Patents

Literature

60results about How to "Meet the technical needs of microwave multilayer devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

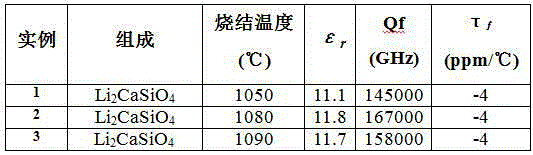

Ultralow-dielectric-constant temperature-stable microwave dielectric ceramic Li2CaSiO4

The invention discloses ultralow-dielectric-constant temperature-stable microwave dielectric ceramic Li2CaSiO4 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and mixing initial powder of Li2CO3, CaO and SiO2 of which the purity is above 99.9% (in percentage by weight) according to the constitution of the Li2CaSiO4; (2) performing wet-type ball milling and mixing on the raw materials obtained in the step (1) for 12 hours by using a ball milling medium of distilled water, drying and pre-roasting at the temperature of 1000 DEG C for 6 hours in air atmosphere; and (3) adding an adhesive into the powder prepared in the step (2), granulating and then performing press-molding, and finally sintering at the temperature of 1050 to 1090 DEG C for 4 hours in the air atmosphere, wherein the adhesive is a polyvinyl alcohol solution of which the mass concentration is 5%; the added amount of polyvinyl alcohol takes up 3% of the total mass of the powder. The ceramic prepared by the method disclosed by the invention is well sintered at the temperature of 1050 to 1090 DEG C, as high as 11.1 to 11.8 in dielectric constant, as high as 145000Hz to 167000Hz in quality factor Qf value, small in temperature coefficient of resonance frequency and extremely large in application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-quality factor ultralow-dielectric constant microwave dielectric ceramic Li2Mg2V8O23

The invention discloses a high-quality factor temperature-stabilizing ultralow-dielectric constant microwave dielectric ceramic Li2Mg2V8O23 capable of being sintered at low temperatures as well as a preparation method thereof. The preparation method comprises the following steps: (1) weighing and proportioning original powder of Li2CO3, MgO and V2O5 with the purity over 99.9wt% according to composition of Li2Mg2V8O23; (2) wet-bal-milling and mixing the raw materials in the step (1) for 12 hours, wherein a ball-milling medium is distilled water, and drying and pre-sintering for 6 hours in an air atmosphere of 750 DEG C; (3) adding an adhesive into the powder prepared in the step (2) and granulating, then pressing and moulding, an finally sintering for 4 hours in an air atmosphere at 800-850 DEG C, wherein the adhesive is a 5% (mass concentration) polyvinyl alcohol solution and the additive amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic disclosed by the invention is well sintered at 850 DEG C, the dielectric constant reaches 17.4-17.9, the quality factor Of value reaches up to 110000-141000 GHz, and the temperature coefficient of resonance frequency is small. The ceramic has a huge industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

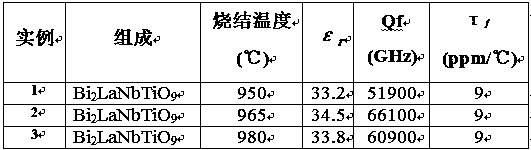

Temperature-stable low-dielectric-constant microwave dielectric ceramic Bi2LaNbTiO9 and preparation method thereof

The invention discloses temperature-stable low-dielectric-constant microwave dielectric ceramic Bi2LaNbTiO9 and a preparation method thereof. Firstly, chemical raw materials of Bi2O3, La2O3, Nb2O5 and TiO2 powder are weighed and matched according to the stoichiometric equation of Bi2LaNbTiO9; secondly, the raw materials in the first step are mixed for 12 h in a wet ball mill, ball-milling media are distilled water, and pre-sintering is performed in a 900 DEG C atmosphere for 6 h after drying; thirdly, an adhesion agent is added in the powder prepared in the second step, compression molding is performed after pelletizing, and finally, sintering is performed in a 950-980 DEG C atmosphere for 4 h; the adhesion agent is prepared from a polyvinyl alcohol solution with the mass concentration being 5%, and the adding amount of polyvinyl alcohol accounts for 3% of total mass of the powder. The prepared ceramic is good in sintering performance at the temperature of 1000 DEG C, the dielectric constant reaches 33.2-34.5, the quality factor Qf of the ceramic reaches as high as 51900-66100 GHz, the resonance frequency temperature coefficient is small, and the ceramic has great industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

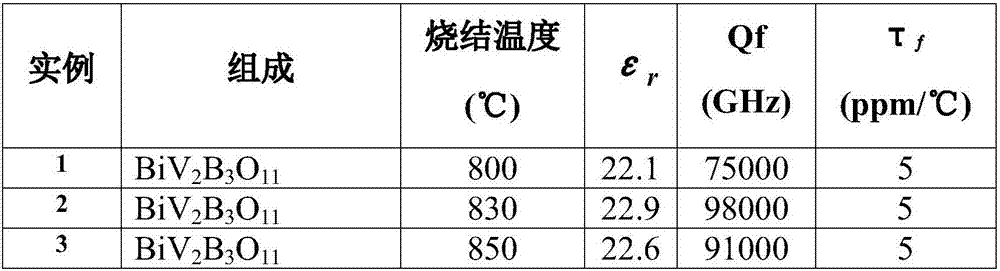

Bismuth-containing borate microwave dielectric ceramic with ultra-low dielectric constant

The invention discloses bismuth-containing borate microwave dielectric ceramic BiV2B3O11 with an ultra-low dielectric constant and a preparation method thereof. The method comprises the following steps: (1) weighing initial powder of Bi2O3, V2O5 and B2O3 having the purity of over 99.9 percent by weight according to the composition of BiV2B3O11; (2) mixing the raw materials in the step (1) by a wet ball mill for 12 hours by taking distilled water as a ball mill medium, drying, and preburning for 6 hours at an atmosphere of 750 DEG C; (3) adding an adhesive into the powder prepared in the step (2), granulating, pressing and molding, and sintering for 4 hours at atmosphere of 800-850 DEG C, wherein the adhesive is a polyvinyl alcohol solution having a mass concentration of 5 percent, and is 3 percent of total mass of the powder. The prepared ceramic has excellent sintering performance at 850 DEG C, has a dielectric constant of 22.1-22.9, a quality factor Qf of 75000-98000GHz and small resonant frequency temperature coefficient, and has a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

