Simulated wave water sculpture

a technology of water sculpture and simulation wave, which is applied in the field of simulation wave water sculpture, can solve the problems of inability to create realistic-looking wave-like shapes or wave-forms, inability to simulate natural propagating wave, and inability to create deep water propagation for many such sculptures, etc., and achieves visual, aural and/or aesthetic appeal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Basic Sheet Flow

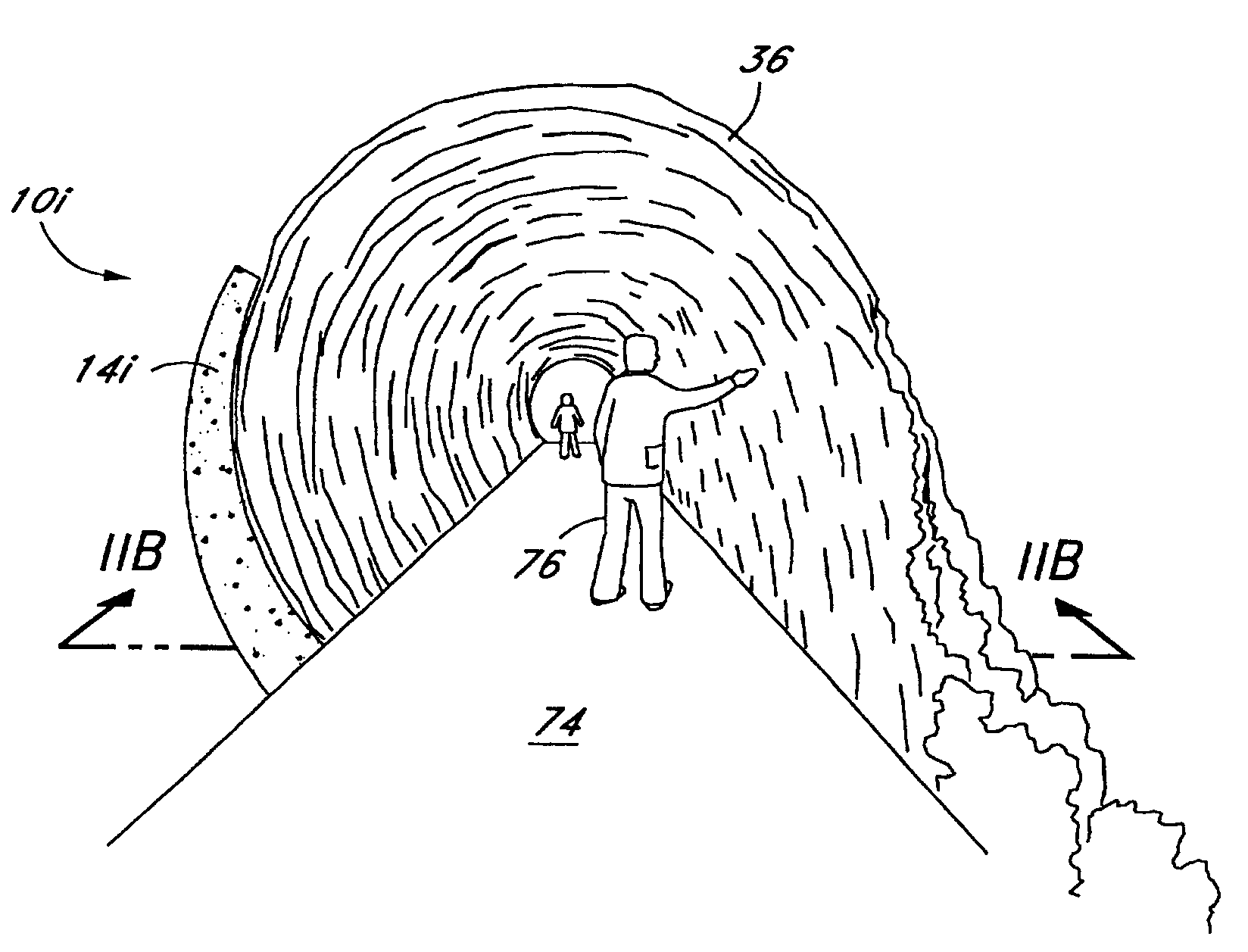

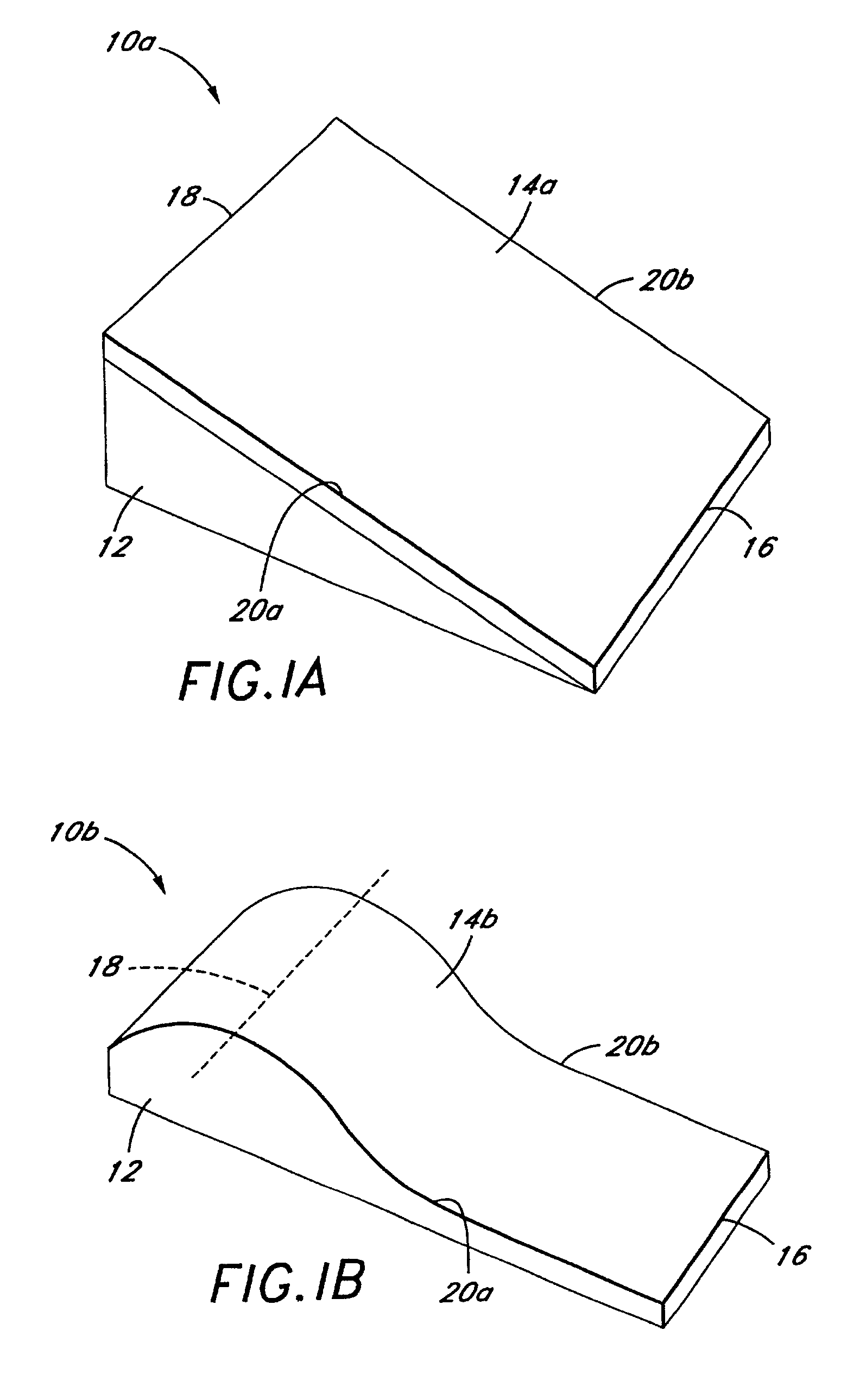

[0053]FIG. 1A shows one embodiment of a simple water sculpture 10a having features of the present invention. Sectional lines as revealed in FIG. 1A are solely for the purpose of indicating the three-dimensional shape in general, and are not illustrative of a specific frame, plan, or profile sections. Rather, it should be noted that a wide variety of dimensions and configurations for the water sculpture 10a are compatible with the principles and teachings of the present invention. Therefore, these principles and teachings should not be construed to be limited to any particular configuration illustrated in the drawings or described herein.

[0054]The water sculpture 10a generally comprises a subsurface structural support 12 and a flow surface 14a, defined by upstream edge 16, downstream edge 18, and side edges 20a and 20b. The flow surface 14a is preferably smooth and can be a skin placed over the sub-surface structural support 12, or the structures can be integrated tog...

example 2

Simulated White Water Bore

