New processing method for spinning ramee

A processing method and technology of ramie, applied in spinning machines, yarns, textiles and papermaking, etc., can solve the problems of processing and product quality, and achieve a small footprint, high fiber length uniformity, and less fiber damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

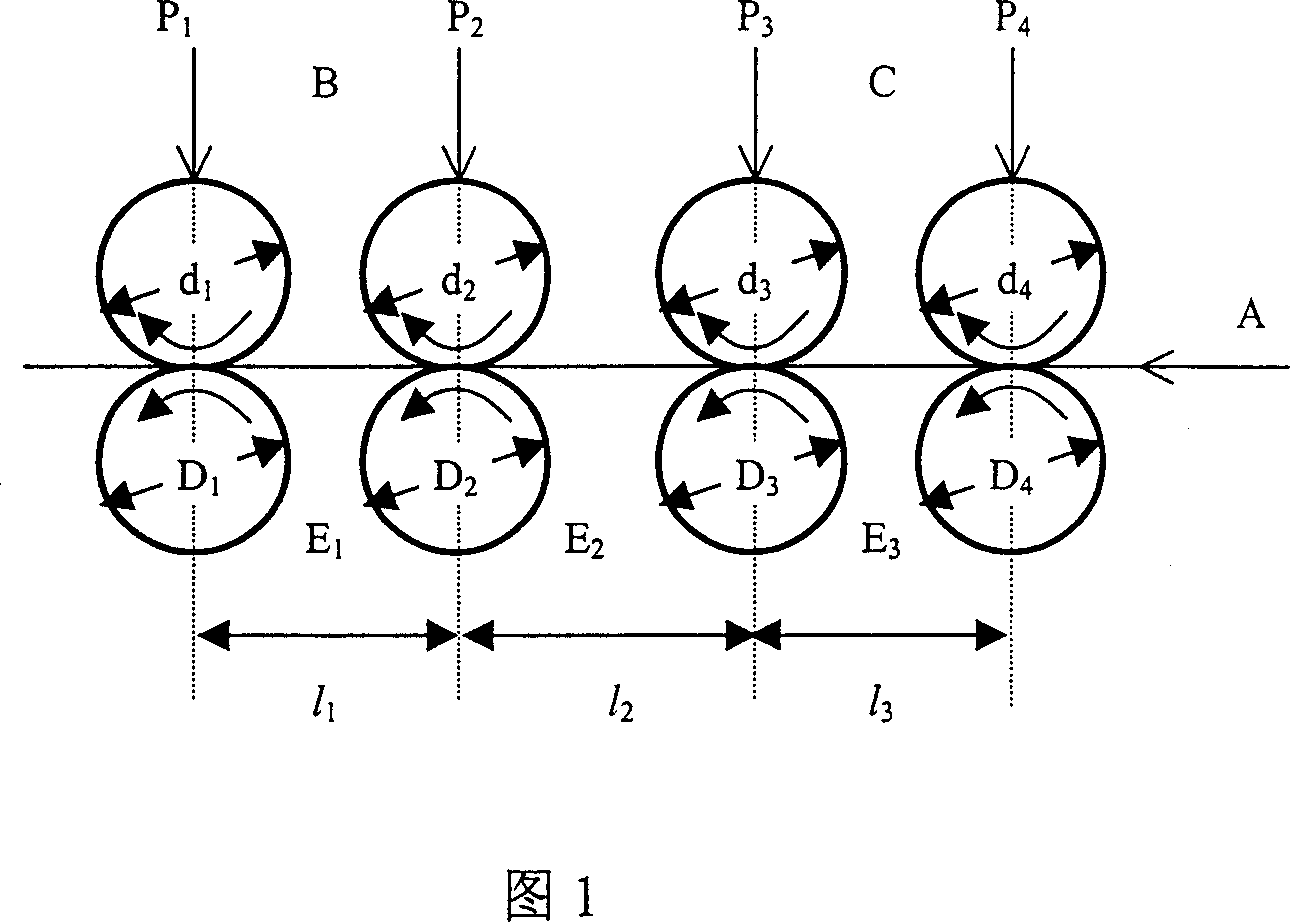

Image

Examples

Embodiment

[0030]The ramie refined hemp produced in Hunan is adopted, and its properties are shown in Table 1:

[0031] average length

[0032] After adopting the stretch-cut spinning technique of the present invention to above-mentioned lean hemp raw material to process, the quality performance index of its semi-finished product and finished product is as shown in table 2 and table 3:

[0033] average

[0034] It can be seen from Table 1 that although the strength of the fiber after stretch cutting has decreased, the unevenness of the strength has been improved to a certain extent, and the elongation of the fiber has remained basically unchanged, especially the content of ultra-long fibers above 150mm has decreased significantly, and the content of long fibers above 250mm has decreased significantly. has been eliminated;

[0035] intensity

[0036] The above experimental results show that: after adopting the stretch-cutting process, since the ultra-lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com