A kind of method for uniform dispersion of high aromatic oil

A technology with high aromatics and oil uniformity, applied in the field of styrene-butadiene rubber production, can solve the problems of high consumption of additives and increased cost, and achieve the effect of reducing the cost of additives, speeding up the degree of dispersion, and simplifying the on-site process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

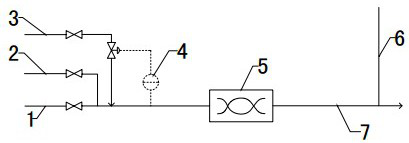

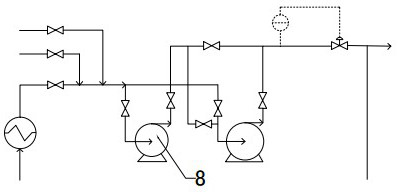

Image

Examples

Embodiment 1

[0026] 1) High aromatic oil and primary desalinated water are measured at a mass ratio of 1:0.95 for later use;

[0027] 2) Mix high-aromatic oil with primary desalted water accounting for 42% of the total primary desalted water, and then heat up to 150°C by bubbling steam;

[0028] 3) After the material enters the emulsifier and stirs for 7.5s, the temperature in the emulsifier is 140°C, and the remaining first-stage desalted water is added to the output pipeline for dilution. The high-aromatic oil is quickly and completely dispersed to form a stable emulsion.

Embodiment 2

[0030] 1) High-aromatic oil and primary desalinated water are measured at a mass ratio of 1:0.9 for later use;

[0031] 2) Mix high-aromatic oil with primary desalted water accounting for 40% of the total primary desalted water, and then heat up to 145°C by bubbling steam;

[0032] 3) After the material enters the emulsifier and stirs for 7 seconds, the temperature in the emulsifier is 150°C, and the remaining first-stage desalted water is added to the output pipeline for dilution. The high aromatic oil is quickly and completely dispersed to form a stable emulsion.

Embodiment 3

[0034] 1) High aromatic oil and primary desalted water are measured at a mass ratio of 1: 1.0 for later use;

[0035] 2) Mix high-aromatic oil with primary desalted water accounting for 45% of the total primary desalted water, and then heat up to 140°C by bubbling steam;

[0036] 3) After the material enters the emulsifier and stirs for 8 seconds, the temperature in the emulsifier is 130°C, and the remaining first-stage desalted water is added to the output pipeline for dilution. The high aromatic oil is quickly and completely dispersed to form a stable emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com