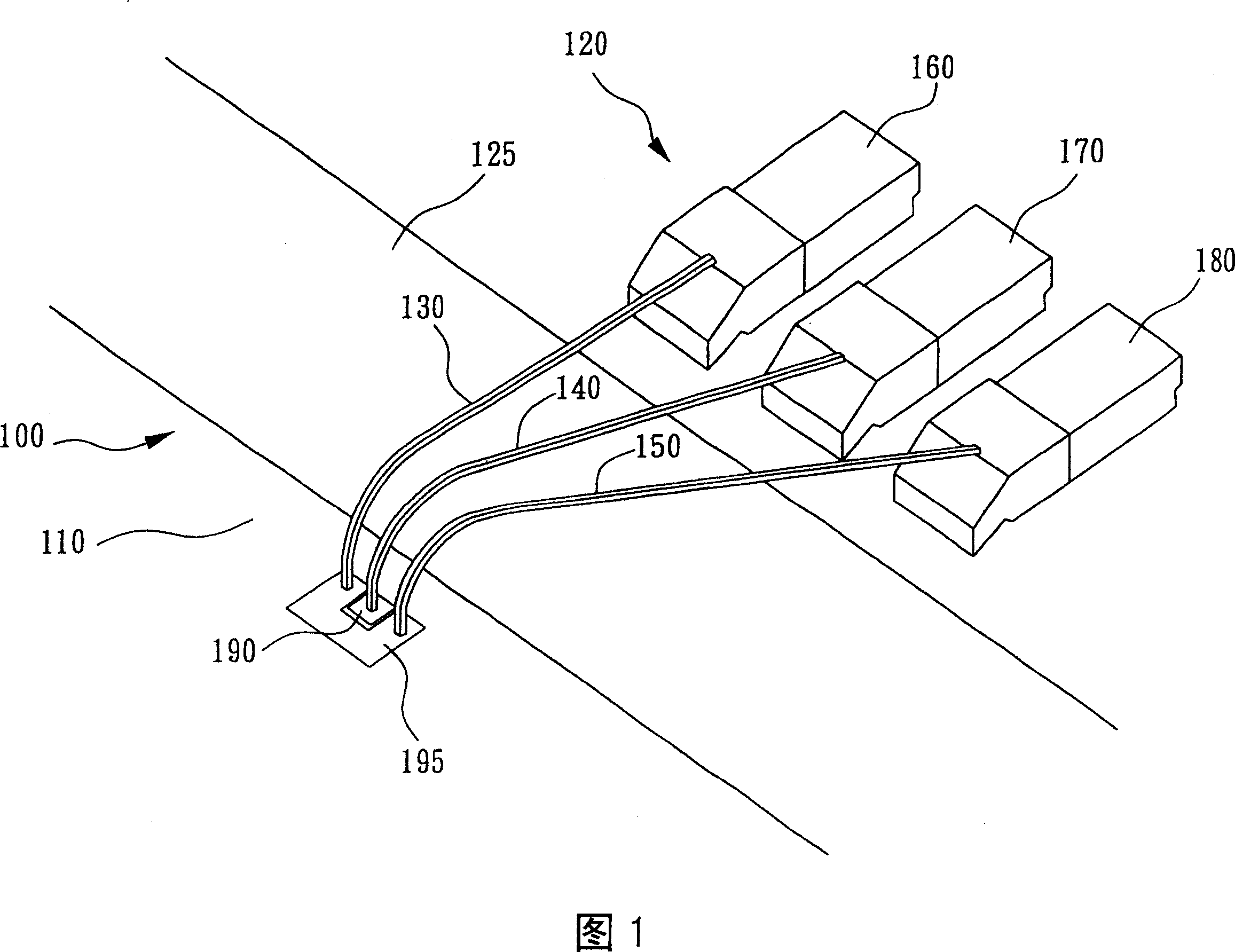

High-frequency IC multi-bus knot tying structure and method

A technology of integrated circuit and wire structure, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems affecting circuit characteristics, large electromagnetic interference, and increased metal wire spacing, so as to reduce insertion loss, increase return loss, and improve The effect of high frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

