High-quality-factor stable-temperature microwave dielectric ceramic LiFeGe2O6

A microwave dielectric ceramic and temperature-stable technology, applied in the field of dielectric ceramic materials, can solve the problems of few single-phase microwave dielectric ceramics, low quality factor, and excessive temperature coefficient of resonant frequency, so as to meet the requirements of low-temperature co-firing technology and , good temperature stability, low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

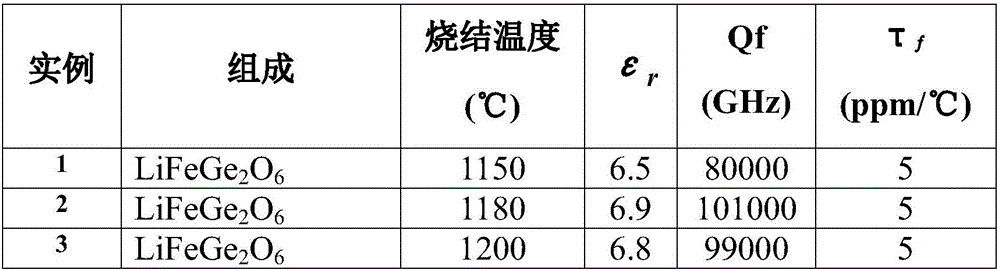

[0018] Table 1 shows three specific examples of different sintering temperatures constituting the present invention and their microwave dielectric properties. The preparation method is as above, and the microwave dielectric performance is evaluated by the cylindrical dielectric resonator method.

[0019] The ceramics can be widely used in the manufacture of microwave devices such as various dielectric substrates, resonators and filters, and can meet the technical needs of mobile communication and satellite communication systems.

[0020] Table 1:

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com