Combination type steel net frame and concrete composite block, and method of making same

A technology of combined section steel and composite components, which is applied in the direction of building components, building structure, thermal insulation, etc., to achieve the effects of reducing auxiliary projects, wide application, and improving engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

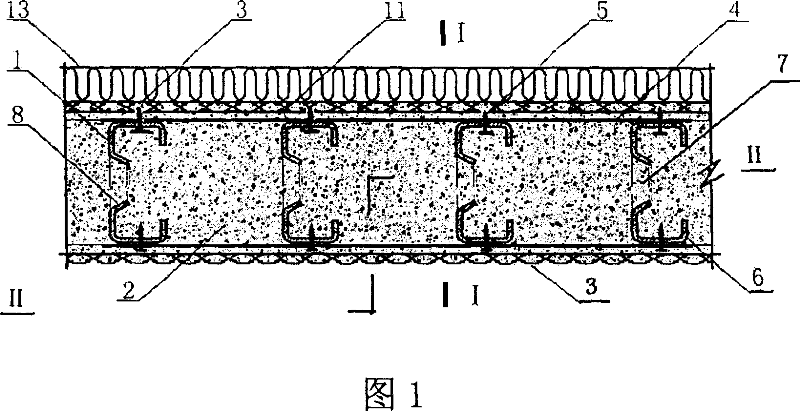

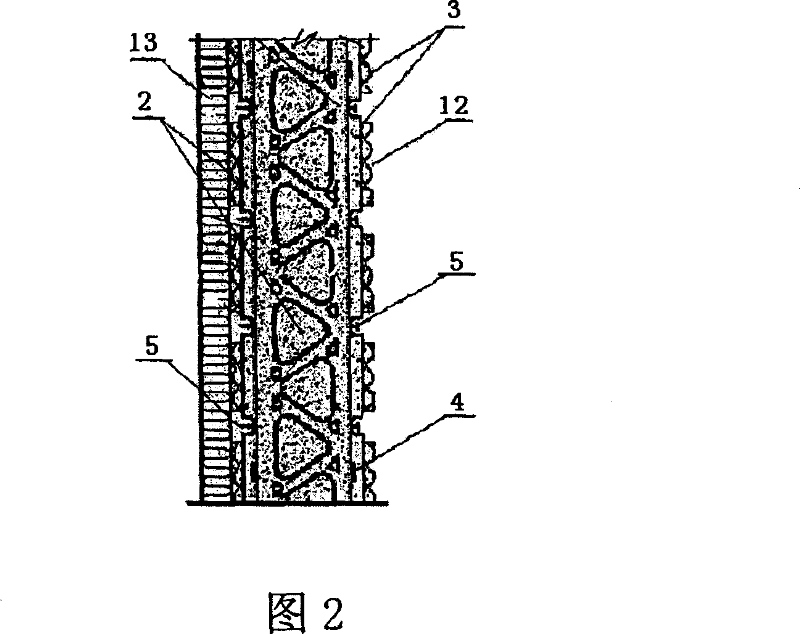

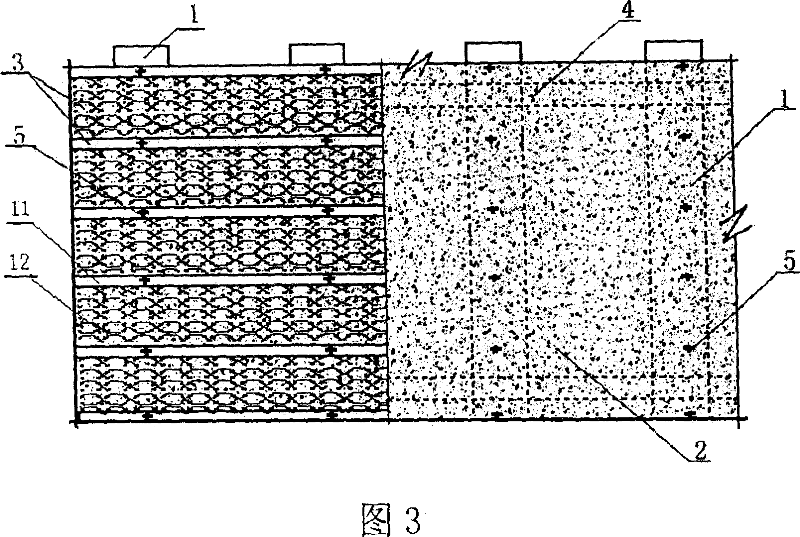

[0042] As shown in Figures 1, 2, 3, 4, 5, and 6, when the combined steel grid and concrete composite member of the present invention are used as a wall with an insulating layer, it includes cold-formed lattice steel 1, concrete 2, two The cold-formed lattice steel 1 above (shown as 4 cold-formed lattice steels, and the cross-sectional view of each cold-formed lattice steel 1 is the wing 8 of the steel) is fixed on the connector 4 on one side of the outer surface of the cold-formed lattice steel skeleton, and the steel mesh composite insulation board 13 is fixed on the other side; the concrete 2 is filled in the cold-formed lattice steel Inside the skeleton and in the gap between the steel skeleton of cold-formed lattice configuration and the composite thermal insulation board 13 of expanded metal, and concrete 2 is filled in the pores of the steel skeleton of cold-formed lattice configuration and expanded metal mesh 3 .

[0043] Connector 4 can be conventional steel materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com