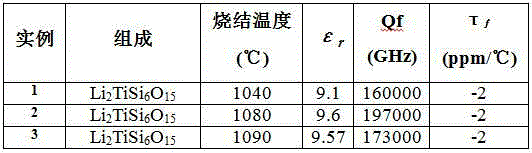

Ultra-low dielectric constant temperature-stable type microwave dielectric ceramic Li2TiSi6O15

The invention discloses an ultra-low dielectric constant temperature-stable type microwave dielectric ceramic Li2TiSi6O15 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and preparing Li2CO3, TiO2 and SiO2 raw powder with the purity of more than or equal to 99.9wt% according to the composition of the Li2TiSi6O15; (2) performing wet type ball milling and mixing on raw materials in the step (1) for 12 hours through a ball milling medium of distilled water, drying and preburning for 6 hours in the air atmosphere at a temperature of 990 DEG C; and (3) adding a binder into the powder obtained in the step (2), granulating, performing pressure forming, and finally sintering for 4 hours in the air atmosphere at a temperature of 1040-1090 DEG C, wherein a 5wt% polyvinyl alcohol solution is adopted as the binder, and the addition amount of the polyvinyl alcohol accounts for 3% of total mass of the powder. The prepared ceramic is well sintered at 1100 DEG C below, the dielectric constant is up to 9.1-9.6, the quality factor Qf value is up to 160000-197000 GHz, the resonance frequency temperature coefficient is small, and the ultra-low dielectric constant temperature-stable type microwave dielectric ceramic Li2TiSi6O15 has great application values industrially.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

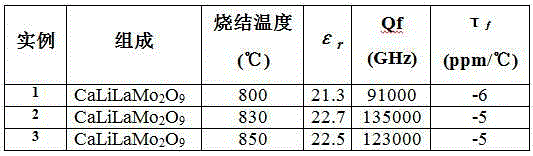

High-quality-factor low-dielectric-constant microwave dielectric ceramic CaLiLaMo2O9

The invention discloses a temperature-stable low-dielectric-constant microwave dielectric ceramic CaLiLaMo2O9 capable of being sintered at a low temperature and a preparation method of the dielectric ceramic. The preparation method comprises the following steps: (1) weighing powdery raw materials CaCO3, Li2CO3, La2o3 and MoO3 having the purity of 99.9wt% and blending together according to the constitution of CaLiLaMo2O9; (2) mixing the raw materials weighed in the step (1) for 12 hours by virtue of wet ball milling in the presence of distilled water serving as a ball milling medium, drying and then pre-burning in the air atmosphere at 750 DEG C for 6 hours; and (3) adding a binder to the powder obtained in the step (2) and pelletizing, and then pressing for forming, and finally, sintering in the air atmosphere at 800-850 DEG C for 4 hours, wherein the binder is a polyvinyl alcohol solution having the mass concentration of 5%, and the addition of the polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic can be well sintered at a temperature below 850 DEG C; the dielectric constant of the ceramic reaches 21.3-22.7, and the quality factor (Qf) value of the ceramic is high up to 91000-135000GHZ; besides, the ceramic is low in resonant frequency temperature coefficient and has an extremely high application value in the industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

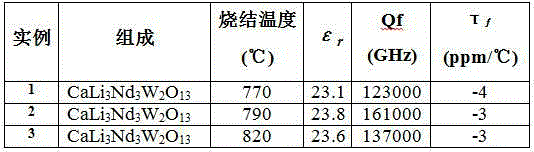

Temperature-stable low-dielectric-constant microwave dielectric ceramic CaLi3Nd3W2O13

The invention discloses a high-quality-factor temperature-stable low-dielectric-constant microwave dielectric ceramic CaLi3Nd3W2O13 and a preparation method thereof. The method comprises the following steps: (1) CaCO3, Li2CO3, Nd2O3 and WO3 original powders with purities higher than 99.9% (weight percentage) are weighed and blended according to the composition of CaLi3Nd3W2O13; (2) the raw material obtained in the step (1) is subjected to wet ball milling for 12h, wherein a ball milling medium is distilled water; after drying, the material is pre-sintered for 6h under a temperature of 720 DEG C in an air atmosphere; and (3) a binding agent is added to the powder obtained in the step (2), granulation and compression molding are carried out; and sintering is carried out for 4h under a temperature of 770-820 DEG C in an air atmosphere. The binding agent is a polyvinyl alcohol solution with a mass concentration of 5%, wherein the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic provided by the invention can be well sintered under a temperature below 820 DEG C. The dielectric constant of the ceramic reaches 23.1-23.8, and the quality factor Qf of the ceramic reaches 123000-161000GHz. The ceramic has a low resonance frequency temperature coefficient, and has high application value in industrial application.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

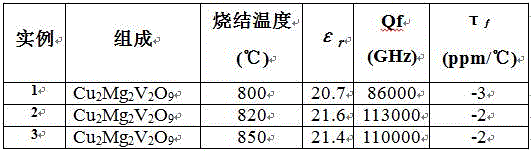

High-quality-factor temperature-stable type low-dielectric-constant microwave dielectric ceramic Cu2Mg2V2O9

The invention discloses high-quality-factor temperature-stable type low-dielectric-constant microwave dielectric ceramic Cu2Mg2V2O9 and a preparation method thereof. The method includes the steps of firstly, weighing and preparing original powder of CuO, MgO and V2O5 with purity of 99.9% or higher by weight percentage according to the composition of Cu2Mg2V2O9; secondly, conducting wet type ball mill mixing on the raw materials in the first step for 12 hours with distilled water as the ball mill medium, and presintering the material in the air atmosphere of 750 DEG C for 6 hours after drying; thirdly, adding an adhesive to the powder prepared in the second step to be granulated, conducting pressing forming, and sintering the product in the air atmosphere of 800-850 DEG C for 4 hours, wherein a polyvinyl alcohol solution with mass concentration of 5% is adopted as the adhesive, and the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at a temperature of 850 DEG C or lower, has the dielectric constant of 20.7-21.6, the quality factor Qf of 86000-113000 GHz and the small resonant frequency temperature coefficient and has extremely large industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

