Shape memory alloy and its preparation method

A memory alloy and alloy element technology, applied in zirconium, niobium, aluminum-based shape memory alloys and their preparation, and titanium fields, can solve the problems of increased production costs, metal toxicity, poor processing performance, and poor processing performance. Shape memory recovery function, high non-toxicity to human body, high plasticity effect of cold working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a shape memory alloy is characterized in that the alloy element components are smelted into a solid metal and subjected to 50%-99% cold working deformation and material modification through solid solution and aging.

[0024] The solution heat treatment temperature is: 600°C-900°C, the time is: 20 minutes-120 minutes, the sample size is 1mm 3 Keep warm within 20 seconds; aging temperature: 150°C-360°C, time: 30 minutes-180 minutes, sample 1mm 3 Keep warm within 20 seconds.

Embodiment

[0025] Embodiment: (corresponding to Fig. 1-Fig. 10)

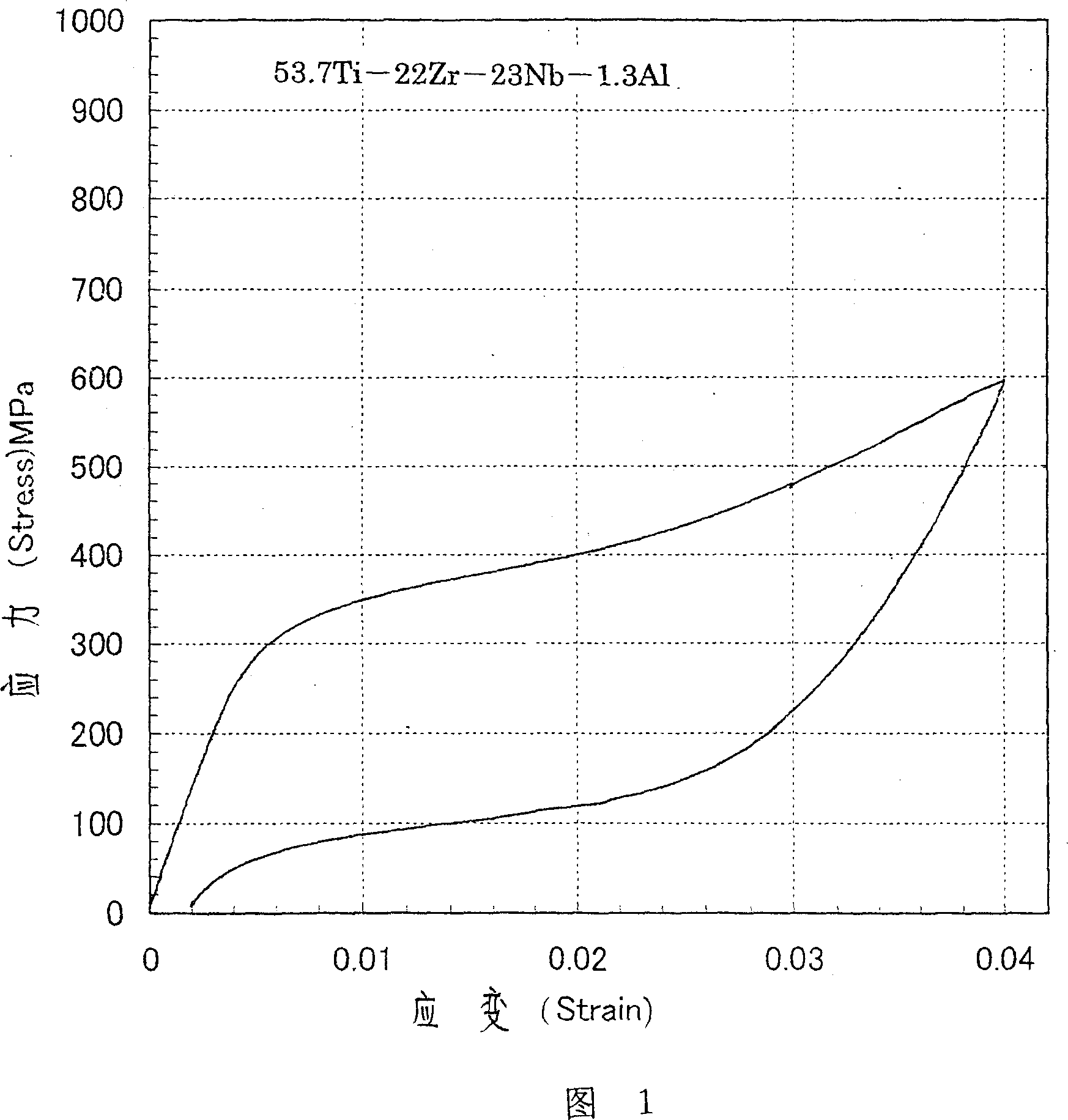

[0026] (1) The content of each component is: 53.7Ti-22Zr-23Nb-1.3Al;

