A kind of manganese titanate nanometer material is used as the purposes of imitating enzyme active material

A manganese titanate nanometer and nanomaterial technology, applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve problems such as insufficient killing ability of cancer cells, and achieve the effects of excellent ablation ability, easy large-scale preparation, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Step (1): Mix 1.25mmol n-tetrabutyl titanate with 16mL ethylene glycol and stir to form solution A; mix 1.25mmol manganese sulfate monohydrate with 4mL ethylenediamine and stir to form solution B; Under stirring, the above solution A and solution B are completely mixed to form solution C;

[0079] Step (2): Slowly add 5mL of ultrapure water dropwise to the above solution C under vigorous stirring, then transfer it to a 50mL stainless steel autoclave with a polytetrafluoroethylene liner, and react at 200°C for 24h After that, cool down to room temperature naturally. The product was collected by centrifugation and washed several times with ethanol and water to remove impurities. Finally, a light yellow powder is obtained by drying in a vacuum oven, which is two-dimensional manganese titanate nanosheets.

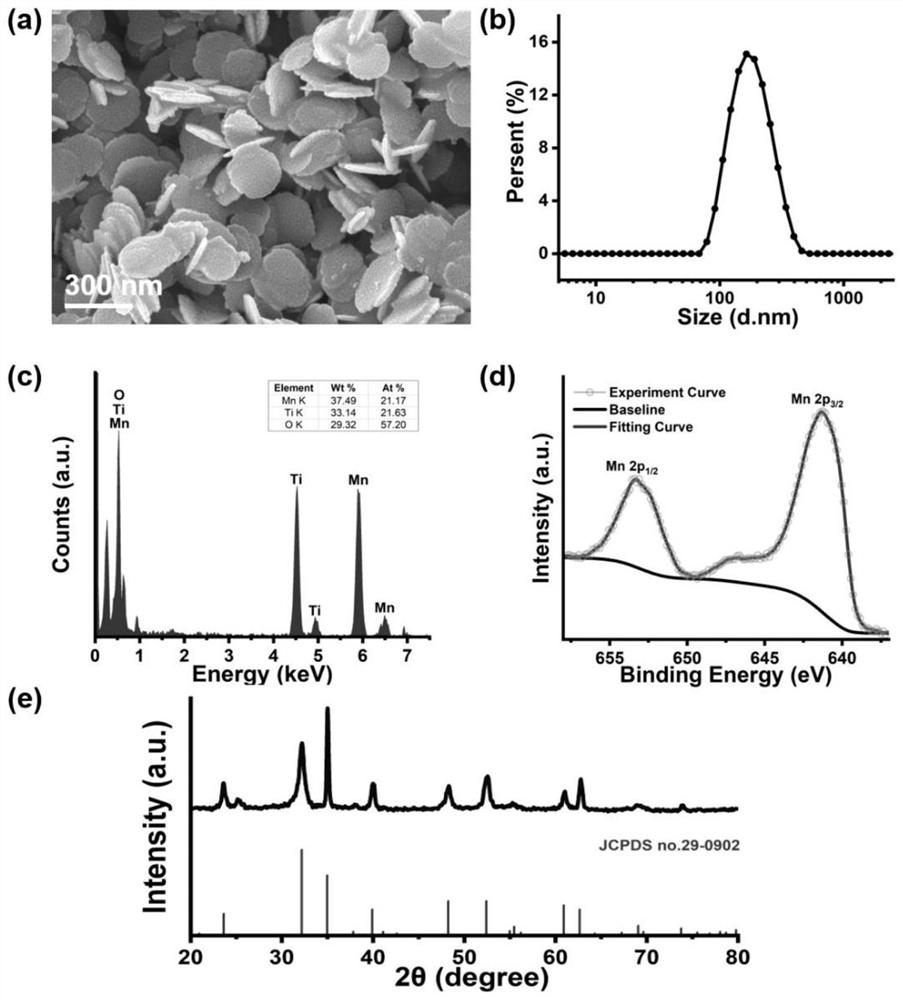

[0080] figure 1 It is the various basic characterization diagrams of the two-dimensional manganese titanate nanosheets prepared through the steps of Example 1.

[00...

Embodiment 2

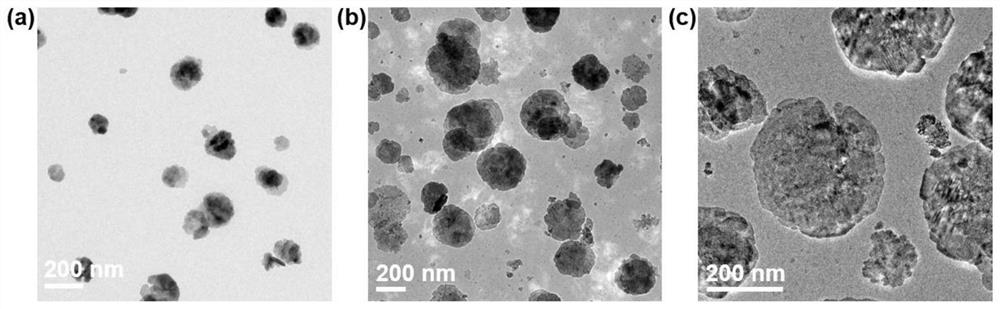

[0087] Compared with Example 1, the main difference is that the solvothermal temperature is 150° C., and the solvothermal time is 18 hours (the solvothermal temperature is reduced, and the solvothermal time is reduced).

[0088] Step (1): Mix 1.25mmol n-tetrabutyl titanate with 16mL ethylene glycol and stir to form solution A; mix 1.25mmol manganese sulfate monohydrate with 4mL ethylenediamine and stir to form solution B; Under stirring, the above solution A and solution B are completely mixed to form solution C;

[0089] Step (2): Slowly add 5mL of ultrapure water dropwise to the above solution C under vigorous stirring, then transfer it to a 50mL stainless steel autoclave with a polytetrafluoroethylene liner, and react at 150°C for 18h After that, cool down to room temperature naturally. The product was collected by centrifugation and washed several times with ethanol and water to remove impurities. Finally, a light yellow powder is obtained by drying in a vacuum oven, whi...

Embodiment 3

[0091] Compared with Example 1, the main difference is that the solvothermal temperature is 250° C., and the solvothermal time is 30 h (the solvothermal temperature increases and the solvothermal time increases).

[0092] Step (1): Mix 1.25mmol n-tetrabutyl titanate with 16mL ethylene glycol and stir to form solution A; mix 1.25mmol manganese sulfate monohydrate with 4mL ethylenediamine and stir to form solution B; Under stirring, the above solution A and solution B are completely mixed to form solution C;

[0093] Step (2): Slowly add 5mL of ultrapure water dropwise to the above solution C under vigorous stirring, then transfer it to a 50mL stainless steel autoclave with a polytetrafluoroethylene liner, and react at 250°C for 30h After that, cool down to room temperature naturally. The product was collected by centrifugation and washed several times with ethanol and water to remove impurities. Finally, a light yellow powder is obtained by drying in a vacuum oven, which is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com