A vibrating subsoiling mechanism

A technology of deep loosening and cam mechanism, which is used in soil preparation machinery, mechanical equipment, transmission elements, etc., can solve the problems of severe vibration, high energy consumption, and uncompact structure of the vibration mechanism of the tractor, and achieve the effect of uniform and deep soil loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

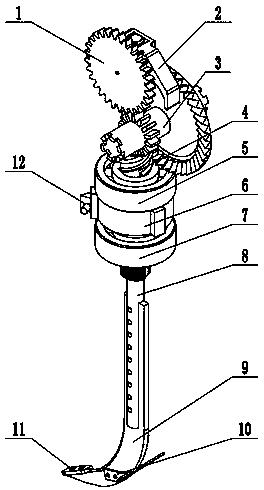

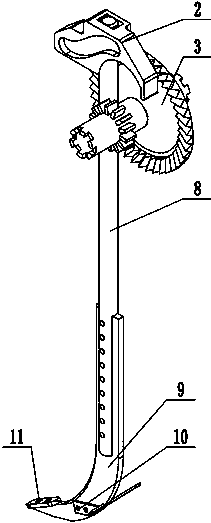

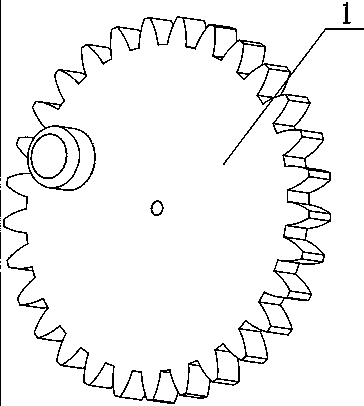

[0020] Embodiment: refer to attached Figure 1~6 , the present invention is a vibrating subsoiling mechanism, including a cam mechanism, a locking mechanism and a subsoiling device; the cam mechanism is composed of a protruding spur gear 1, a conversion cam 2, a gear shaft 3 and a guide rod 8, The spur gear part of the gear shaft 3 meshes with the protruding spur gear 1, the protruding part of the protruding spur gear 1 is connected with the S-shaped groove of the conversion cam 2, and the conversion cam 2 is threaded with the guide rod 8, Set a certain transmission ratio, the rotation of the gear shaft 3 drives the movement of the spur gear 1 with protrusions, and then through the conversion cam 2 in the cam mechanism, the rotation of the spur gear 2 with protrusions is converted into a motion connected with the conversion cam 2 The up and down linear motion of the guide rod 8, the guide rod 8 and the shovel handle of the subsoiling device drive the up and down linear motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com