Flexible ultra-thin electrophoresis display screen and method for making same

A display screen and electrophoresis technology, applied in nonlinear optics, static indicators, instruments, etc., can solve problems such as difficulty in completion, complex manufacturing process and process, impact on yield, performance cost reduction, etc., to achieve improved bendability, The effect of thickness reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

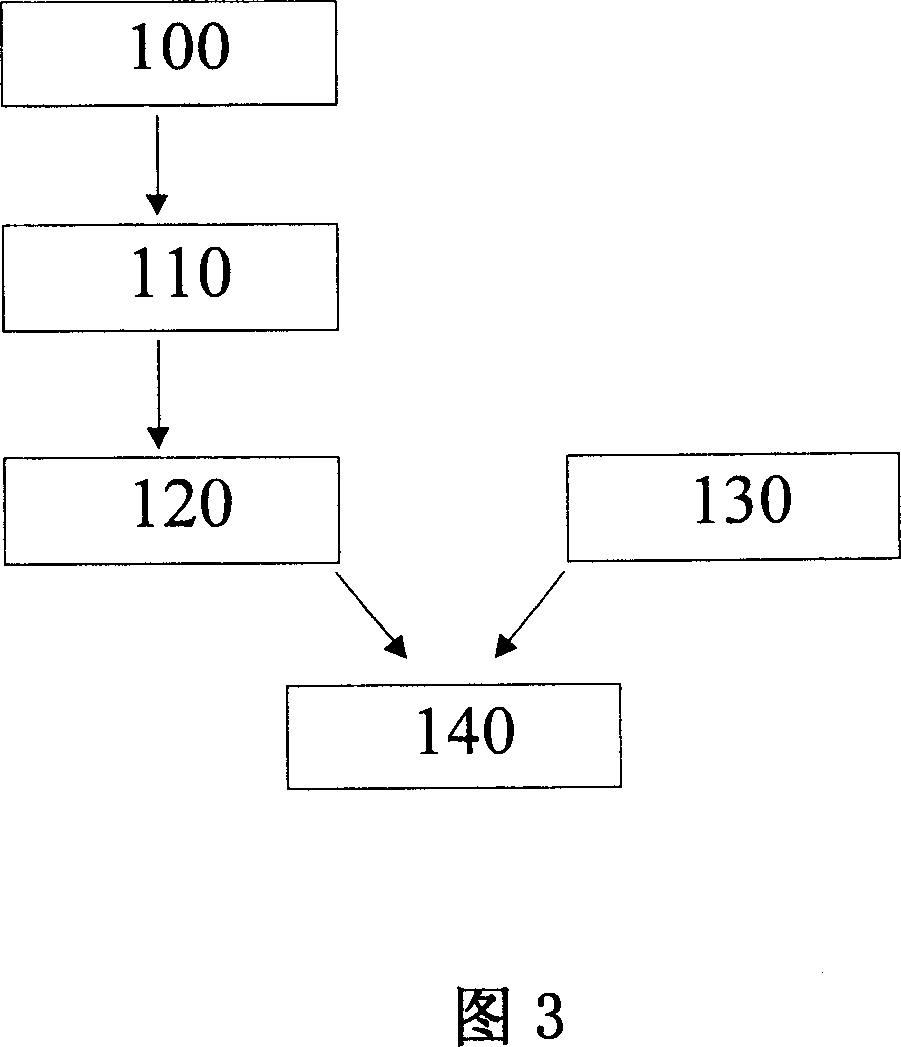

[0050] The preparation method of the plastic-based electrophoretic display screen of the embodiment of the present invention is shown in Figure 3, including the following steps:

[0051] During the continuous production of the upper display layer in rolls, the display material is coated in blocks and continuous sheets on the transparent conductive film substrate with a barrier layer to form a display material layer, step 100;

[0052] Continuously coating a layer of nanocomposite adhesive layer on the display material layer to form an upper display layer, step 110;

[0053] Cutting a block-shaped upper layer display layer along the seam of the transparent conductive film substrate with a barrier layer between the material display layers, step 120;

[0054] Using a stainless steel film or a plastic film with a barrier layer as a substrate, using polymer thick film technology to make a dielectric layer and a conductive layer of the circuit to form a lower layer control circuit, ...

no. 2 example

[0069] The preparation method of the plastic-based electrophoretic display screen in this embodiment is basically the same as that of the first embodiment, except for the preparation method of the adhesive material and the structure of the lower control circuit.

