Sliding-cutting type resistance-reducing deep loosening shovel

A deep loosening shovel and sliding cutting technology, applied in the field of deep loosening shovel, can solve problems such as large clods and large gaps, and achieve the effects of preventing soil erosion, reducing working resistance, and reducing tillage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

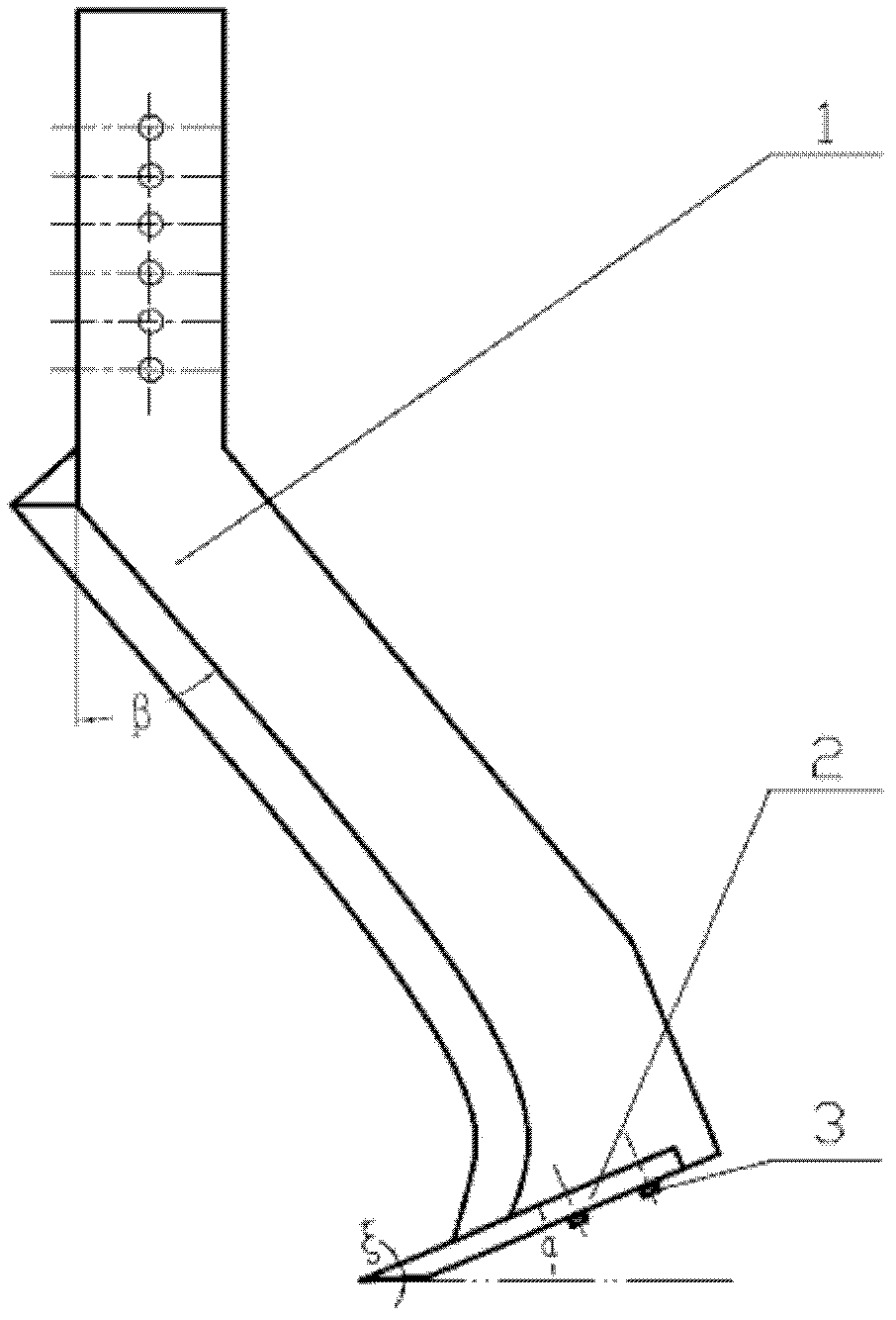

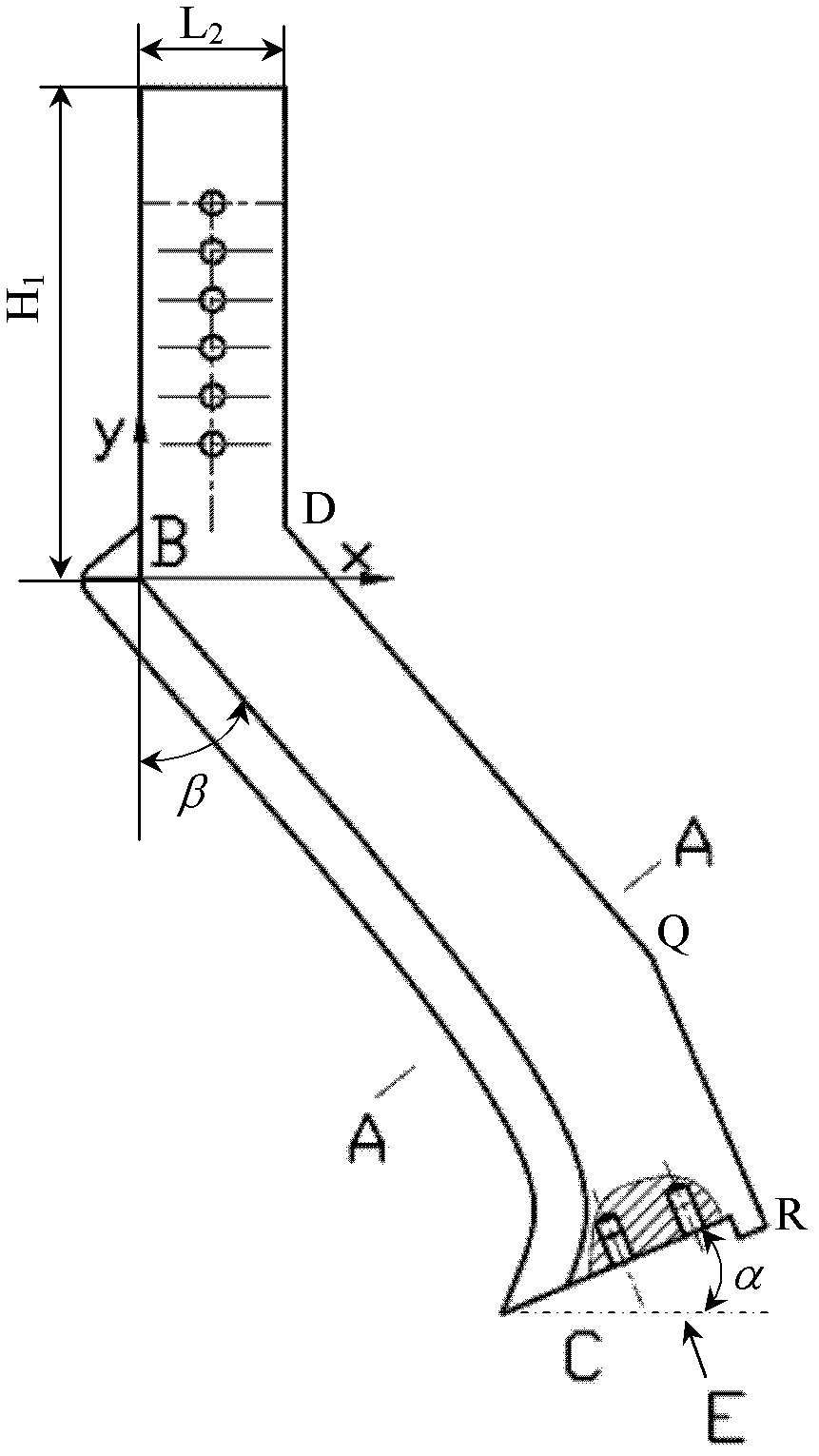

[0024] Taking the realization of the maximum tillage depth of 400mm as an example, the subsoiling shovel handle is made of Q275 steel not less than GB / T 700, and the width of the shovel handle is L. 2 The values of σ and thickness σ are 75mm and 30mm respectively, and the connection holes or fixtures are designed according to the installation requirements of the rack structure. Rack Connection Section H 1 The structural size range is 255mm. Shovel tip connecting section L, L 4 and bolt hole L 1 The values are 130mm, 145mm and 40mm respectively.

[0025] The inner directrix BC is determined by the polynomial equation The formed curve is obtained by taking the end point B on the inner directrix as the center of rotation and rotating ε in the counterclockwise direction at an angle of 40°. The calculation table of the x and y coordinates (unit: mm) of the BC segment is as follows:

[0026] x

0

85.42017

126.3856

156.3209

176.73

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com