Composite conductive conduit bus-bar connector

A technology of composite conduction and busbar connection, which is applied in the direction of cable joints and permanent deformation, and can solve the problems that the busbar connection of insulating conductive pipes cannot be shielded and insulated, the surface of the connection is uneven, and it is unfavorable for safe operation. Achieve the effect of easy shielding and insulation treatment, smooth surface, and high current transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

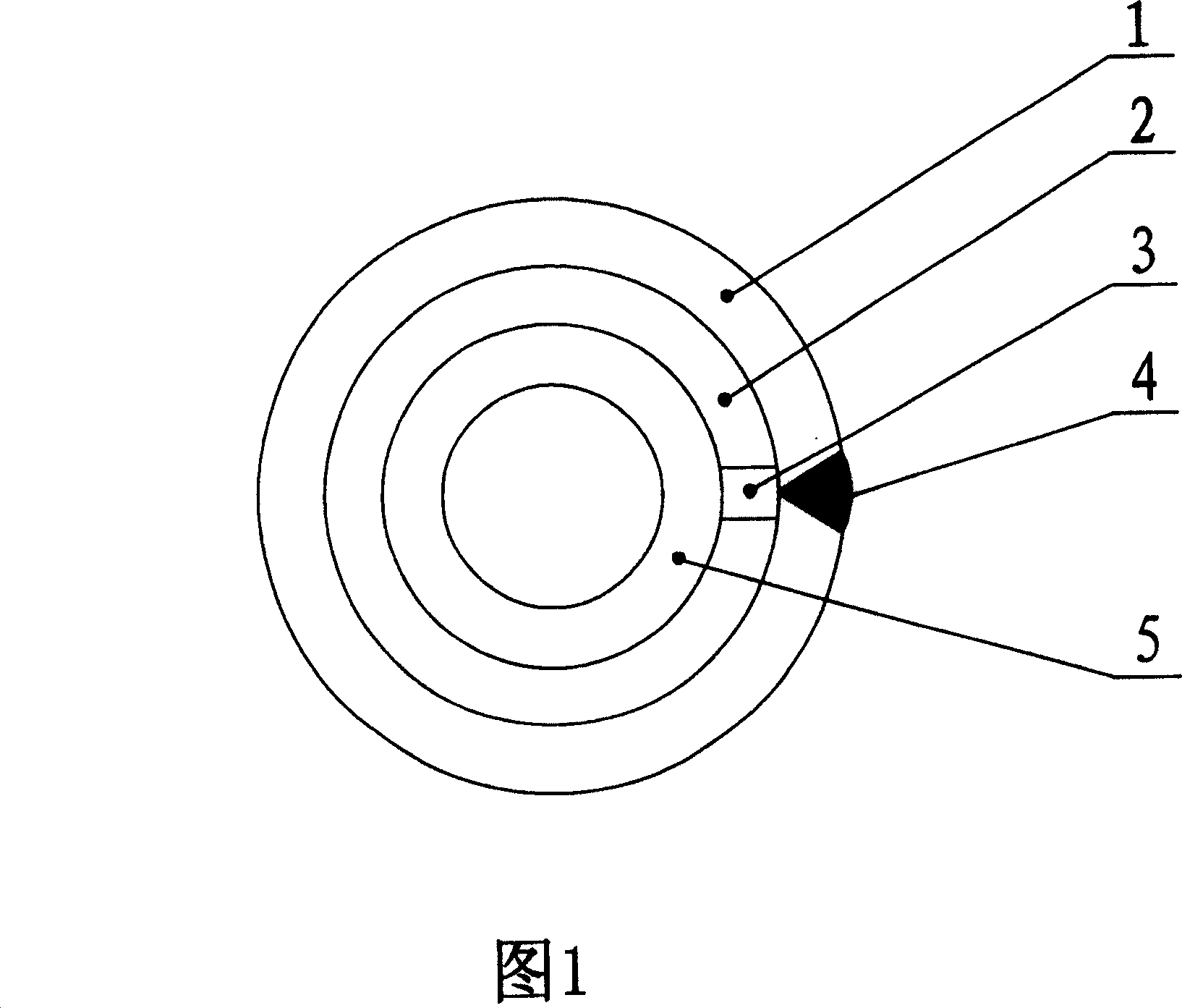

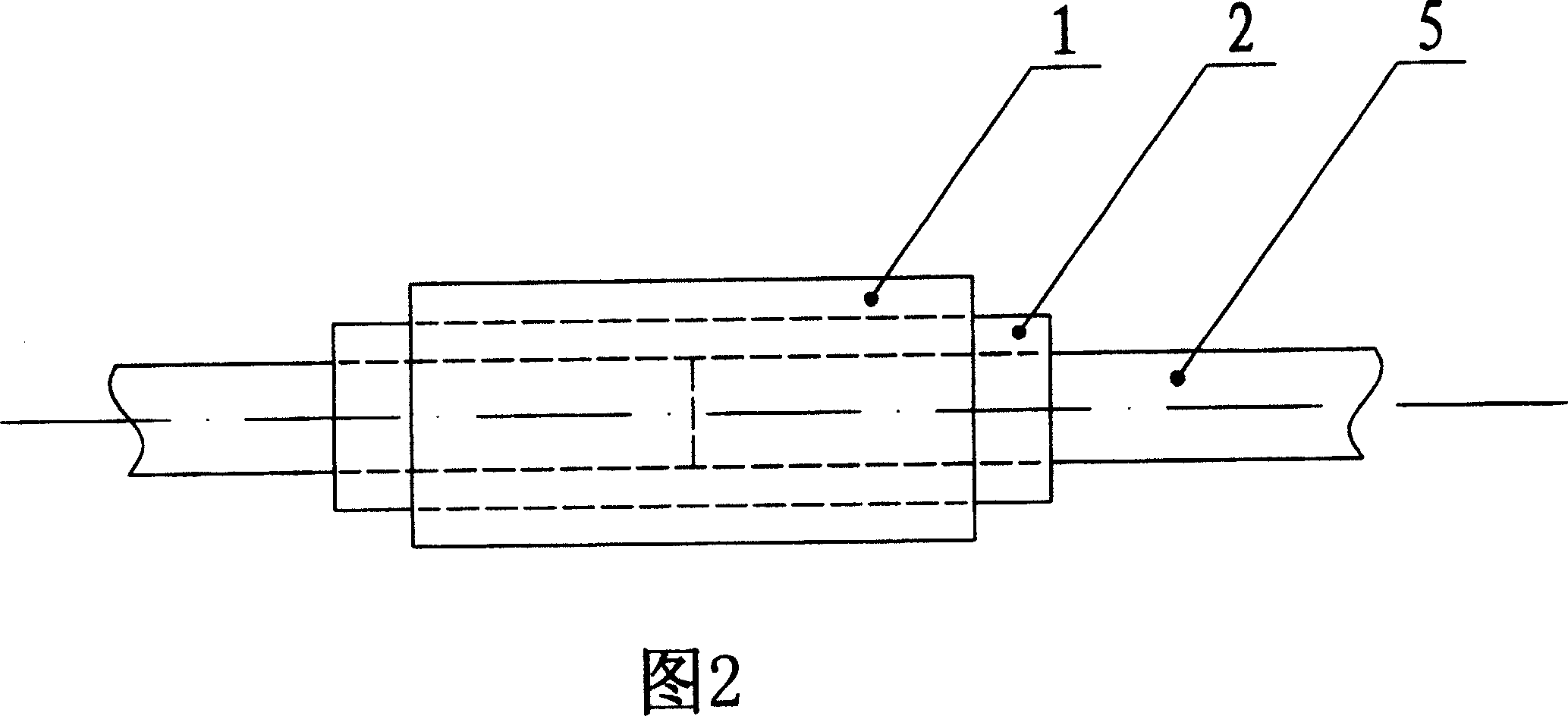

[0012] In the figure 1. Non-magnetic opening stainless steel sleeve, 2. Opening conductive metal sleeve, 3. Opening conductive metal sleeve opening, 4. Non-magnetic opening stainless steel sleeve welding port, 5. Insulated conductive pipe busbar. A composite conductive pipe busbar connector matching the outer diameter of the conductor of the insulating conductive pipe busbar 5 is inserted into the connecting portion of the insulating conductive pipe busbar 5 . The opening conductive metal sleeve 2 matching the outer diameter of the insulating conductive pipe bus 5 is inserted into the connecting part of the insulating conductive pipe bus 5; the material of the open conductive metal sleeve 2 can be the same as the material of the insulating conductive pipe bus 5; The surface of the cover 2 is inserted into the non-magnetic open stainless steel cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com