Prepn process of nanometer spinel type ferrite powder

A nano-spinel and spinel-type technology is applied in the field of preparation of nano-spinel-type ferrite powder, and can solve the problem that the spinel-type ferrite has a complicated process and cannot obtain homogeneous ferrite. The problem of uneven structure and particle size distribution can achieve the effect of regular crystal shape, uniform size and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

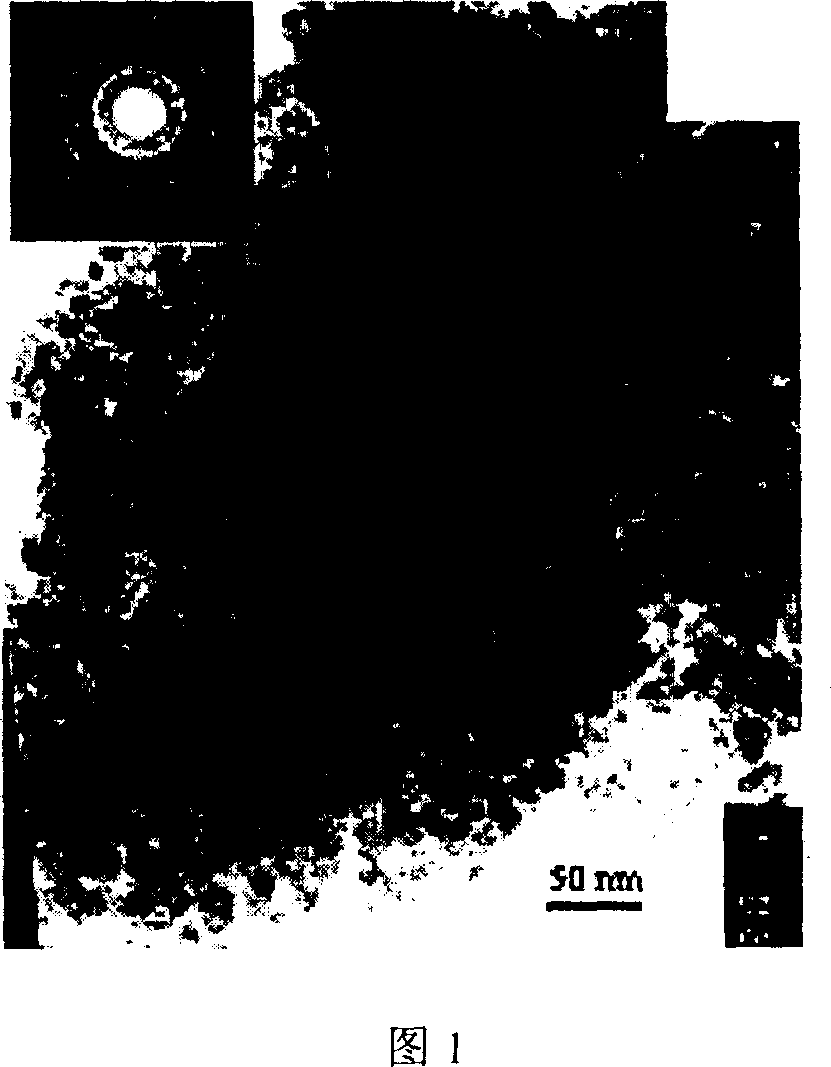

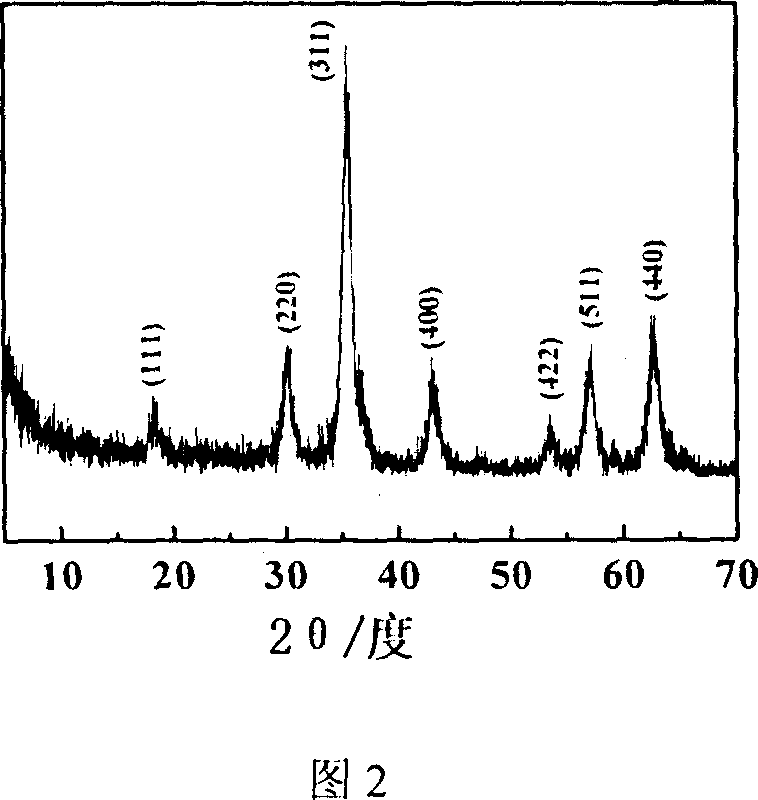

[0031] Embodiment 1, preparation homogeneous nanometer CoFe 2 o 4 Ferrite powder:

[0032] 1) Dissolving 4 parts by weight of acrylic acid in 1 part by weight of deionized water, fully dissolved under magnetic stirring, to obtain solution A;

[0033] 2) Fix the molar ratio of iron (III) nitrate and acrylic acid in solution A to be 1:20, weigh cobalt (II) and iron (III) nitrate in molar ratio of 1:2, add to solution A, and A homogeneous system B is obtained under stirring;

[0034] 3) The deionized aqueous solution of ammonium persulfate that is 2wt% by weight is slowly added in the homogeneous system B that step 2) makes under the condition of magnetic stirring, obtains solution C; The added ammonium persulfate and step 1 ) in the weight ratio of acrylic acid is 0.01:1;

[0035] 4) Heat the C solution obtained in step 3) at 100°C for 1 hour to complete the polymerization of the system; then dry it at 80°C for 24 hours; grind it after cooling, then place it in a muffle furn...

Embodiment 2

[0038] Embodiment 2, preparation homogeneous nanometer MnFe 2 o 4 Ferrite powder:

[0039] 1) Dissolving 2 parts by weight of acrylic acid in 1 part by weight of deionized water, fully dissolved under magnetic stirring, to obtain solution A;