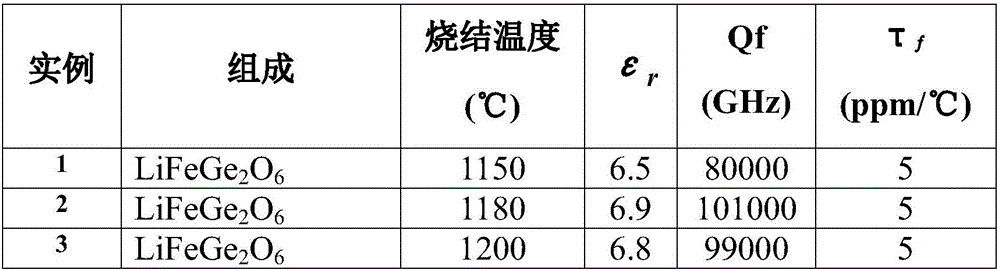

High-quality-factor stable-temperature microwave dielectric ceramic LiFeGe2O6

The invention discloses high-quality-factor stable-temperature ultralow dielectric constant microwave dielectric ceramic LiFeGe2O6 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and proportioning original powder (with the purity of 99.9% or above by weight) of Li2CO3, Fe2O3 and GeO2 according to composition of LiFeGe2O6; (2) performing wet-type ball-milling and mixing on the raw materials obtained in the step (1) for 12 h, drying and then pre-burning for 6 h in the atmosphere of 1100 DEG C, wherein the ball-milling medium is distilled water; (3) adding a binder into the powder prepared in the step (2), pelletizing, then pressing for shaping, and finally, sintering for 4 h in the atmosphere of 1,150-1,200 DEG C, wherein the binder is a polyvinyl alcohol solution with the mass concentration of 5%, and polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared high-quality-factor stable-temperature microwave dielectric ceramic LiFeGe2O6 has excellent sintering performance below 1,200 DEG C, has the dielectric constant of 6.5-6.9 and the quality factor Qf of 80,000-101,000 GHz, is small in temperature coefficient of resonance frequency and has an extremely high application value in the industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

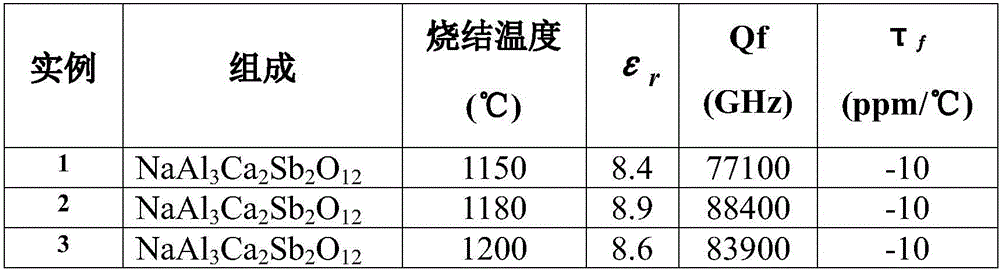

Application of compound oxide NaAl3Ca2Sb2O12 in serving as temperature-stable type microwave dielectric ceramic

The invention discloses application of compound oxide NaAl3Ca2Sb2O12 in serving as temperature-stable type microwave dielectric ceramic and a preparation method of the compound oxide. The preparation method comprises the following steps: (1) weighing and proportioning chemical raw materials, i.e. Na2CO3, Al2O3, CaCO3 and Sb2O5 powder, according to the chemical formula NaAl3Ca2Sb2O12; (2) performing wet type ball grinding on the raw materials in the step (1) for mixing for 12 hours through distilled water serving as a ball grinding medium, drying the materials, and pre-sintering in the air atmosphere at the temperature of 1,100 DEG C for 6 h; (3) adding an adhesive into the powder obtained in the step (2), performing granulation and pressing molding in sequence, and finally sintering in the air atmosphere at the temperature of 1,150 to 1,200 DEG C for 4 hours, wherein the adhesive is a polyvinyl alcohol solution with the mass concentration of 5 percent, and the adding amount of polyvinyl alcohol is 3 percent of the total mass of the powder. The ceramic prepared by the method disclosed by the invention can be well sintered at the temperature of 1,200 DEG C or below; the dielectric constant is 8.4 to 8.9, and the quality factor Qf is 77,100 to 88,400 GHz; the resonant frequency and the temperature coefficient are small; the compound oxide NaAl3Ca2Sb2O12 has extremely high application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

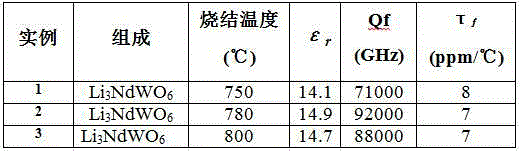

Microwave dielectric ceramic Li3NdWO6 with ultralow dielectric constant and preparation method thereof

The invention discloses a temperature stable ultralow dielectric constant microwave dielectric ceramic Li3NdWO6 capable of being sintered at a low temperature and a preparation method thereof. The preparation method comprises the steps of (1) weighing and proportioning original powder of Li2CO3, Nd2O3 and WO3 of which the purities are more than 99.9 weight percent according to the composition of Li3NdWO6; (2) performing wet ball milling and mixing on the raw materials of the step (1) for 12 hours by adopting a ball milling medium which is distilled water, drying, and then pre-sintering in atmosphere of 700 DEG C for 6 hours; and (3) adding an adhesive into the powder prepared in the step (2), granulating, pressing, molding, and finally, sintering in atmosphere of 750-800 DEG C for 4 hours, wherein the adhesive is a polyvinyl alcohol solution of which the mass concentration is 5%, and the adding quantity of the polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at 750-800 DEG C, the dielectric constant reaches 14.1-14.9, the quality factor (Qf) value is up to 71,000-92,000GHz, and the temperature coefficient of resonance frequency of the ceramic is small, so the ceramic has great application value in industry.

