Electronic watch

a technology of electronic watch and stepping motor, applied in the direction of generating/distributing signals, dynamo-electric converter control, horology, etc., can solve the problems of magnetic interference with the other stepping motor, particularly and difficult to achieve normal operation at a low voltag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138]Examples of an electronic watch according to the present invention will be described in detail below, with reference being made to the appropriate accompanying drawings.

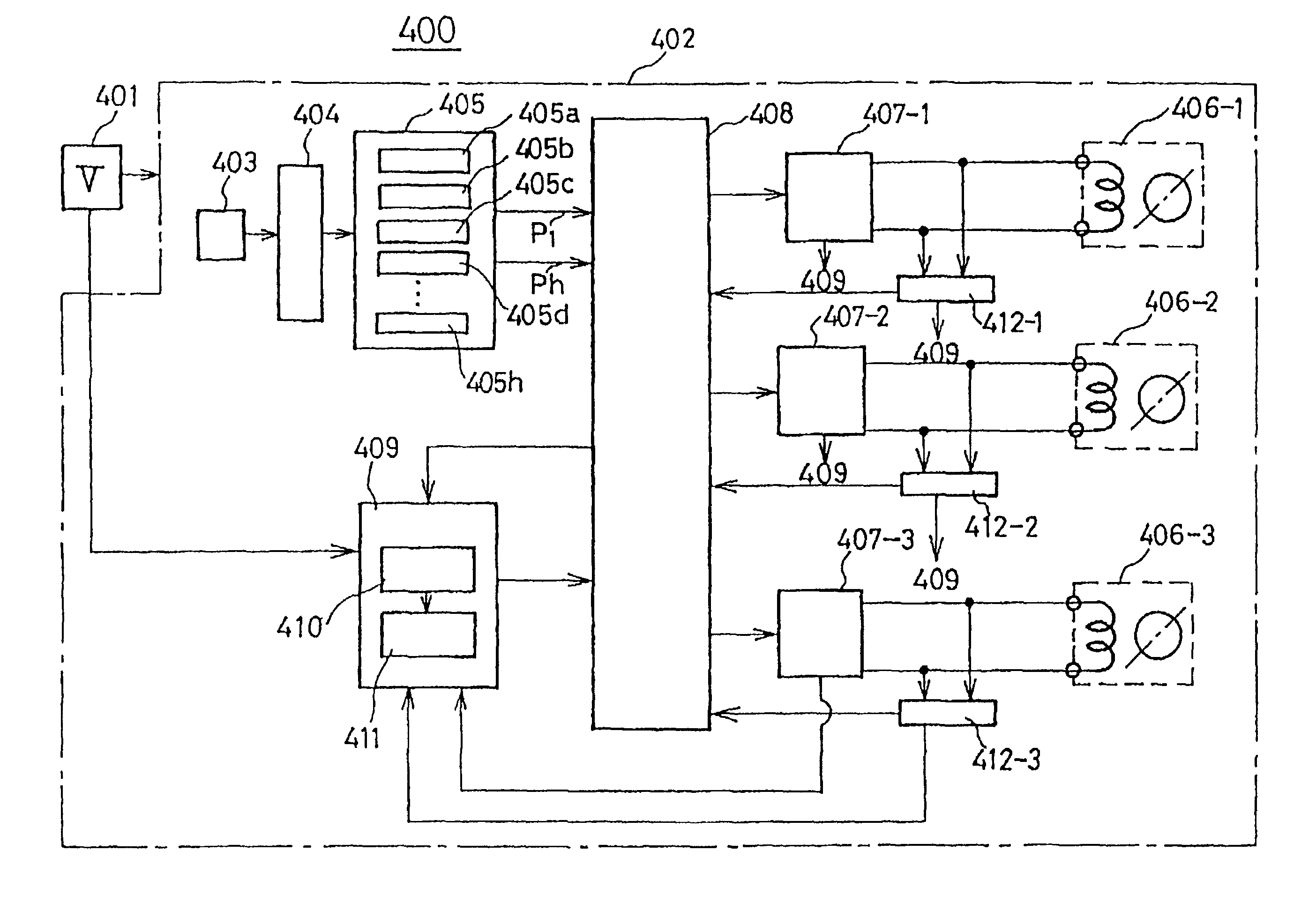

[0139]FIG. 9 is a block diagram which shows in simplified form an example of the configuration of an electronic watch 400 according to the present invention. In this drawing, the electronic watch comprises a power supply 401 and a watch circuit 402. The watch circuit 402 comprises an oscillator circuit 403, a frequency divider circuit 404, a drive pulse generation means 405, a drive motor 406 which, in response to a drive pulse P1 that is output by the above-noted drive pulse generation means 405, drives at least one of the hour / minute, second, and functional hands including chronograph hands, a drive circuit means 407 which controls the drive of the drive motor 406, a drive circuit control means 408 which controls the above-noted drive circuit means 407, and a control condition detection means 409 which is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com