Mini jockey pump

A thin-film pump and miniature technology, applied in the direction of pumps, pump control, pumps with flexible working elements, etc., can solve the problems of self-starting, complex structure, high production cost, etc., achieve reduced volume, reliable operation, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

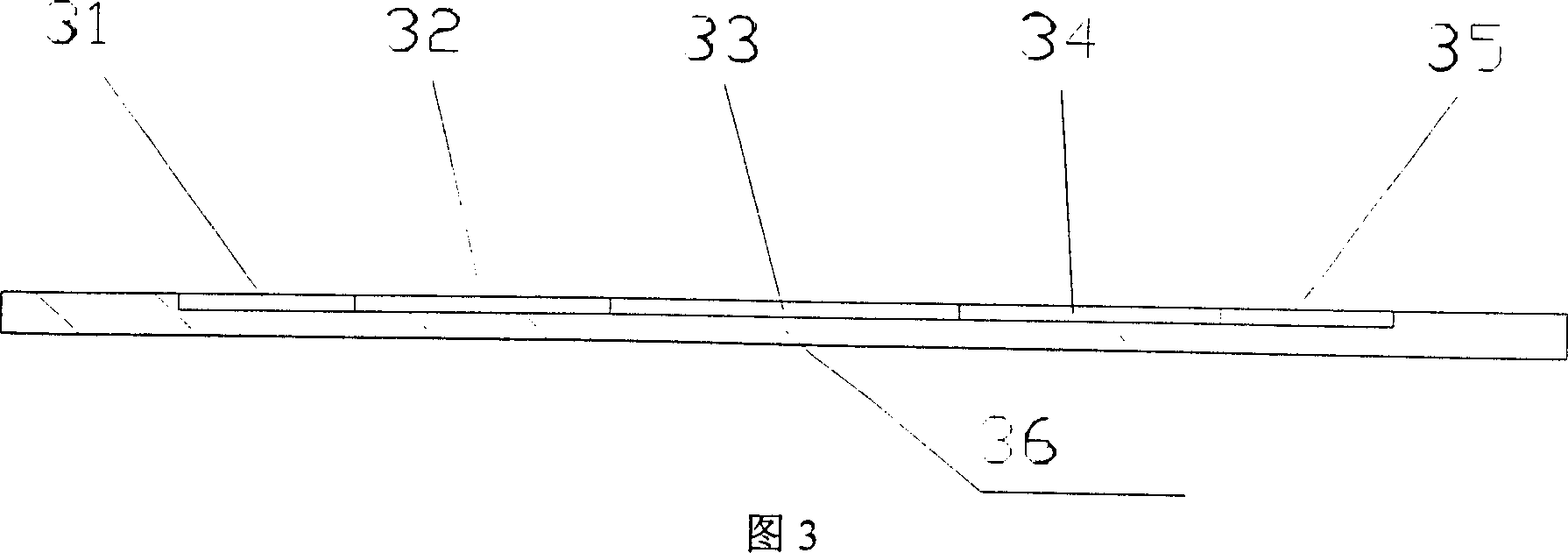

[0019] The structure of the pump body of Embodiment 1 is shown in Figure 4, wherein, the middle of the pump body is a circular pump cavity with a diameter of 4-8 mm, and both sides are circular liquid inlets 31 and liquid outlets 35, both of which have a diameter of 1 -3 mm, between the pump cavity and the liquid inlet and outlet, there are miniature cone valves 32 and microvalve 34 with the same direction, the small ports are 0.05-0.2 mm, the taper is 3-10 degrees, and the length is 2-4 mm.

[0020] The film material is polydimethylsiloxane (Polydimethylsiloxane, PDMS), the thickness of the film is 0.1-1 mm, and the height of the pump cavity 33 is 10-100 microns.

Embodiment 2

[0021] The structure of the pump body of Embodiment 2 is shown in Figure 5. The difference between this embodiment and the first embodiment is that the miniature taper valve between the pump chamber and the liquid inlet and outlet can be two taper pipes arranged side by side 52, 54 , It can also be used in parallel for multiple tapered tube valves, which can increase the flow rate.

Embodiment 3

[0022] The structure of the pump body of Embodiment 3 is shown in Figure 6. The difference between this embodiment and the first embodiment is that the micro-valve integrated on the film can be a circle with many pairs of wedges 66 arranged in a staggered manner on its inner wall. The number of wedge valves 62, 64 formed by tubes and wedges 66 can be 1 row of 4, 2 rows of 4, 3 rows of 6, 4 rows of 8, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com