Owner:临泉县非凡装饰工程有限公司

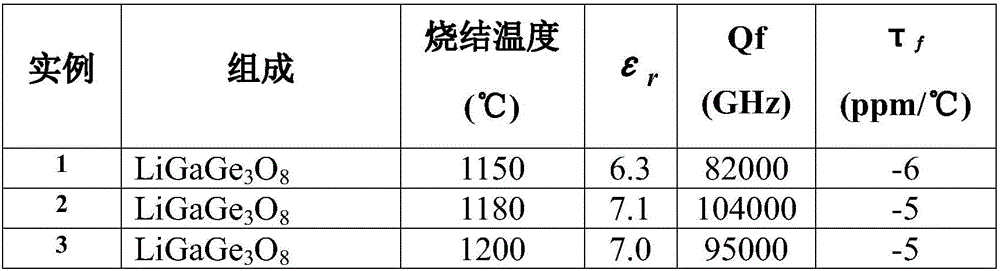

Temperature-stable type microwave dielectric ceramic LiGaGe3O8 with high Qf(quality factor)

The invention discloses a low-loss and temperature-stable type microwave dielectric ceramic LiGaGe3O8 with an ultralow dielectric constant and a preparation method of the microwave dielectric ceramic. The preparation method comprises steps as follows: (1), original powder of Li2CO3, Ga2O3 and GeO2 with the purity of 99.9% or higher (in percentage by weight) is weighed and blended according to composition of LiGaGe3O8; (2), the raw materials in the step (1) are subjected to wet ball-milling and mixing for 12 h, the ball-milling medium is distilled water, and a mixture is dried and then is pre-sintered for 6 h in air atmosphere at the temperature of 1,100 DEG C; (3), a binding agent is added to the powder prepared in the step (2), and a mixture is subjected to pelleting and compression molding and is sintered for 4 h in air atmosphere at the temperature of 1,150-1,200 DEG C, wherein the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the adding amount of polyvinyl alcohol is 3% of total mass of the powder. The ceramic prepared with the method is sintered well at the temperature of 1,200 DEG C or lower, the dielectric constant reaches 6.3-7.1, the Qf(quality factor) value of the ceramic reaches 82,000-104,000 GHz, the temperature coefficient of resonance frequency is small, and the microwave dielectric ceramic has great industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

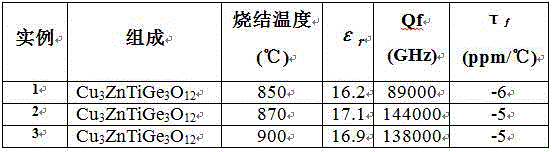

Microwave dielectric ceramic Cu3ZnTiGe3O12 with high quality factor and ultralow dielectric constant and preparation method of microwave dielectric ceramic Cu3ZnTiGe3O12

The invention discloses temperature-stable microwave dielectric ceramic Cu3ZnTiGe3O12 with high quality factor and ultralow dielectric constant and a preparation method of the microwave dielectric ceramic Cu3ZnTiGe3O12. The preparation method comprises steps as follows: (1), original powder of CuO, ZnO, TiO2 and GeO2 with the purity higher than 99.9% in percentage by weight is weighed and blended according to composition of Cu3ZnTiGe3O12; (2), raw materials in the step (1) are subjected to wet ball milling and mixing for 12 h, a ball milling medium adopts distilled water, and the raw materials are dried and then pre-sintered in the atmosphere at the temperature of 800 DEG C for 6 h; (3), a binder is added to powder prepared in the step (2), the mixture is subjected to granulation and compression molding and is sintered in the atmosphere at the temperature of 850-900 DEG C for 4 h finally; the binder adopts a polyvinyl alcohol solution with the mass concentration of 5%, and polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at the temperature lower than 900 DEG C, the dielectric constant reaches 16.2-17.1, the quality factor Qf of the ceramic is up to 89,000-144,000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

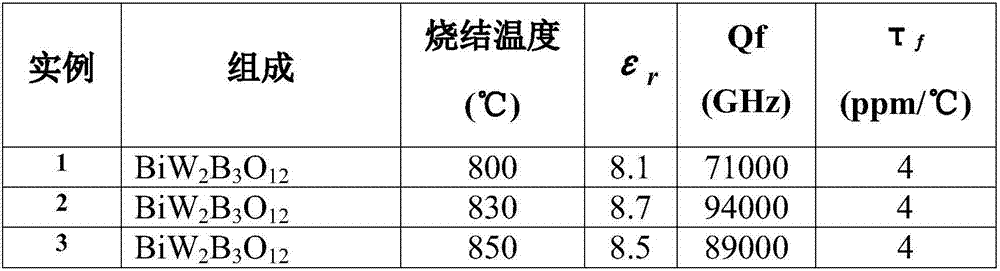

Bismuth-containing borate microwave dielectric ceramic with ultra-low dielectric constant

The invention discloses bismuth-containing borate microwave dielectric ceramic BiW2B3O12 with an ultra-low dielectric constant and a preparation method thereof. The method comprises the following steps: (1) weighing initial powder of Bi2O3, WO3 and B2O3 having the purity of over 99.9 percent by weight according to the composition of BiW2B3O12; (2) mixing the raw materials in the step (1) by a wet ball mill for 12 hours by taking distilled water as a ball mill medium, drying, and preburning for 6 hours at an atmosphere of 750 DEG C; (3) adding an adhesive into the powder prepared in the step (2), granulating, pressing and molding, and sintering for 4 hours at atmosphere of 800-850 DEG C, wherein the adhesive is a polyvinyl alcohol solution having a mass concentration of 5 percent, and is 3 percent of total mass of the powder. The prepared ceramic has excellent sintering performance at 850 DEG C, has a dielectric constant of 8.1-8.7, a quality factor Qf of 71000-94000GHz and small resonant frequency temperature coefficient, and has a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

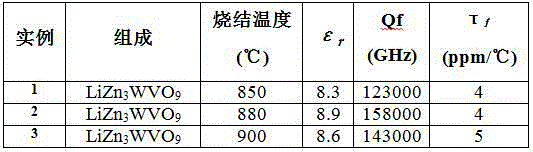

Temperature-stable ultralow-dielectric-constant microwave dielectric ceramic LiZn3WVO9

The invention discloses a low-temperature-sintering temperature-stable ultralow-dielectric-constant microwave dielectric ceramic LiZn3WVO9 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and proportioning Li2CO3, ZnO, WO3 and V2O5 original powders with the purity of higher than 99.9 wt% according to the composition of the LiZn3WVO9; (2) carrying out wet ball milling mixing on the raw materials in the step (1) for 12 hours by using distilled water as a ball milling medium, drying, and presintering in an 800-DEG C atmospheric atmosphere for 6 hours; and (3) adding an adhesive into the powder prepared in the step (2), granulating, compacting, and finally, sintering in an 850-900-DEG C atmospheric atmosphere for 4 hours, wherein the adhesive adopts a 5 wt% polyvinyl alcohol solution, and the addition amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic has favorable sintering property at 950 DEG C, the dielectric constant reaches 8.3-8.9, the quality factor Qf value is up to 123000-158000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