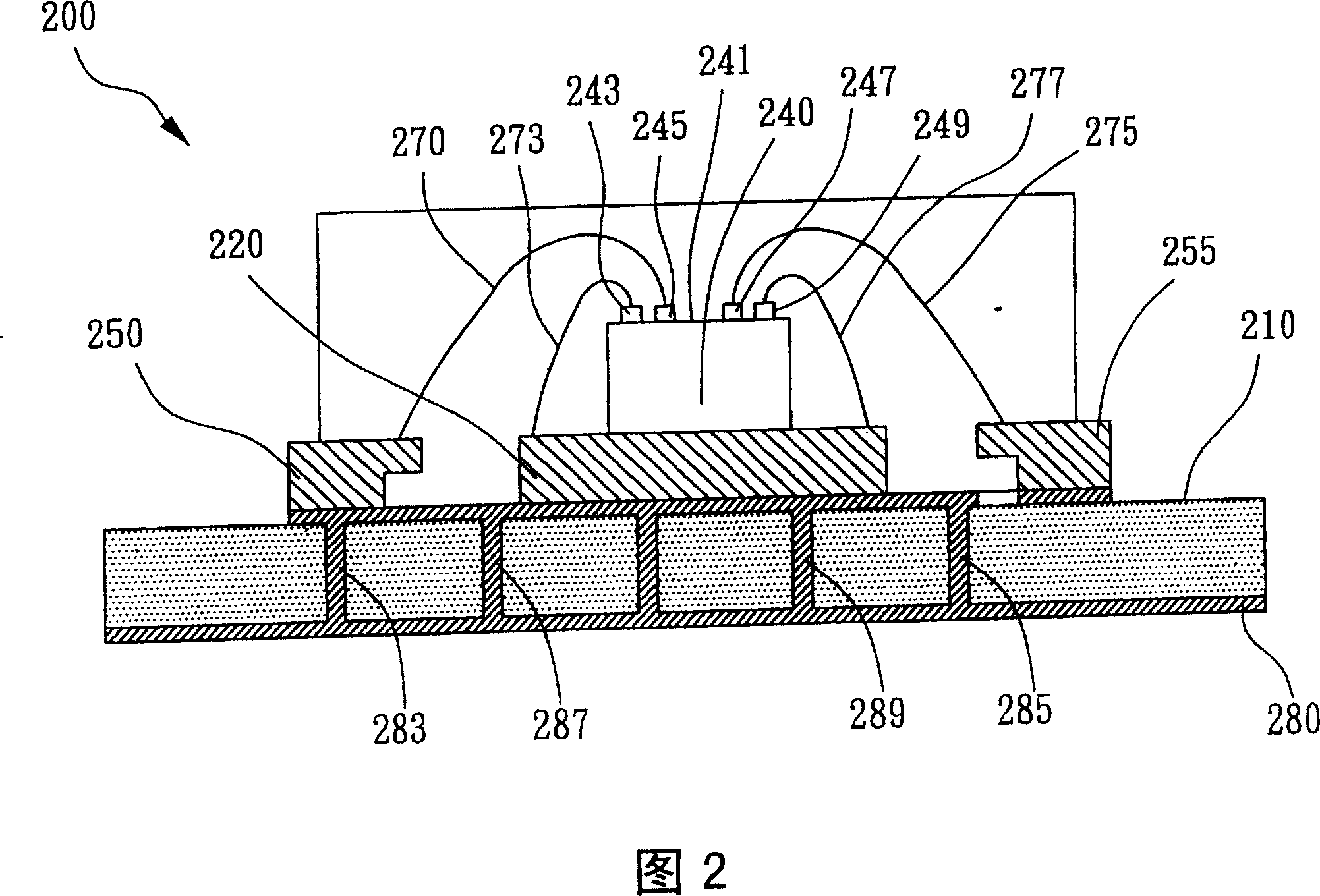

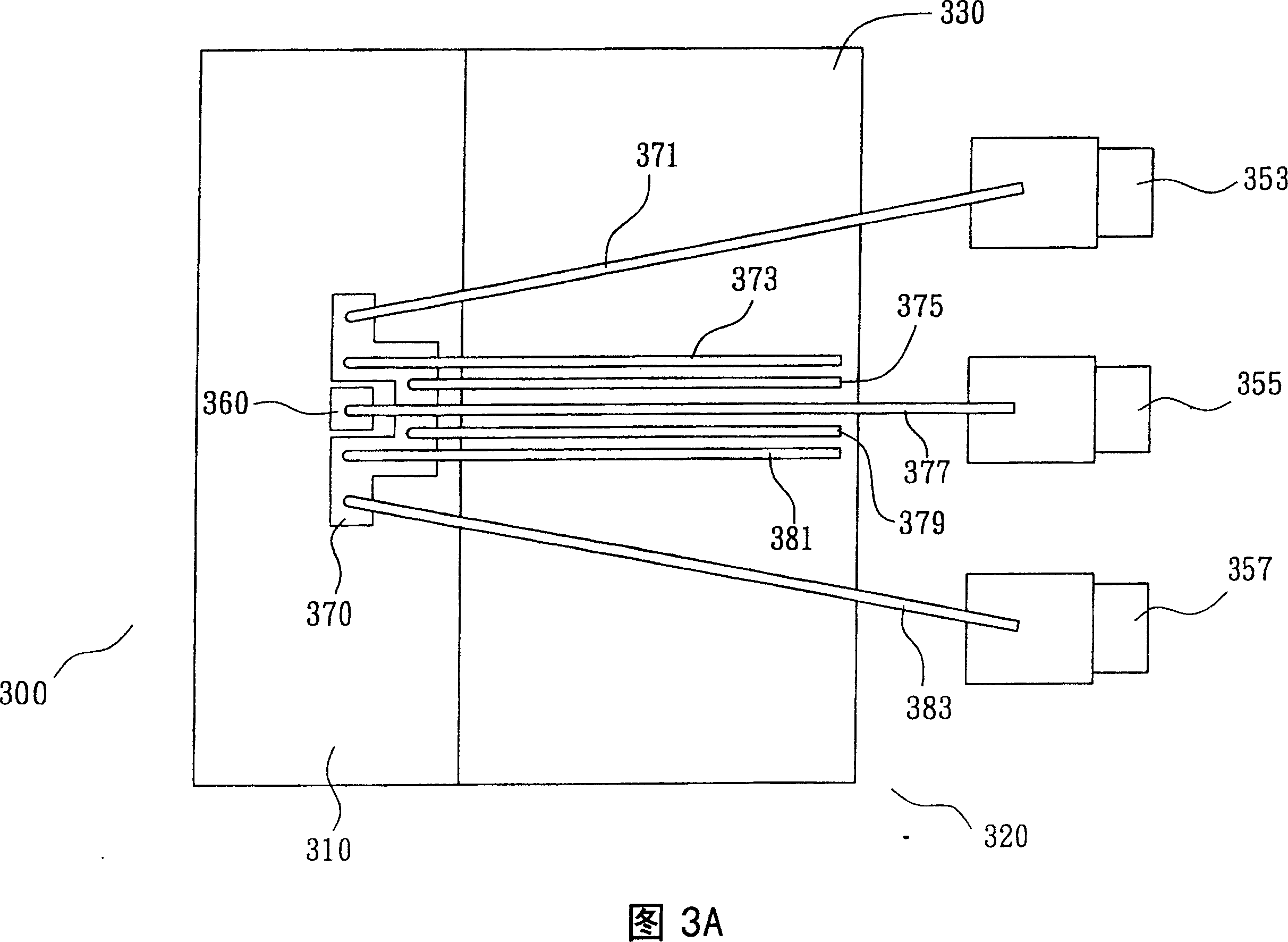

[0024] In order to have a further cognition and understanding of the features, purposes and functions of the present invention, the detailed description is as follows in conjunction with the accompanying drawings:

[0025] In view of the defects such as large parasitic capacitance, inductance and relatively large electromagnetic interference that the known wire bonding structure can produce, the present invention considers not only using the coplanar wire pad on the IC chip, but also considering the use of the coplanar wire pad on the coplanar wire pad. The ground wire is bonded on the chip pad under the chip to shorten the distance between the signal ground on the chip. The present invention also specially considers adding grounding metal wires on the coplanar bonding pads to be bonded to the chip pad, and makes a more perfect plan for the arrangement and distribution of the grounding metal wires, so as to effectively reduce the insertion loss between components and increase t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap