within the channel 201 at a first end of the track 101. A drive pulley 104, powered by a drive motor 105, is mounted in line with the channel 201 near the opposite, or second, end of t...

second embodiment

the invention may be characterized as a movable target system having a target carrier movable along a track which encloses a stationary cable to which alternating current is applied. The carrier incorporates onboard electrical equipment that at least includes an electric transport motor. The onboard electrical equipment receives it power from an inductor which slides along the stationary cable. This second embodiment of the invention will now be described.

Referring now to FIG. 4, a conductive overhead track 401 of substantially rectangular, U-shaped cross section, having an upward-facing groove or channel (see FIG. 5, item 501) that extends along the length of the track, is provided between two locations between which a target must be movably positionable. A first cable anchoring device 403A incorporating a cable tensioner 404 is longitudinally aligned with and positioned at one end of the track 401, being electrically connected thereto. An alternating current source 405, having fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com