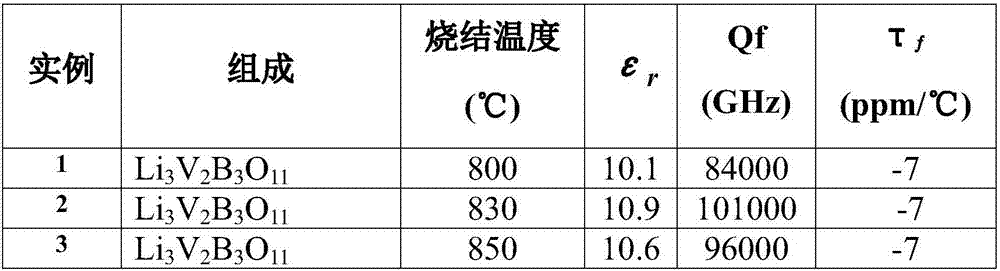

Vanadium-containing borate microwave dielectric ceramic with ultra-low dielectric constant

The invention discloses vanadium-containing borate temperature stabilized microwave dielectric ceramic Li3V2B3O11 with an ultra-low dielectric constant and a preparation method thereof. The method for preparing the microwave dielectric ceramic comprises the following steps: (1) weighing initial powder of Li2CO3, V2O5 and B2O3 having the purity of over 99.9 percent by weight according to the composition of Li3V2B3O11; (2) mixing the raw materials in the step (1) by a wet ball mill for 12 hours by taking distilled water as a ball mill medium, drying, and preburning for 6 hours at an atmosphere of 750 DEG C; (3) adding an adhesive into the powder prepared in the step (2), granulating, pressing and molding, and sintering for 4 hours at atmosphere of 800-850 DEG C, wherein the adhesive is a polyvinyl alcohol solution having a mass concentration of 5 percent, and is 3 percent of total mass of the powder. The prepared ceramic has excellent sintering performance at 850 DEG C, has a dielectric constant of 10.1-10.9, a quality factor Qf of 84000-101000GHz and small resonant frequency temperature coefficient, and has a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

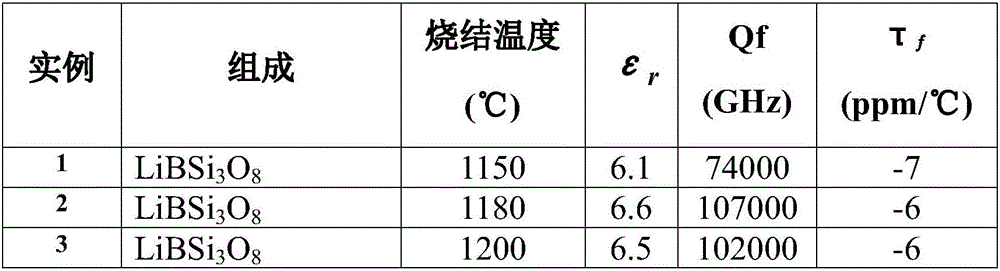

Low-loss temperature-stable microwave dielectric ceramic LiBSi3O8

The invention discloses low-loss temperature-stable ultralow-dielectric-constant microwave dielectric ceramic LiBSi3O8 and a preparation method thereof. The preparation method includes: (1), weighing and blending original powder of Li2CO3, B2O3 and SiO2 higher than 99.9% (weight percent) in purity according to composition of LiBSi3O8; (2), subjecting raw materials of the step (1) to wet ball-milling and mixing for 12h, drying, and pre-sintering in an atmosphere of 1100 DEG C for 6h, wherein a ball-milling medium is distilled water; (3), adding a binder into powder obtained in the step (2), granulating, pressing for forming, and sintering in an atmosphere of 1150-1200 DEG C for 4h, wherein polyvinyl alcohol solution of 5% in mass concentration is adopted as the binder, and adding amount of polyvinyl alcohol accounts for 3% of total weight of the powder. The ceramic prepared by the method is good in sintering performance at temperature below 1200 DEG C, dielectric constant reaches 6.1-6.6, quality factor Qf of the ceramic is up to 74000-107000GHz, resonant frequency temperature coefficient is low, and the ceramic has huge application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

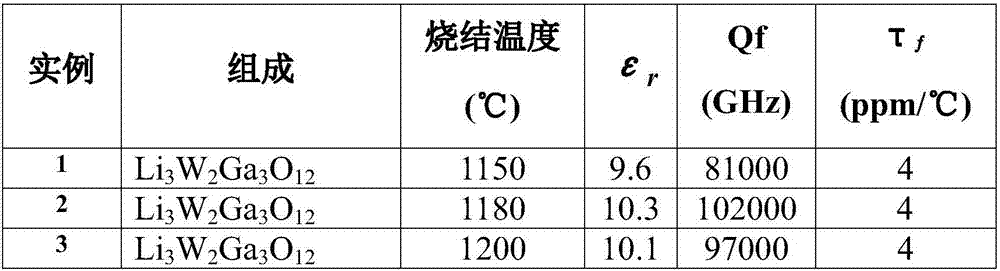

Gallate ultra-low dielectric constant microwave dielectric ceramic

The invention discloses a gallate temperature-stable ultra-low dielectric constant microwave dielectric ceramic Li3W2Ga3O12 and a preparation method thereof. The method comprises the steps of (1) weighing and burdening original powder of Li2CO3, WO3 and Ga2O3, of which the purity is greater than 99.9% (percentage by weight) according to composition of the Li3W2Ga3O12; (2) carrying out wet ball-mill mixing on the raw materials in the step (1) for 12h, wherein the ball-milling medium is distilled water, drying and then pre-sintering in an air atmosphere of 1100 DEG C for 6h; and (3) adding a binder to the powder prepared in the step (2), granulating, carrying out compression moulding and finally sintering in the air atmosphere of 1150-1200 DEG C for 4h, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted by the binder and the additive amount of polyvinyl alcohol accounts for 3% of total mass of the powder. The prepared ceramic has good sintering property below 1200 DEG C, the dielectric constant reaches 9.6-10.3, the quality factor Qf value reaches 81,000-102,000GHz, the temperature coefficient of the resonance frequency is small and the prepared ceramic has great industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