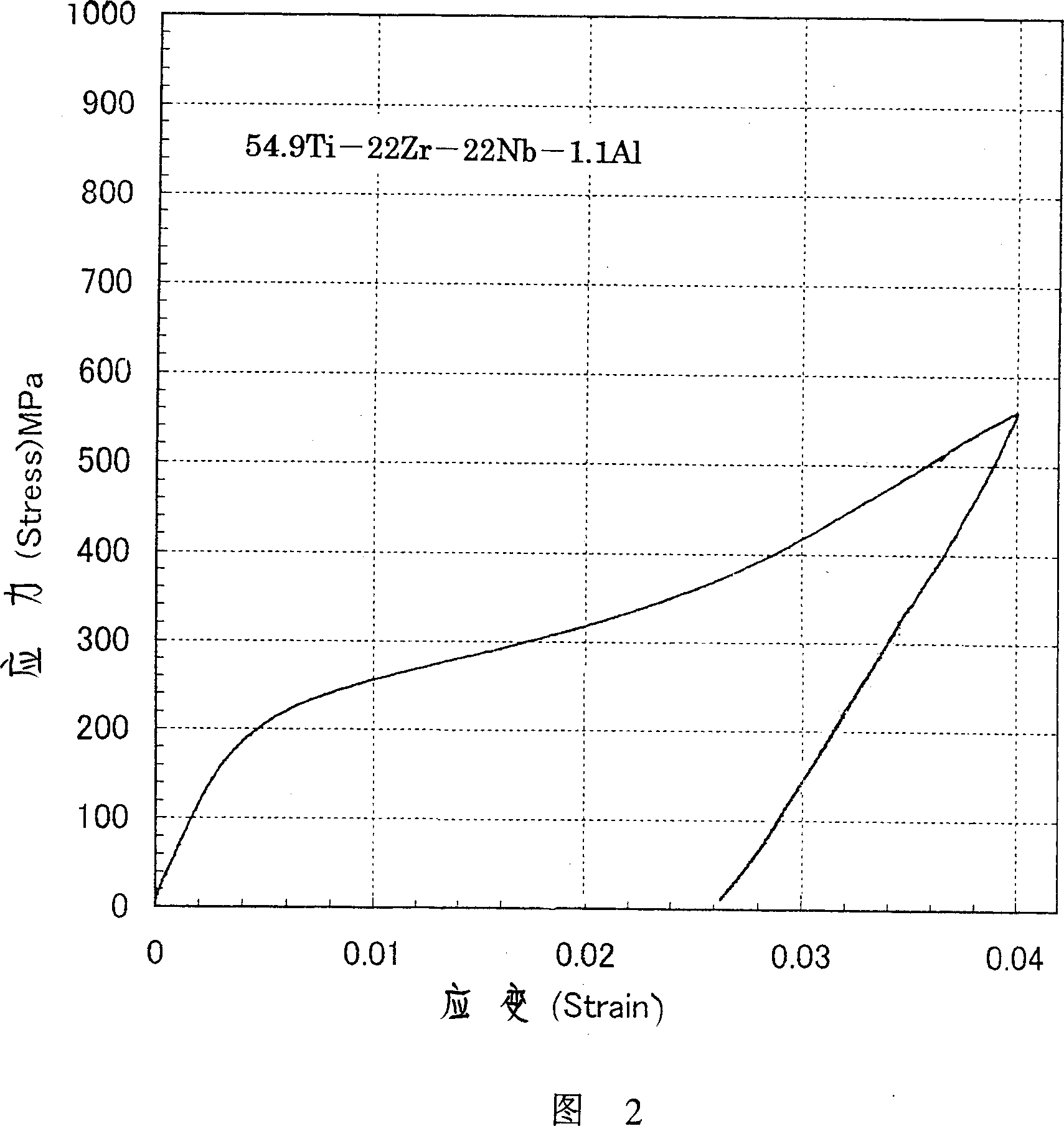

[0027] (2) The content of each component is: 54.9Ti-22Zr-22Nb-1.1Al;