[0058]FIG. 3 illustrates a water sculpture 10 with a flow profile that simulates a stationary white water bore. When the velocity (i.e., kinetic energy) of an upwardly inclined supercritical sheet flow 24, moving in direction 26, is less than the gravitational potential energy downstream of the upper edge or ridge line 18, then sheet flow 24 will form a hydraulic jump 28 prior to reaching downstream ridge line 18. Accordingly, white water 30 will roll downward and to the side as run-off water 32, and, an effect similar to a stationary white water bore will form on the flow surface 14a. Maintenance of this hydraulic state requires that the kinetic energy of supercritical flow 24 always be less than the potential energy at the downstream edge or ridge line 18. The relative position of the hydraulic jump 28 will be determined by the velocity of the supercritical flow 24. The higher the velocity, the higher the position of the hydraulic jump 28 upon flow surfac...

example 3

Simulated Spilling Wave

[0059]A simulated spilling wave with a smooth unbroken shoulder may be created on a flow surface by two general methods: (1) a cross-stream velocity gradient and (2) a cross-stream pressure gradient. The use of either method depends upon overall objectives and constraints of the flow surface structure and available flow characteristics. A cross-stream velocity gradient is the preferred method when the structure of the flow surface is limited to a symmetrical configuration such as flow surface 14a shown in FIG. 4A. A cross-stream pressure gradient is the preferred method when the initial supercritical flow 24 moving up the flow surface has constant velocity such as shown in FIG. 4B.

[0060]FIG. 4A depicts one preferred method for producing a simulated spilling wave with a smooth unbroken shoulder. This wave is created by introducing a cross-stream velocity gradient to a supercritical flow of water that moves in direction 26 up the flow surface 14a with a level ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com