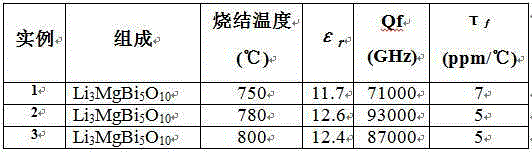

Microwave dielectric ceramic Li3MgBi5O10 with ultralow dielectric constant and preparation method thereof

The invention discloses a high-quality and stable microwave dielectric ceramic Li3MgBi5O10 with an ultralow dielectric constant and a preparation method thereof, wherein the dielectric ceramic can be sintered at a low temperature. The preparation method comprises the following steps: (1) weighing the following powder with purity (weight percentage) of 99.9% or more: Li2O3, MgO, and Bi2O3 according to the composition of Li3MgBi5O10; (2) subjecting the raw materials prepared in the step (1) to 12 hours of wet ball milling to mix the powder, wherein distilled water is taken as the medium of ball milling, drying the mixture, and then pre-burning the mixture at a temperature of 700 DEG C in atmosphere for 6 hours; (3) adding an adhesive into the powder obtained in the step (2), carrying out granulation, pressing, moulding, and finally sintering the granules at a temperature of 750 to 800 DEG C in atmosphere for 4 hours; wherein the adhesive is a polyvinyl alcohol solution with a mass concentration of 5%, and the added polyvinyl alcohol accounts for 3% of the total weight of the powder. The prepared ceramic can be well sintered at a temperature of 800 DEG C, the dielectric constant can reach 11.7 to 12.6, the quality factor (Qf) value can reach 71000 to 93000 GHz, the temperature coefficient of resonance frequency is small, and thus the provided microwave dielectric ceramic has a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

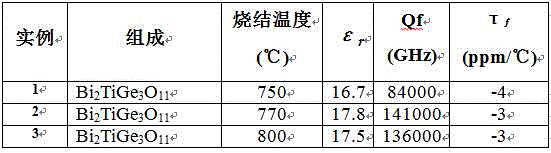

Temperature-stable microwave dielectric ceramic Bi2TiGe3O11 allowing low temperature sintering and preparation method thereof

The invention discloses a temperature-stable microwave dielectric ceramic Bi2TiGe3O11 allowing low temperature sintering and a preparation method thereof. The method is as below: (1) weighing analytically pure raw materials of Bi2O3, TiO and GeO2 powders according to a stoichiometric formula Bi2TiGe3O11; (2) mixing the raw materials in the step (1) by wet ball milling for 12 h by using a milling medium of distilled water, drying and pre-sintering in the atmosphere at 700 DEG C for 6 h; and (3) adding a binder into the powder obtained in the step (2) and pelletizing, then pressing for forming, and finally sintering in the atmosphere at 750-800 DEG C for 4 h, wherein the binder is a polyvinyl alcohol solution with mass concentration of 5%, and the addition of the polyvinyl alcohol accounts for 3 wt.% of the total amount of the powder. The ceramic prepared by the invention has the advantages of good sintering property at the temperature below 800 DEG C, dielectric constant of 16.7-17.8, quality factor Qf of up to 84000-141000 GHz, small resonance frequency temperature coefficient, and a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

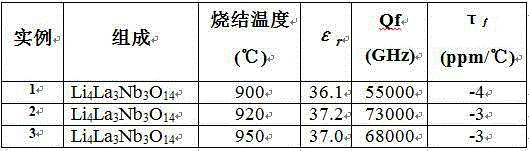

Microwave dielectric ceramic Li4La3Nb3O14 with medium dielectric coefficient and preparation method of microwave dielectric ceramic Li4La3Nb3O14

The invention discloses low-temperature sintered temperature-stable type microwave dielectric ceramic Li4La3Nb3O14 with a medium dielectric coefficient and a preparation method of the microwave dielectric ceramic Li4La3Nb3O14. The preparation method comprises steps as follows: (1), original powder of Li2CO3, La2O3 and Nb2O5 with the purity higher than 99.9% in percentage by weight is weighed in the composition proportion of Li4La3Nb3O14 and mixed; (2), the raw material in the step (1) is subjected to wet type ball milling and mixing in distilled water serving as a ball milling medium for 12 hours and pre-sintered for 6 hours in an air atmosphere with the temperature of 850 DEG C after being dried; (3), a binder is added to powder prepared in the step (2), the mixture is granulated, pressed to be shaped and sintered for 4 hours in the air atmosphere with the temperature ranging from 900 DEG C to 950 DEG C, the binder adopts a polyvinyl alcohol solution with the mass concentration being 5%, and the adding quantity of the polyvinyl alcohol solution accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered under 960 DEG C, the dielectric coefficient reaches 36.1-37.2, the Qf (quality factor) of the ceramic is as high as 55,000-73,000 GHz, the temperature coefficient of resonance frequency is low, and the ceramic has great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

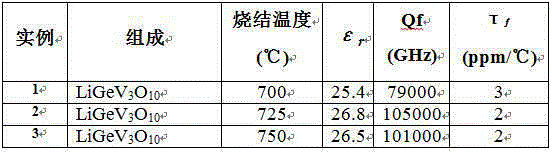

Temperature-stable microwave dielectric ceramic LiGeV3O10 and preparation method therefor

The invention discloses a high-quality-factor temperature-stable low-dielectric-constant microwave dielectric ceramic LiGeV3O10 and a preparation method therefor. The preparation method comprises the following steps: (1) weighing and batching raw powder of Li2CO3, V2O5 and GeO2, the purity of which is 99.9% (percentage by weight) according to constitution of the LiGeV3O10; (2) performing wet-type ball-milling mixing on the raw materials obtained in the step (1) for 12 hours by using a ball-milling medium of distilled water, drying and pre-baking the powderfor 6 hours in an air atmosphere at the temperature of 650 DEG C; and (3) adding an adhesive into the powder prepared in the step (2), granulating the powder, performing compression molding and finally sintering on the powder for 4 hours in the air atmosphere at the temperature of 700 to 750 DEG C, wherein the adhesive is a polyvinyl alcohol solution, the concentration by mass of which is 5%, and the amount of added polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the method disclosed by the invention is well sintered at 750 DEG C, is as high as 25.4 to 26.8 in dielectric constant, is as high as 79000GHz to 105000GHz in quality factor Qf value, small in temperature coefficient of resonance frequency and extremely large in industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

