Method for eliminating static electricity of metal conducting layer to complete etching

A metal conductive layer and etching technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of incomplete etching and wafer process yield decline, and achieve the effect of completely improving etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

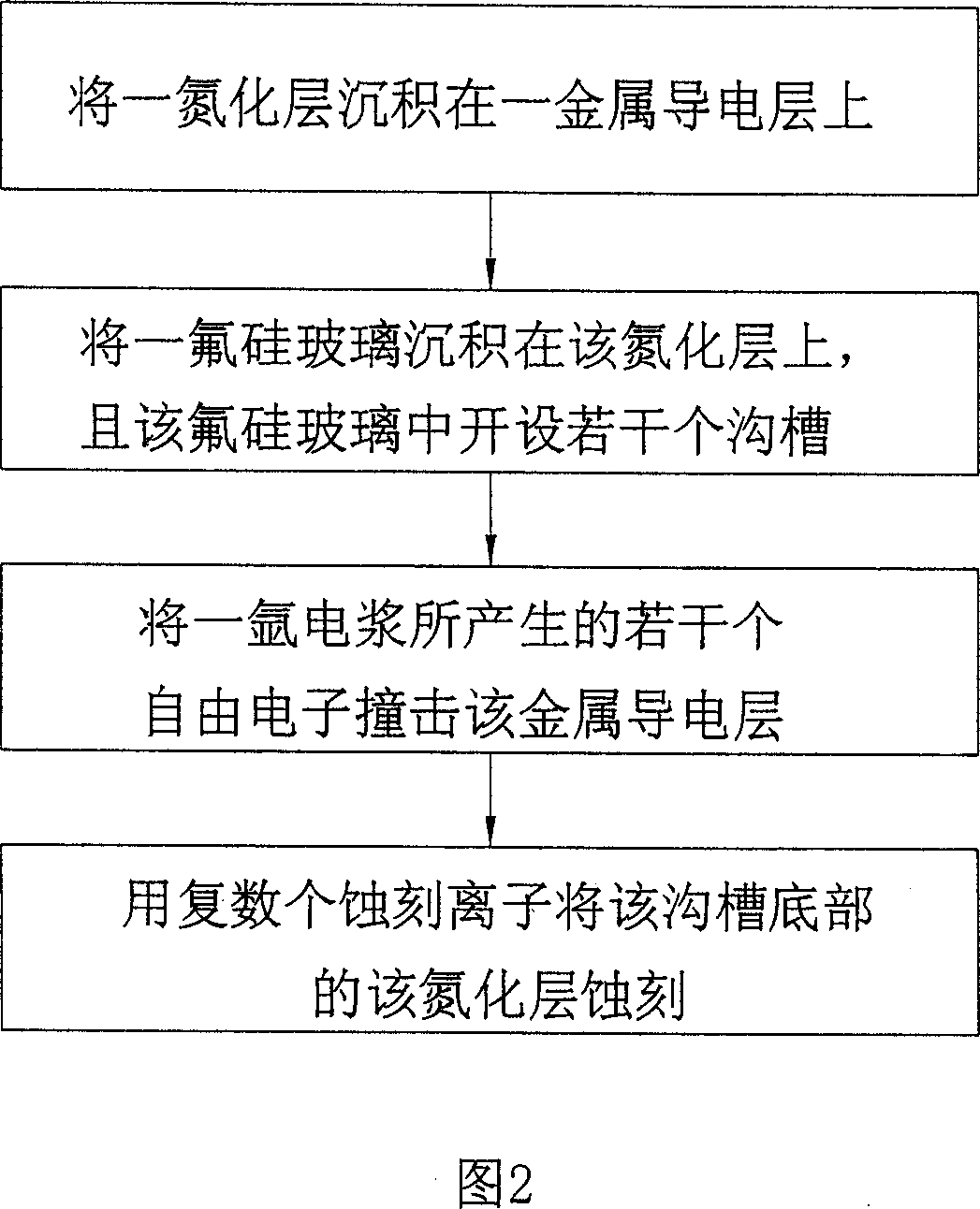

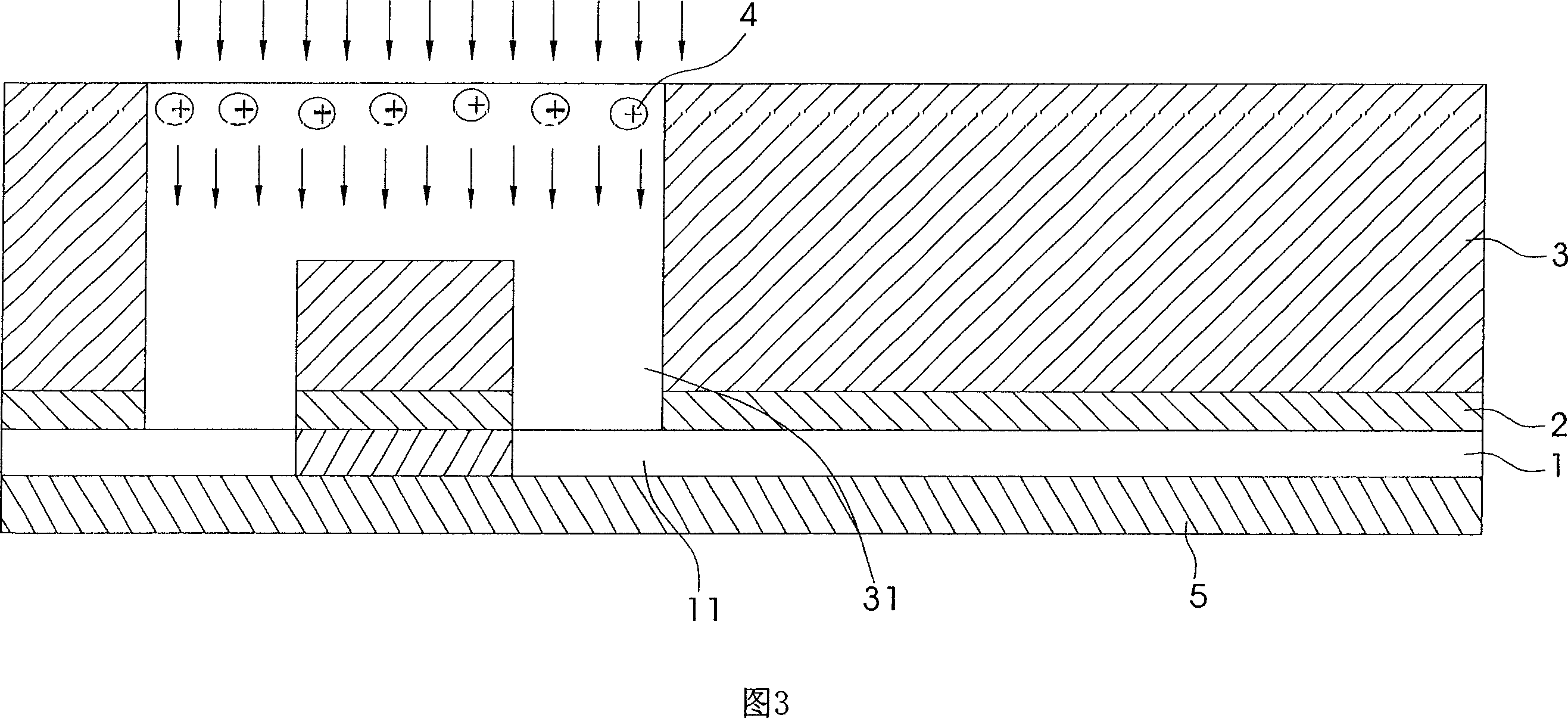

[0025] The present invention eliminates the static electricity of metal conduction layer and makes the method for etching completely, and its step (as shown in Figure 2) comprises: a. a metal conduction layer 1 (as copper layer) is deposited on an oxide layer 5, then a nitrogen An oxide layer 2 (such as a silicon nitride layer) is deposited on the metal conductive layer 1;

[0026] b. A fluorosilicate glass 3 is deposited on the nitrided layer 2, and several round holes or grooves 31 are opened on the fluorosilicate glass 3, and the bottom of the round holes or grooves 31 is the nitrided layer. Layer 2;

