300 mm microenvironment pod with door on side

a microenvironment pod and door technology, applied in the field of packaging, can solve the problems of only compounding problems, difficult to design a suitable package, and high cost of suitable packaging for use in connection with storage and transportation of wafers, and achieve the effects of high efficiency, easy cleaning, and reusable packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

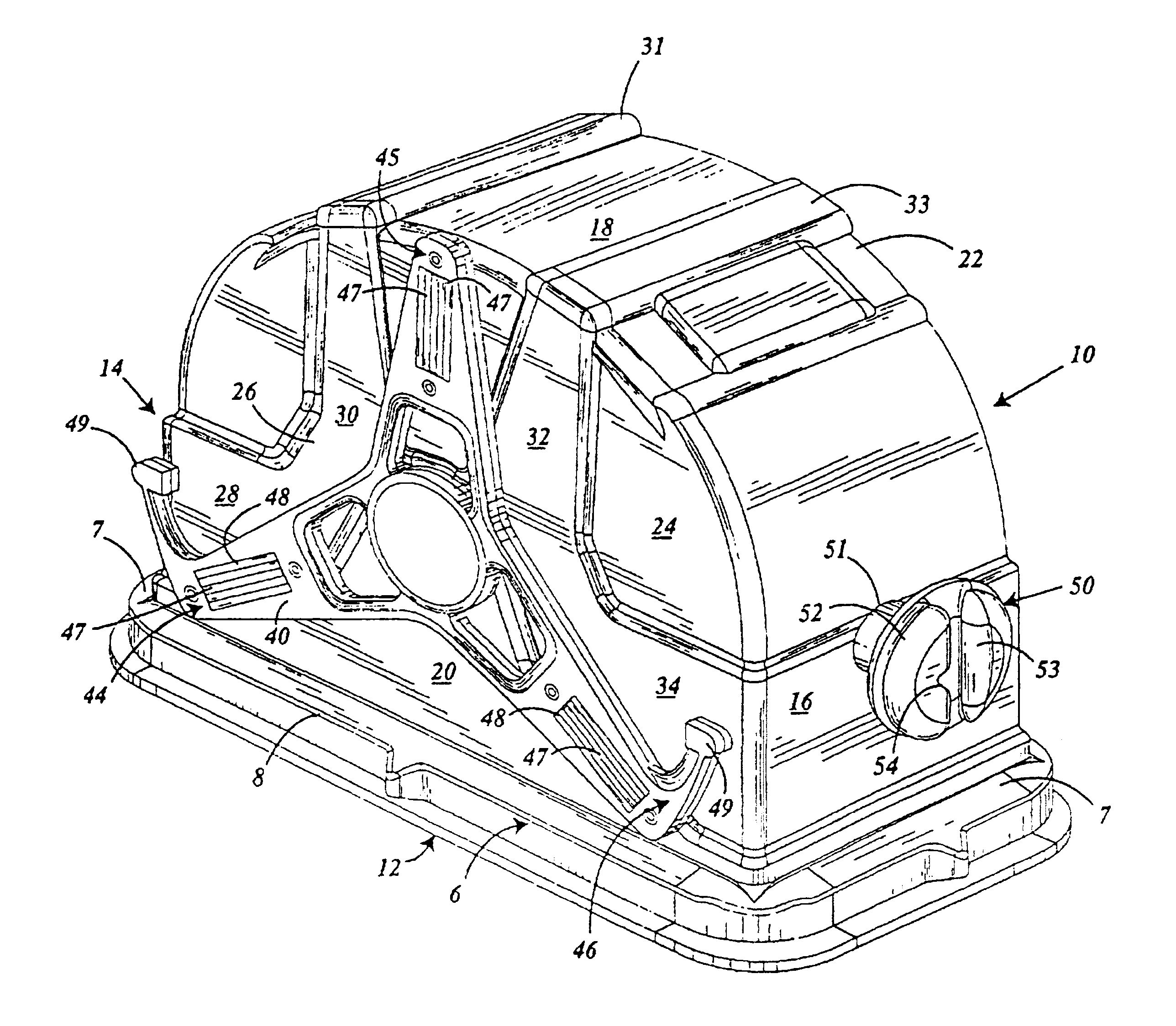

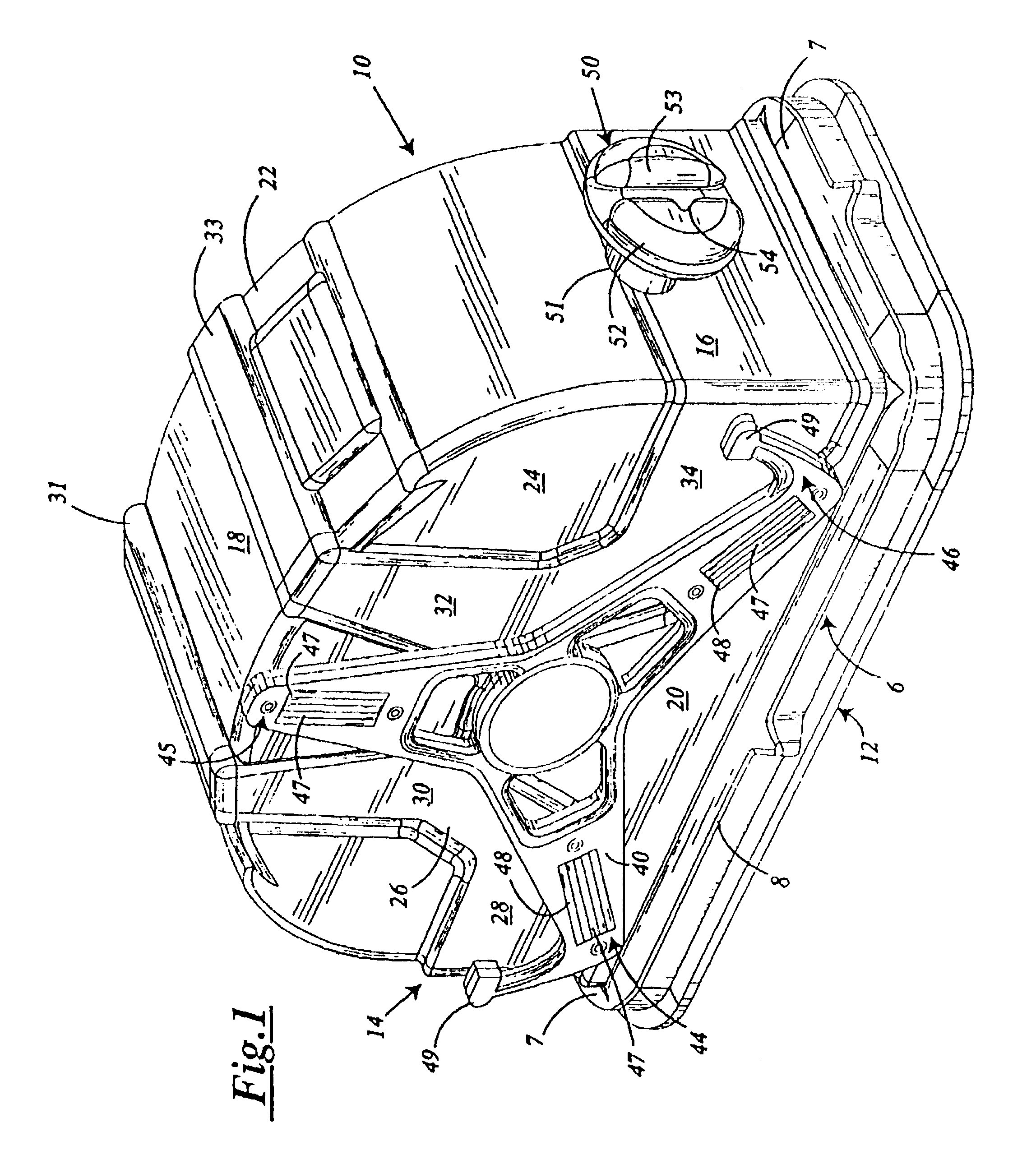

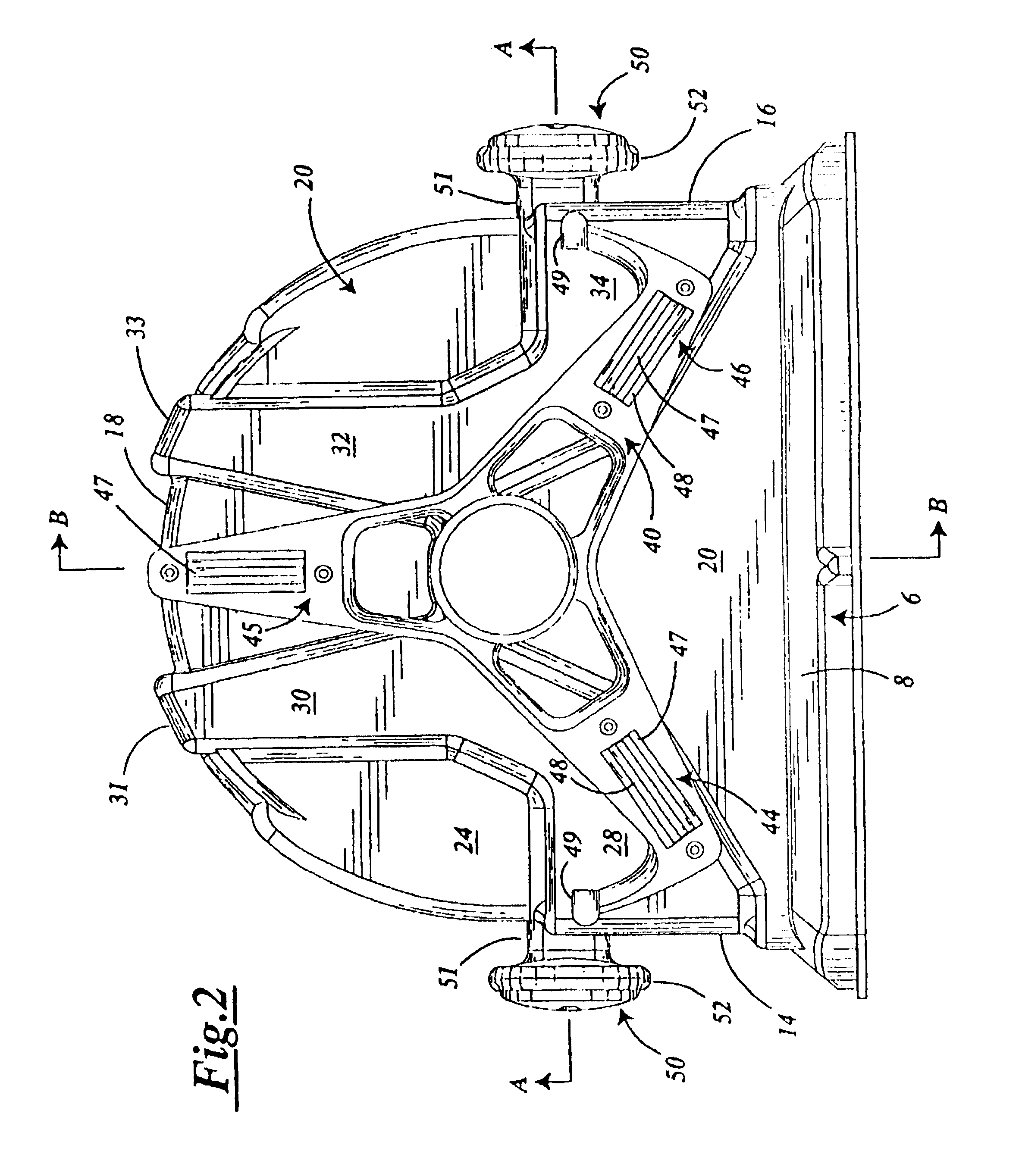

[0037]As shown in FIG. 1, the container of the present invention has an exterior shell 10. The exterior shell 10 has six sides 12, 14, 16, 18, 20 and 22.

[0038]Side 12 comprises a door frame 6 having a pair of opposing end portions 7 and a pair of side portions 8. Sides 14 and 16 of the exterior shell 10 are defined generally by straight walls extending from the opposite end portions 7 of the door frame 6. Wall 18 extends between walls 14 and 16 and is in the shape of a partial cylinder. The radius of curvature of wall 18 is generally the same as the radius of curvature of the wafer to be stored in the container. Top and bottom walls 20 and 22 complete the shell. Walls 20 and 22 have a generally flat surface 24 and a reinforcement member 26 projecting outwardly from the flat surface 24. Reinforcement member 26 prevents warpage of the container and especially walls 20 and 22. Reinforcement members 26 have four legs 28, 30, 32 and 34. Extending across wall 18 between the two legs 30 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical charge | aaaaa | aaaaa |

| electrical path | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com