[0070] The adhesive layer nanocomposite used in this example is prepared by in-situ synthesis (in-situpolymerization). The adhesive layer in Example 1 directly utilizes pre-synthesized polymers. Starting from monomers, nano-inorganic substances are added during the synthesis of polymer materials. In the adhesive layer prepared in this way, the nano-inorganic substances are more evenly distributed in the polymer substrate, so that the barrier performance of the adhesive layer to water and oxygen can be improved more. A variety of polymer synthesis methods can be used here, such as stepwise addition polymerization, free radical polymerization and ion polymerization. Polymers that can be made into adhesives include pol...

no. 3 example

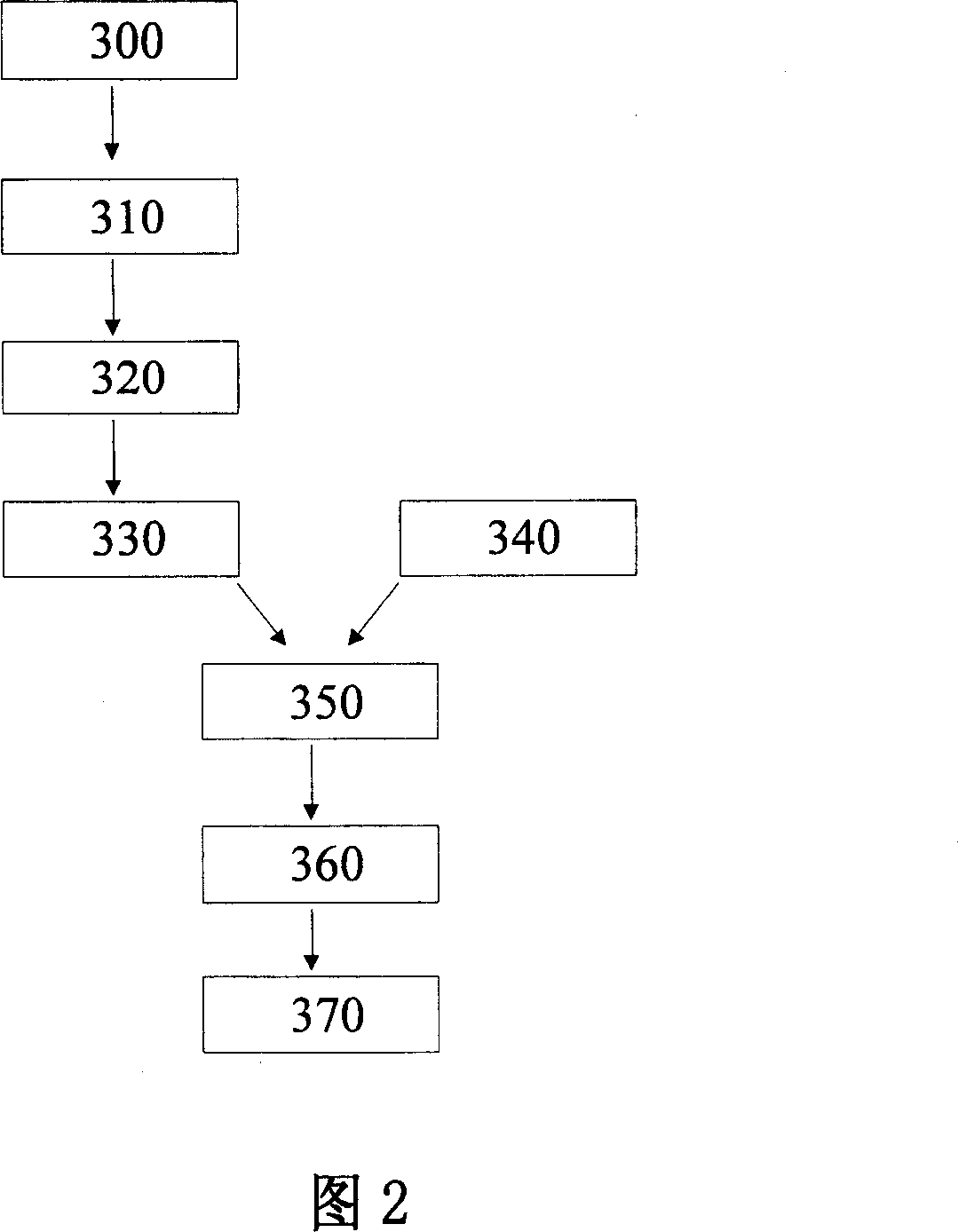

[0076] The preparation method of the plastic-based electrophoretic display screen in this embodiment is shown in Figure 13, including the following steps:

[0077] During the continuous production of the upper display layer in rolls, the display material is obliquely coated on a transparent conductive film substrate with a barrier layer to form a block display material layer, step 200;

[0078] Continuously coating a layer of nanocomposite adhesive layer on the display material layer to form an upper display layer, step 210;

[0079] Cutting the block-shaped upper layer display layer along the seam of the transparent conductive film substrate with a barrier layer between the material display layers, step 220;

[0080] Using a stainless steel film or a plastic film with a barrier layer as a substrate, using vacuum deposition technology to make a dielectric layer and a conductive layer of the circuit to form a lower layer control circuit, step 230;

[0081] Combining the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com