Titanium alloy for dental implant and preparation method thereof

A technology of dental implants and titanium alloys, applied in dental preparations, dental prostheses, dentistry, etc., can solve problems such as harm to the human body, reduce cell adaptability, etc., achieve good corrosion resistance, good biological adaptability, and solve cell adaptation. low sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

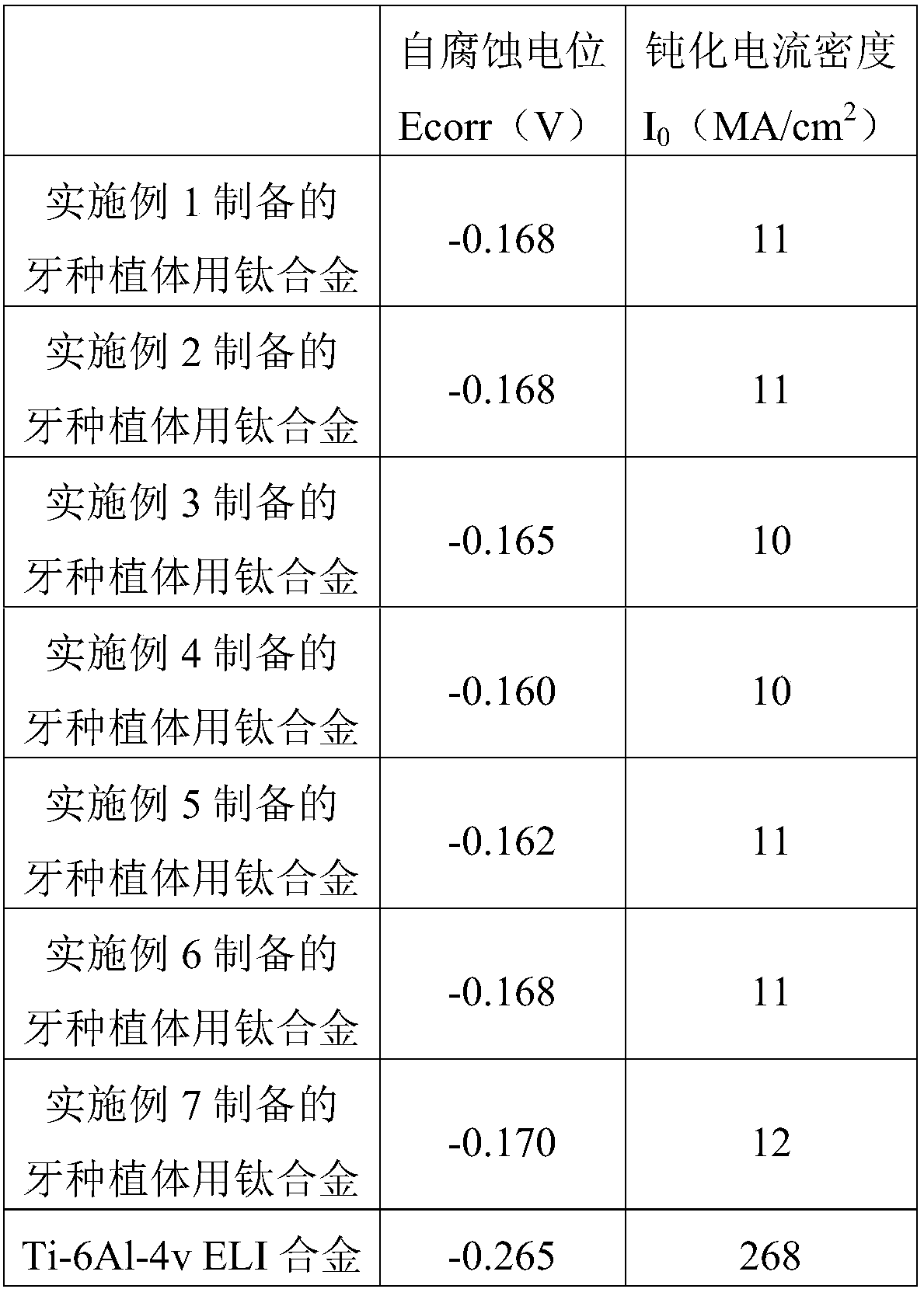

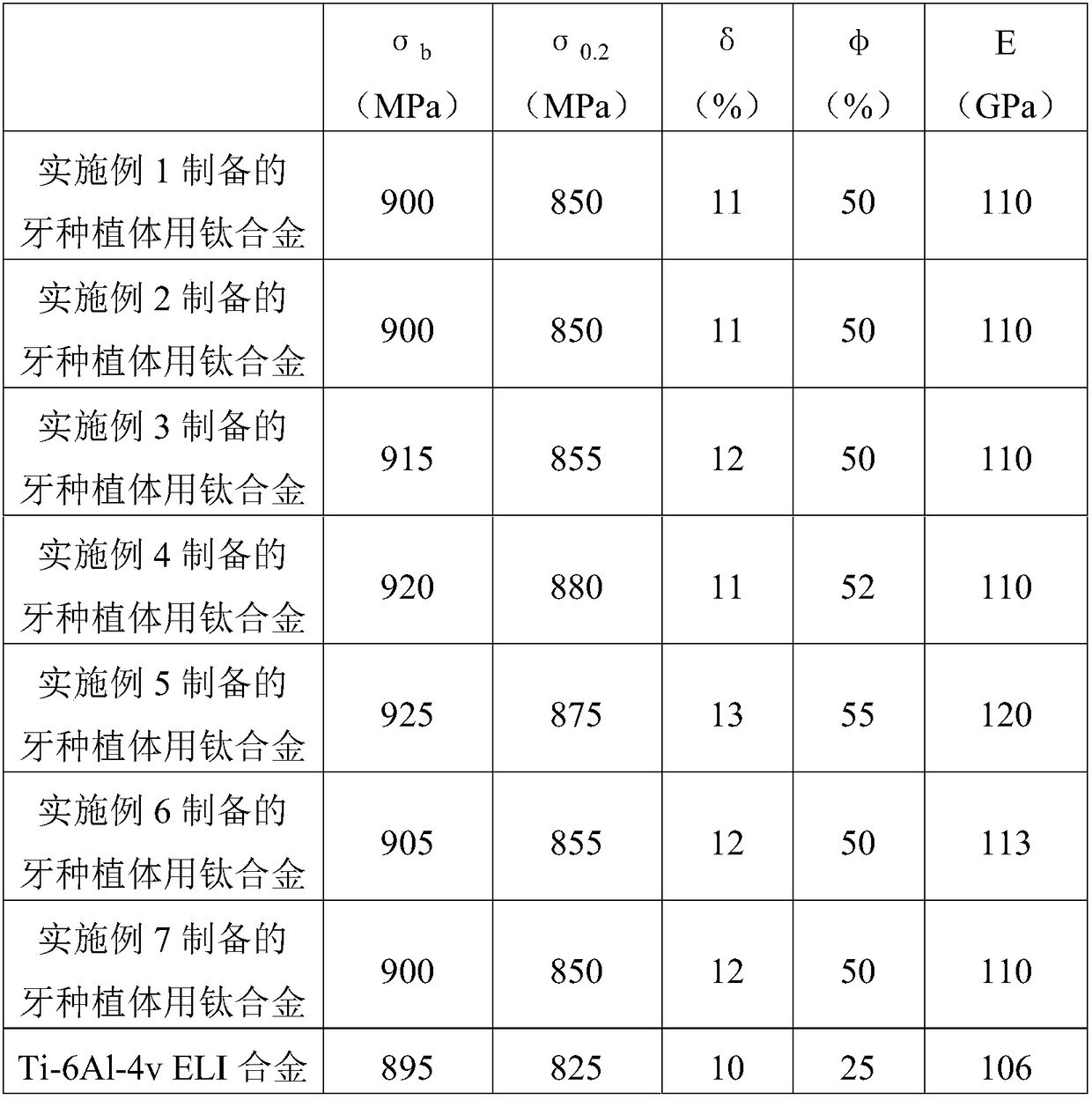

Examples

Embodiment 1

[0021] A preparation method of a titanium alloy for a dental implant, the preparation method comprising:

[0022] According to the percentage by weight, take 3% niobium, 10% zirconium and 87% titanium, after pressing the electrode, carry out secondary vacuum arc self-consumption smelting, cast the ingot at 950-1020 ° C, and process it into a dental implant at 850-900 ° C With titanium alloy, the total variation is controlled to be 65-95%, and the above-mentioned processing technology can be carried out according to the method of the prior art.

Embodiment 2

[0024] A preparation method of a titanium alloy for a dental implant, the preparation method comprising:

[0025] According to the percentage by weight, take 3.5% niobium, 7% zirconium and 89.5% titanium, after pressing the electrode, carry out secondary vacuum arc self-consumption melting, ingot casting at 950-1020 ° C, and 850-900 ° C for processing into dental implants With titanium alloy, the total variation is controlled to be 65-95%, and the above-mentioned processing technology can be carried out according to the method of the prior art.

Embodiment 3

[0027] A preparation method of a titanium alloy for a dental implant, the preparation method comprising:

[0028] According to the percentage by weight, take 4% niobium, 10% zirconium and 86% titanium, after pressing the electrode, carry out secondary vacuum arc self-consumption smelting, casting the ingot at 950-1020 ° C, and processing it into a dental implant at 850-900 ° C With titanium alloy, the total variation is controlled to be 65-95%, and the above-mentioned processing technology can be carried out according to the method of the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com