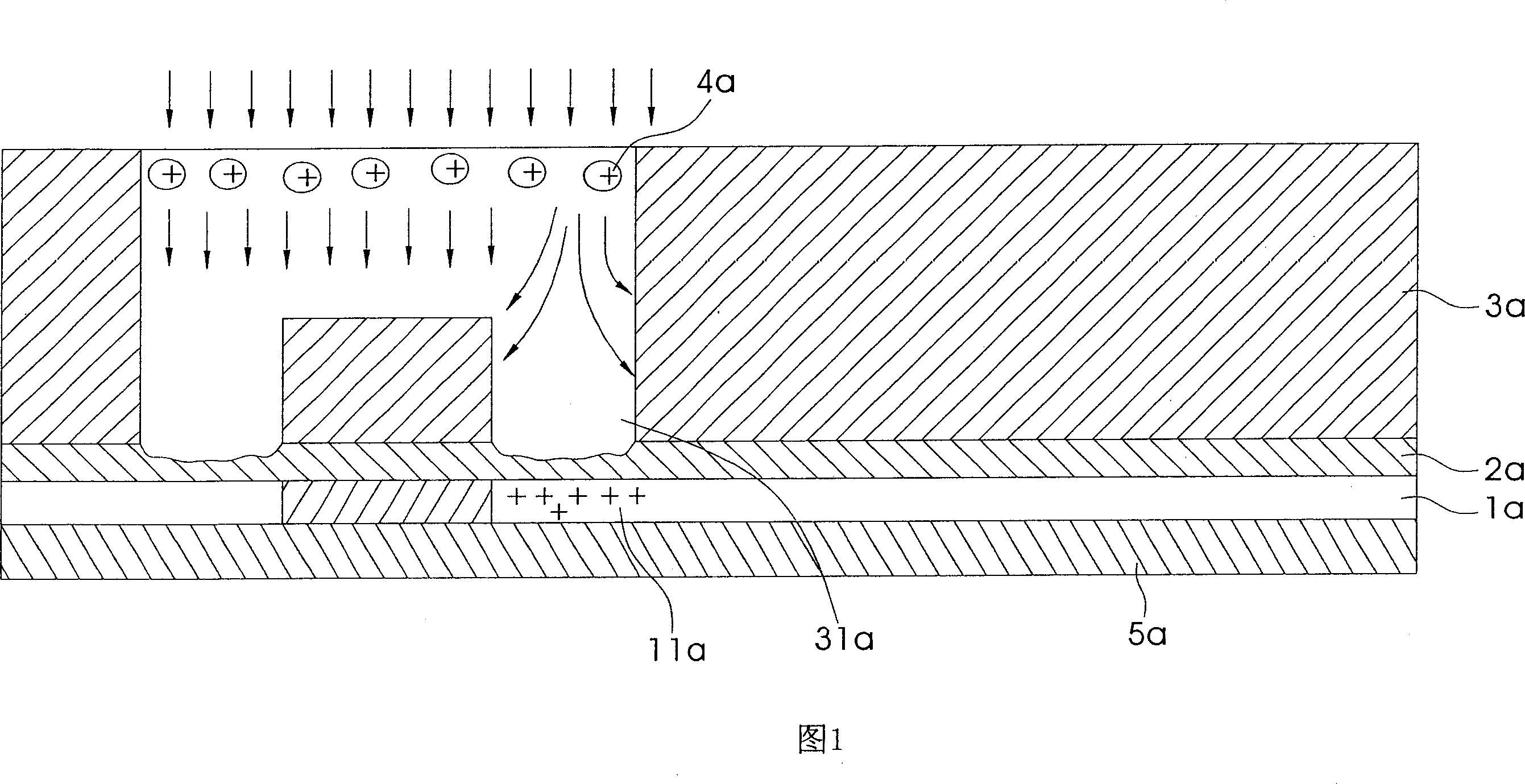

[0027] c. A number of free electrons generated by a high-pressure low-density plasma are bumped into the metal conductive layer 1 to neutralize a positively charged static electricity 11 on the metal conductive layer 1, so that the metal conductive layer 1 has an electric charge be neutral or have a number of negatively charged free electrons; and

[0028] d. Etching the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com