Flexible material

a flexible material and manufacturing method technology, applied in the field of flexible material manufacturing, can solve the problems of restricting limiting the movement of wearers, and expensive or inconvenient supply of different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

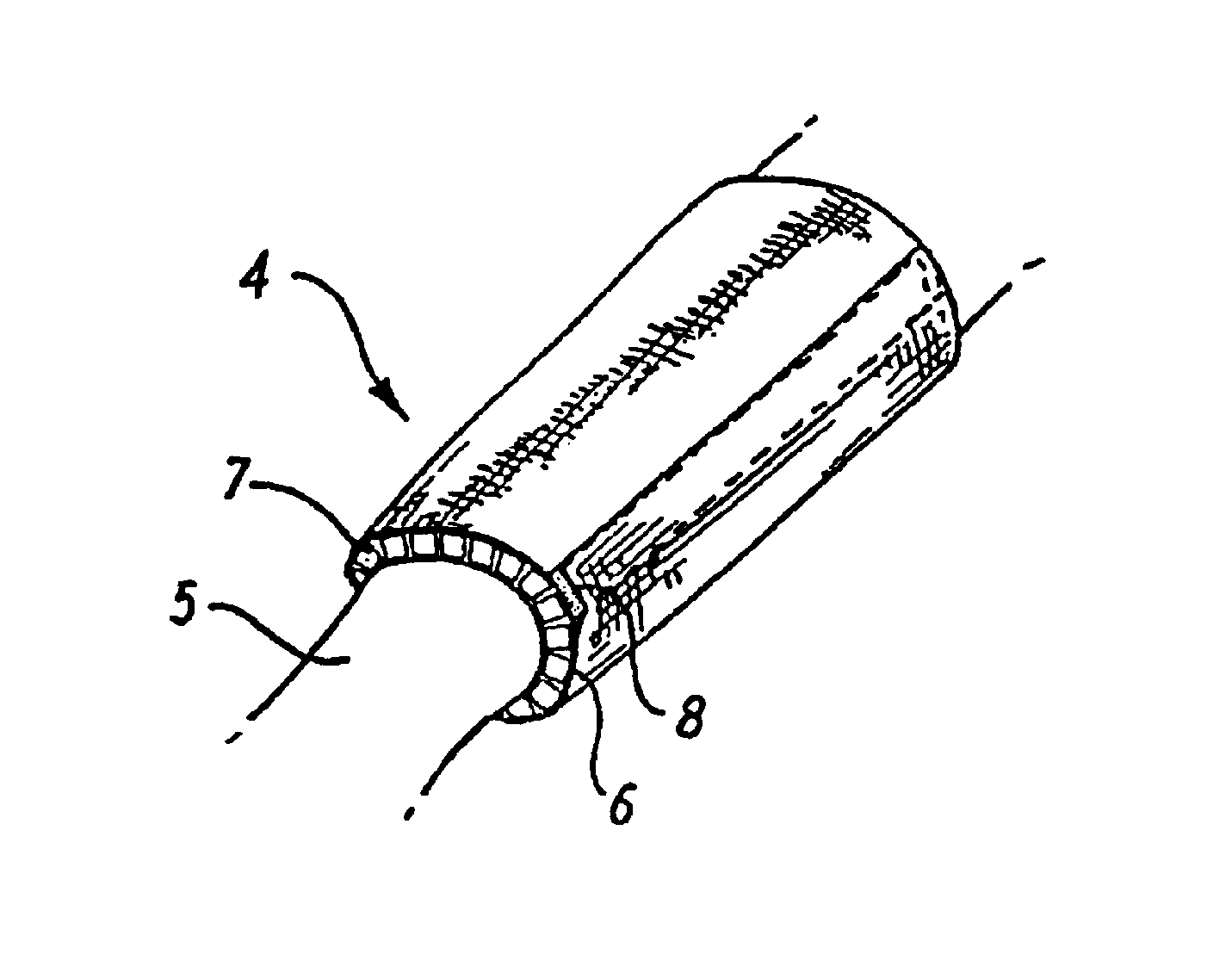

[0040]Referring to FIG. 1, a flexible material comprises a plurality of cubes 1 of a resilient closed-cell polyethylene foam, of side approximately 12 mm and with corners of radius approximately 2.5 mm, joined with a hot melt adhesive to a fabric substrate 2. The cubes 1 are evenly arranged, each cube being spaced from adjacent cubes by approximately 2 mm. The fabric 2 is a resiliently stretchable knitted fabric, preferably one comprising polyester or elastane fibers.