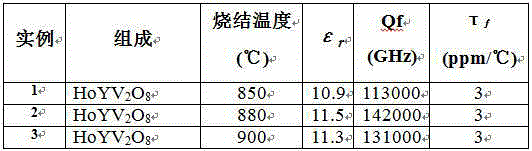

Ultra-low dielectric constant microwave dielectric ceramic HoYV2O8 with high thermal stability and low loss

The invention discloses temperature-stable ultra-low dielectric constant microwave dielectric ceramic HoYV2O8 which is of a tetragonalzirconia structure and can be sintered at low temperature and a preparation method thereof. The preparation method comprises the steps that 1, Ho2O3, Y2O3 and V2O5 original powder with the purity above 99.9 percent by weight is weighed and batched according to the composition of the HoYV2O8; 2, wetted ball grinding and mixing are performed on the raw materials in the step 1 for 12 hours, a ball milling medium adopts distilled water, and presintering is performed on the mixture in the air atmosphere at 800 DEG C for six hours after the mixture is dried; 3, a binding agent is added in powder prepared in the step 2, pelleting is performed, then compression moulding is performed, and lastly sintering is performed in the air atmosphere at 850-900 DEG C for four hours, wherein the binding agent adopts a polyving akohol solution with the mass concentration of 5 percent, and the additive amount of polyving akohol accounts for 3 percent of the total mass of the powder. The prepared ceramic can be well sintered below 900 DEG C, the dielectric constant reaches 10.9 to 11.5, the quality factor Qf value reaches up to 113000-142000 GHz, the temperature coefficient of resonance frequency is small, and the great application value is achieved in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

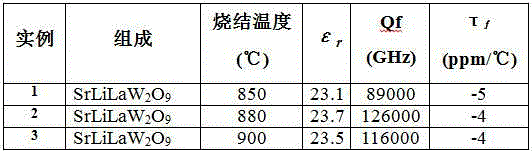

High-quality factor low-dielectric constant microwave dielectric ceramic SrLiLaW2O9

The invention discloses temperature-stable low-dielectric constant microwave dielectric ceramic SrLiLaW2O9 and a preparation method thereof, wherein the microwave dielectric ceramic can be sintered at a low temperature. The preparation method comprises the following steps: (1) weighing original powder of SrCO3, Li2CO3, La2O3 and WO3 according to the composition of SrLiLaW2O9 for compounding, wherein the purities are 99.9 percent or higher by weight percent; (2) conducting wet ball mill mixing on the raw materials obtained in the step (1) for 12 hours, carrying out drying, and pre-burning the dried mixture in a 800 DEG C air atmosphere for 6 hours, wherein distilled water is taken as a ball mill medium; (3) adding a binder into the powder obtained in the step (2), carrying out pelleting and pressure molding, and sintering in a 850 to 900 DEG C air atmosphere for 4 hours, wherein the binder adopts a polyvinyl alcohol solution of which the mass concentration is 5 percent, and the add amount of the polyvinyl alcohol solution is 3 percent of the total weight of the powder. The microwave dielectric ceramic prepared according to the preparation method can be well sintered at 900 DEG C or a lower temperature, reaches 23.1 to 23.7 in dielectric constant and 89000 to 126000 GHz in quality factor Qf, is low in temperature coefficient of resonance frequency, and has a very high application value in the industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

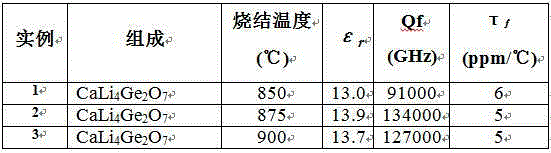

High-quality-factor temperature-stable type microwave dielectric ceramic CaLi4Ge2O7 and preparation method thereof

The invention discloses a high-quality-factor temperature-stable type ultralow-dielectric-constant microwave dielectric ceramic CaLi4Ge2O7 and a preparation method thereof. The preparation method comprises the steps: (1) weighing and burdening CaCO3, Li2CO3 and GeO2 original powders with the purity of more than or equal to 99.9 wt% according to the composition of CaLi4Ge2O7; (2) carrying out wet ball-milling mixing of the raw materials of the step (1) for 12 h with a ball-milling medium of distilled water, drying, and then pre-sintering for 6 h in an 800 DEG C air atmosphere; and (3) adding a binder to the powder obtained in the step (2), granulating, then pressing and molding, and finally sintering for 4 h in an 850-900 DEG C air atmosphere, wherein the binder adopts a polyvinyl alcohol solution with the mass concentration of 5% and the adding amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at the temperature of 900 DEG C or less, has the dielectric constant reaching 13.0-13.9, has the quality factor Qf value as high as 91000-134000 GHz, has small resonant frequency temperature coefficient, and has great application value in industries.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

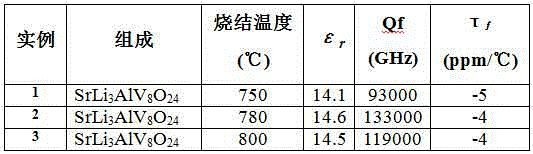

Microwave dielectric ceramic SrLi3AlV8O24 with ultralow dielectric constant and preparation method thereof

The invention discloses a high-quality-factor temperature-stable ultra-low dielectric constant microwave dielectric ceramic SrLi3AlV8O24 capable of being sintered at low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) weighing initial powder of SrCO3, Li2CO3, A12O3 and V2O5 with the purity over 99.9 % (weight percent) according to the composition of SrLi3AlV8O24 and carrying out batching; (2) carrying out wet-type ball-milling on the raw materials in step (1) for 12 hours, wherein the ball-milling medium is distilled water, and performing pre-sintering for 6 hours in the air atmosphere of 700 DEG C after drying; (3) adding a binder into the powder prepared in step (2) to pelletize the powder, carrying out compression moulding, and finally sintering the formed ceramic in the air atmosphere of 750-800 DEG C for 4 hours, wherein the binder adopts a polyvinyl alcohol solution with the mass concentration of 5 %, and the additive amount of polyvinyl alcohol takes up 3 % of total powder mass. The ceramic prepared from the invention is good in sintering under the temperature of 800 DEG C; the dielectric constant reaches 14.1-14.6; the quality factor Qf value of the ceramic reaches up to 93000-133000 GHz; the resonant frequency temperature coefficient is small; the ceramic has huge application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