[0040] 2) Fix the molar ratio of ferric (III) chloride to acrylic acid in solution A to be 1:20, weigh manganese (II) and ferric chloride (III) in molar ratio of 1:2, add them to solution A, Obtain homogeneous system B under magnetic stirring;

[0041] 3) The deionized aqueous solution of 6wt% ammonium persulfate is slowly added to the homogeneous system B prepared in step 2) under the condition of magnetic stirring to obtain solution C; the added ammonium persulfate and step 1 ) in a weight ratio of acrylic acid of 0.05:1;

[0042] 4) Heat the C solution obtained in step 3) at 60°C for 2 hours to complete the polymerization of the system; then dry it at 75°C for 24 hours; grind it after cooling, and then place it in a muffle furnace...

Embodiment 3

[0044] Embodiment 3, preparation homogeneous nano-NiFe 2 o 4 Ferrite powder:

[0045] 1) Dissolving 1 part by weight of acrylic acid in 1 part by weight of deionized water and fully dissolving it under magnetic stirring to obtain solution A;

[0046]2) Fix the molar ratio of iron (III) sulfate and acrylic acid in solution A to be 1:20, weigh nickel (II) and iron (III) sulfate in molar ratio of 1:2, add them to solution A, and A homogeneous system B is obtained under stirring;

[0047] 3) The deionized aqueous solution of ammonium persulfate that is 8wt% is slowly added to the homogeneous system B prepared in step 2) under the condition of magnetic stirring to obtain solution C; the added ammonium persulfate and step 1 ) in the weight ratio of acrylic acid is 0.1:1;

[0048] 4) Heat the C solution obtained in step 3) at 80°C for 3 hours to complete the polymerization of the system; then dry it at 75°C for 24 hours; grind it after cooling, and then place it in a muffle furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com