[0041]A margin of fabric 2 is provided around the periphery of the cubes 1. Along the edges of the fabric at opposite ends respectively there are strips 3 of VELCRO(™), only one of which is shown.

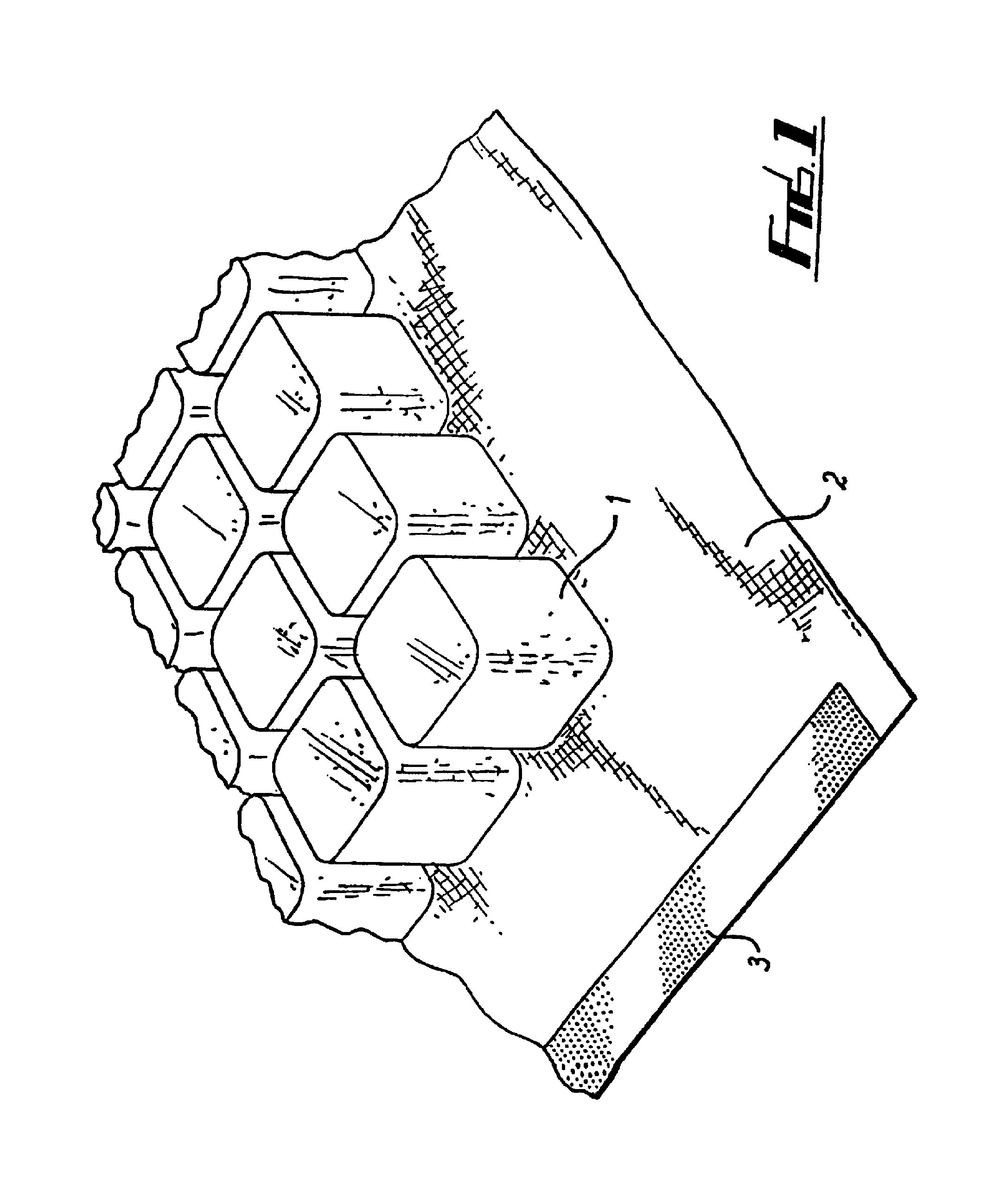

[0042]Referring to FIG. 2, a protective armband 4 is shown being worn on part of an arm 5. The armband 4 is formed from a generally rectangular piece of material of the type shown in FIG. 1 but which in this case comprises a fabric substrate 6 bonded to both sides thereof with a plurality of foam cubes 7 sandwiched therebetween...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com