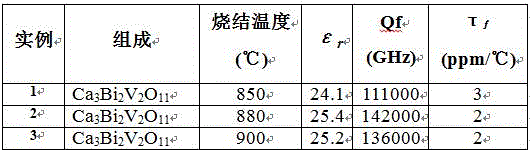

High-quality-factor low-dielectric-constant microwave dielectric ceramic Ca3Bi2V2O11

The invention discloses a high-quality-factor low-dielectric-constant microwave dielectric ceramic Ca3Bi2V2O11 and a preparation method thereof. The method includes: (1) weighing and mixing original powder of V2O5, Bi2O3 and CaO with the purity higher than 99.9% (weight percentage) according to composition of Ca3Bi2V2O11; (2) subjecting the materials at the step (1) to wet ball-mill mixing for 12h with distilled water serving as a ball milling medium, drying, and pre-sintering for 6h in the air atmosphere of 800 DEG C; (3) adding a binding agent into powder obtained at the step (2), performing pelletizing and compression molding, and finally sintering for 4h in the air atmosphere of 850-900 DEG C, wherein a polyvinyl alcohol solution with the mass concentration being 5% serves as the binding agent, and addition amount of the polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared microwave dielectric ceramic Ca3Bi2V2O11 is excellent in sintering below 900 DEG C, is 24.1-25.4 in dielectric constant and up to 111000-142000GHz in quality factor Qf value and is low in temperature coefficient of resonance frequency, thereby being extremely high in industrial application value.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

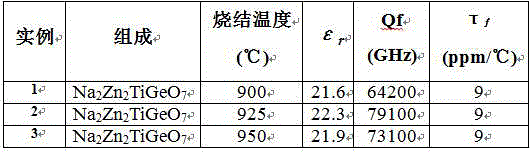

Low-dielectric-constant microwave dielectric ceramic Na2Zn2TiGeO7 and preparation method thereof

The invention discloses low-dielectric-constant microwave dielectric ceramic Na2Zn2TiGeO7 and a preparation method thereof. The preparation method comprises the steps that 1, chemical raw materials including Na2CO3, ZnO, TiO2 and GeO2 powder are weighed and blended according to the chemical stoichiometric equation Na2Zn2TiGeO7; 2, the raw materials in the step 1 are subjected to wet ball milling and mixing for 12 hours, distilled water serves as a ball milling medium, and the powder is pre-sintered for 6 hours in an air atmosphere at the temperature of 850 DEG C; 3, a binding agent is added to the powder obtained in the step 2, pelleting is carried out, then compression moulding is carried out, finally sintering is carried out for 4 hours in an air atmosphere at the temperature of 900 DEG C to 950 DEG C, a polyvinyl alcohol solution with the mass concentration of 5% serves as the binding agent, and the adding amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic is sintered well at the temperature of 1,000 DEG C or below, the dielectric constant ranges from 21.6 to 22.3, the quality factor Qf value of the ceramic reaches 64,200 GHz to 79,100 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has high application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

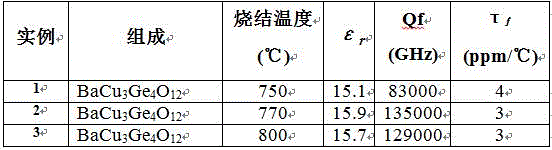

Low temperature sinterable temperature-stable microwave dielectric ceramic BaCu3Ge4O12 and preparation method thereof

The invention discloses low temperature sinterable temperature-stable microwave dielectric ceramic BaCu3Ge4O12 and a preparation method thereof. The preparation method comprises the steps of (1) weighing and blending powder of analytically pure chemical raw materials of BaCO3, CuO and GeO2 according to the composition of BaCu3Ge4O12; (2) performing wetted ball grinding and mixing on the raw materials of step (1) for 12h, wherein the milling medium is distilled water, and after drying, presintering in 700 DEG C atmosphere for 6h; (3) adding a binding agent in the powder prepared in the step (2) and pelleting, then performing compression moulding, and finally sintering in 750 to 800 DEG C atmosphere for 4h; the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5 percent, and the additive amount of polyvinyl alcohol accounts for 3 percent of the total mass of the powder. The ceramic prepared by the invention is good in sintering at the temperature below 800 DEG C, the dielectric constant reaches 15.1 to 15.9, the quality factor Qf value reaches up to 83000 to 135000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

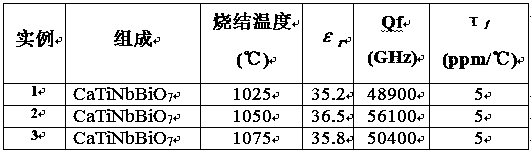

Temperature-stable middle-dielectric-constant microwave dielectric ceramic CaTiNbBiO7 and preparation method thereof

The invention discloses low-loss temperature-stable middle-dielectric-constant microwave dielectric ceramic CaTiNbBiO7 and a preparation method thereof. The method comprises the steps that 1, the chemical raw materials of CaCO3, TiO2, Nb2O5 and Bi2O3 powder are weighed and matched according to a stoichiometric formula CaTiNbBiO7; 2, wet ball milling and mixing are conducted on the raw materials obtained in the first step for 12 h, a ball milling medium adopts distilled water, and after drying is conducted, presintering is conducted for 6 h in the air atmosphere of 950 DEG C; 3, a binding agent is added to powder obtained in the second step, granulation is conducted, pressing forming is conducted, and sintering is conducted for 4 h in the air atmosphere of 1,025-1,075 DEG C. The binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. According to the low-loss temperature-stable middle-dielectric-constant microwave dielectric ceramic CaTiVBiO7 and the preparation method thereof, the prepared ceramic is sintered well at 1,100 DEG C or below, the dielectric constant reaches 35.2-36.5, the value of the quality factor Qf reaches up to 48,900-56,100 GHz, the temperature coefficient of the resonant frequency is small, and the microwave dielectric ceramic has great application value in the industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com