Bionic spade handle for reducing resistance and loosing deeply

A subsoiling shovel and shovel handle technology, applied in the field of deep loosening shovel handles, can solve the problem of high soil tillage resistance of machines and tools, and achieve the effects of reducing soil tillage resistance, stabilizing tillage quality, and expanding promotion and popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

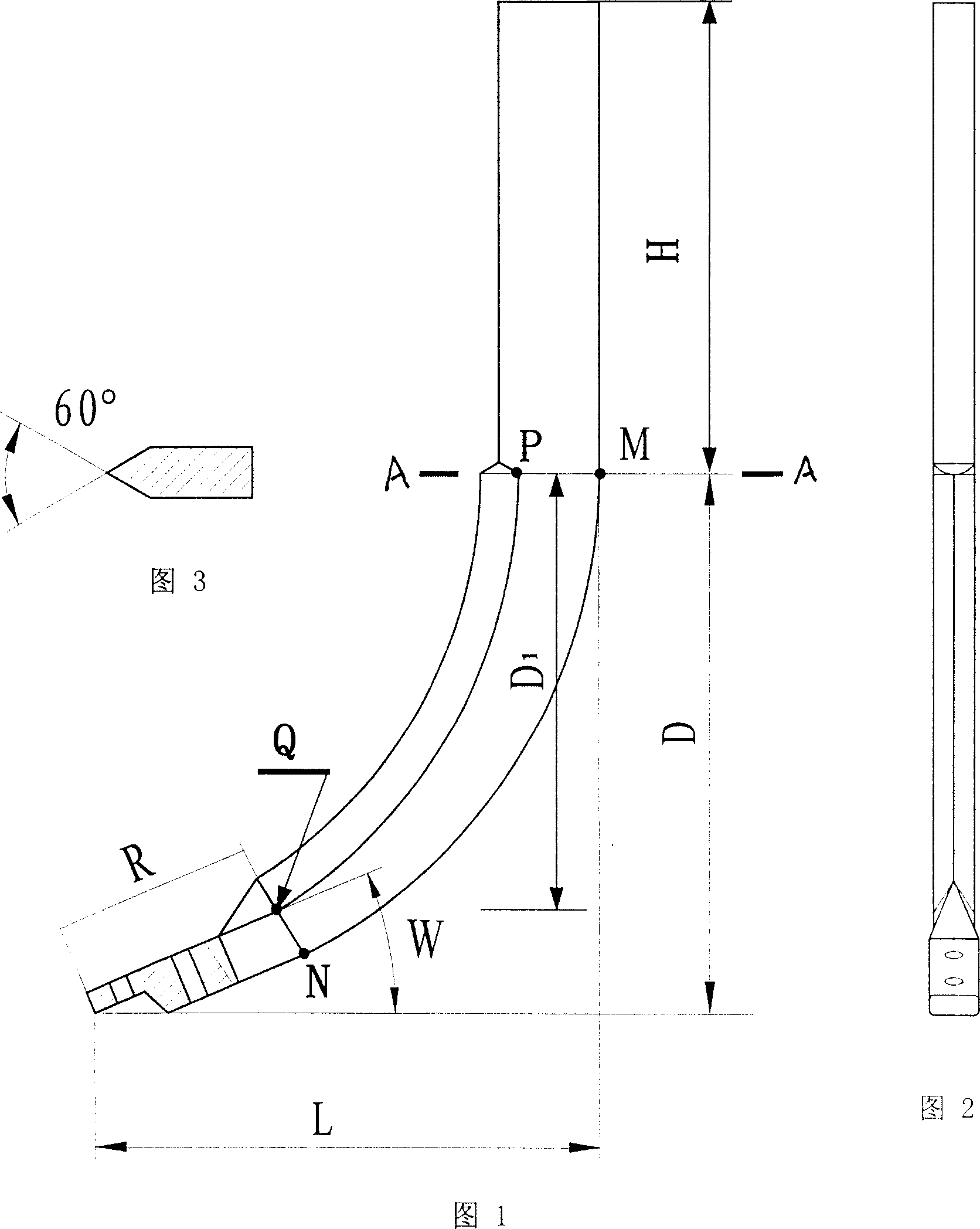

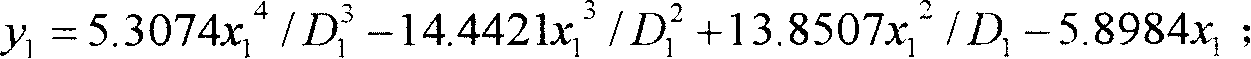

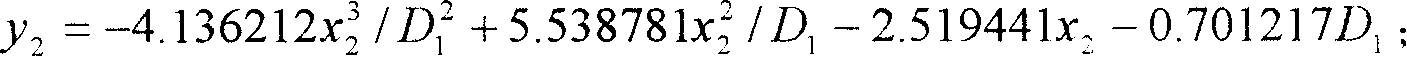

[0021] Two kinds of subsoiling shovel handles are designed and manufactured based on the two types of shovel tip structure dimensions and frame connection section dimensions stipulated in the Machinery Industry Standard of the People's Republic of China JB / T9788-1999 "Shovel Shovel and Shovel Handle".

[0022] 1. Light deep loose shovel handle

[0023] The known quantity is the design plowing depth D = 290mm. Deduct the working height of the subsoiling shovel tip according to the designed plowing depth D, and obtain the height D1 of the inner alignment PQ = 231.168mm.

[0024] ① by the equation y 1 = 5.3074 x 1 4 / D 1 3 - 14.4421 x 1 3 / D 1 2 + 13.8507 x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com