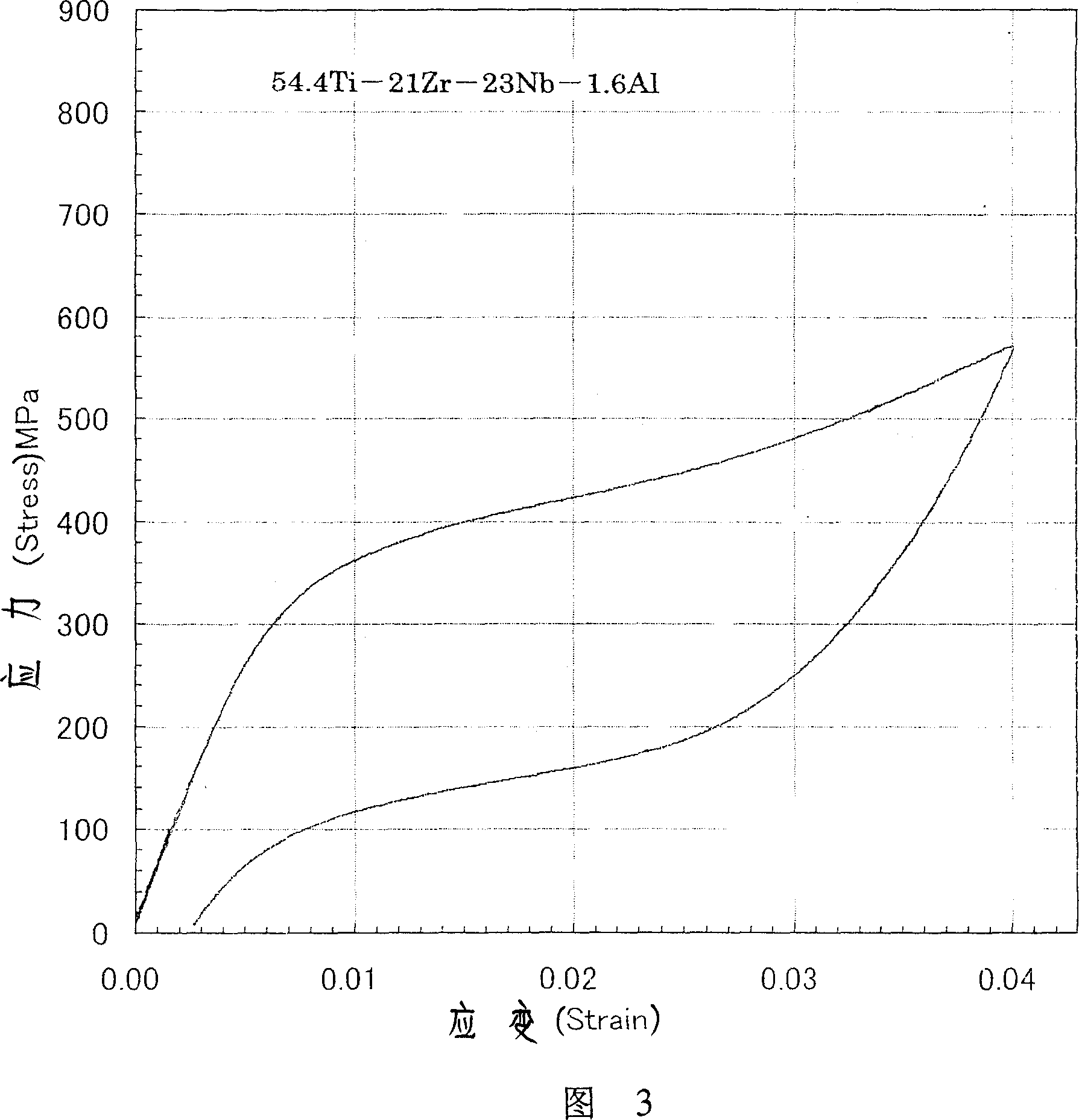

[0028] (3) The content of each component is: 54.4Ti-21Zr-23Nb-1.6Al;

[0029] (4) The content of each component is: 51.1Ti-23Zr-24Nb-1.9Al;

[0030] (5) The content of each component is: 54.2Ti-22.1Zr-22Nb-1.7Al;

[0031] (6) The content of each component is: 55.1Ti-23Zr-20Nb-1.9Al;

[0032] (7) The content of each component is: 54.9Ti-22Zr-22Nb-1.1Al,

[0033] Temperature 200°C, time 60 minutes;

[0034] (8) The content of each component is: 53.7Ti-22Zr-23Nb-1.3Al,

[0035] Temperature 320°C, time 60 minutes;

[0036] (9) The content of each component is: 54.5Ti-22Zr-22Nb-0.2Mo-1.3Al;

[0037] (10) The content of each component is: 54.6Ti-22Zr-22Nb-0.1Cr-1.3Al.

[0038] Among the above-mentioned constituent elements, Ti, the main component, has the following characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com