Reliability screening method of infrared focus planardetector

An infrared focal plane and screening method technology, applied in the field of electrical welding reliability screening, can solve problems such as welding performance failure, In bump fatigue damage, etc., and achieve the effects of improving accuracy, avoiding interference, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings:

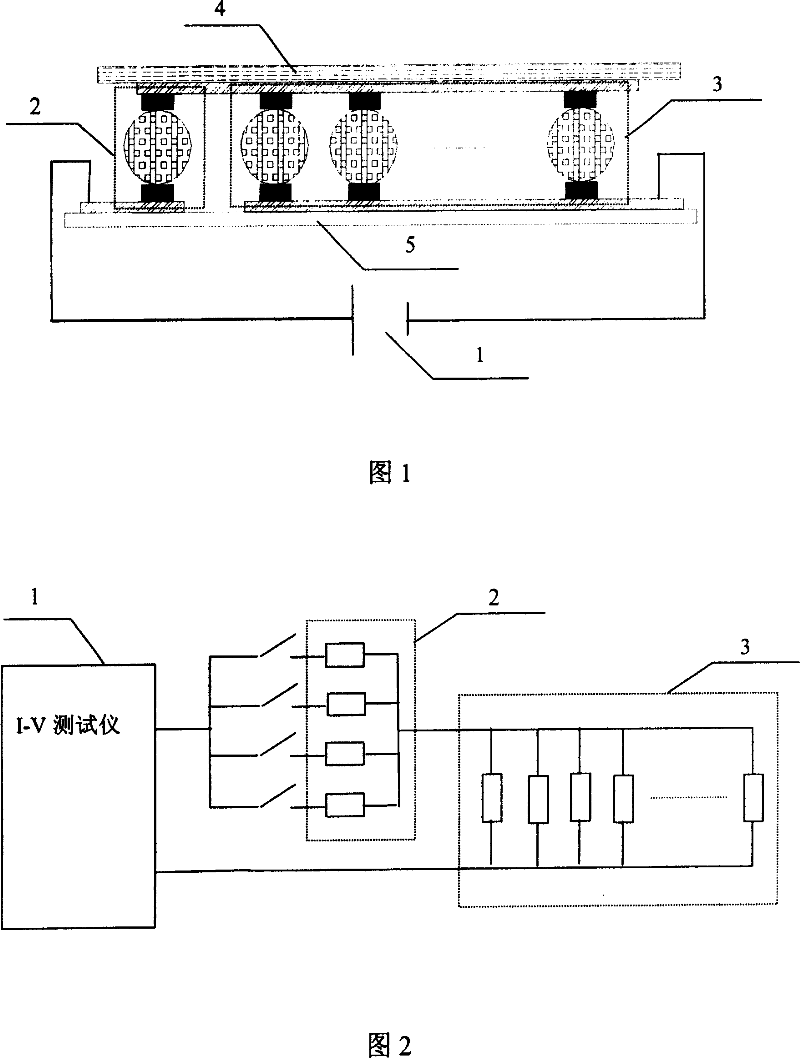

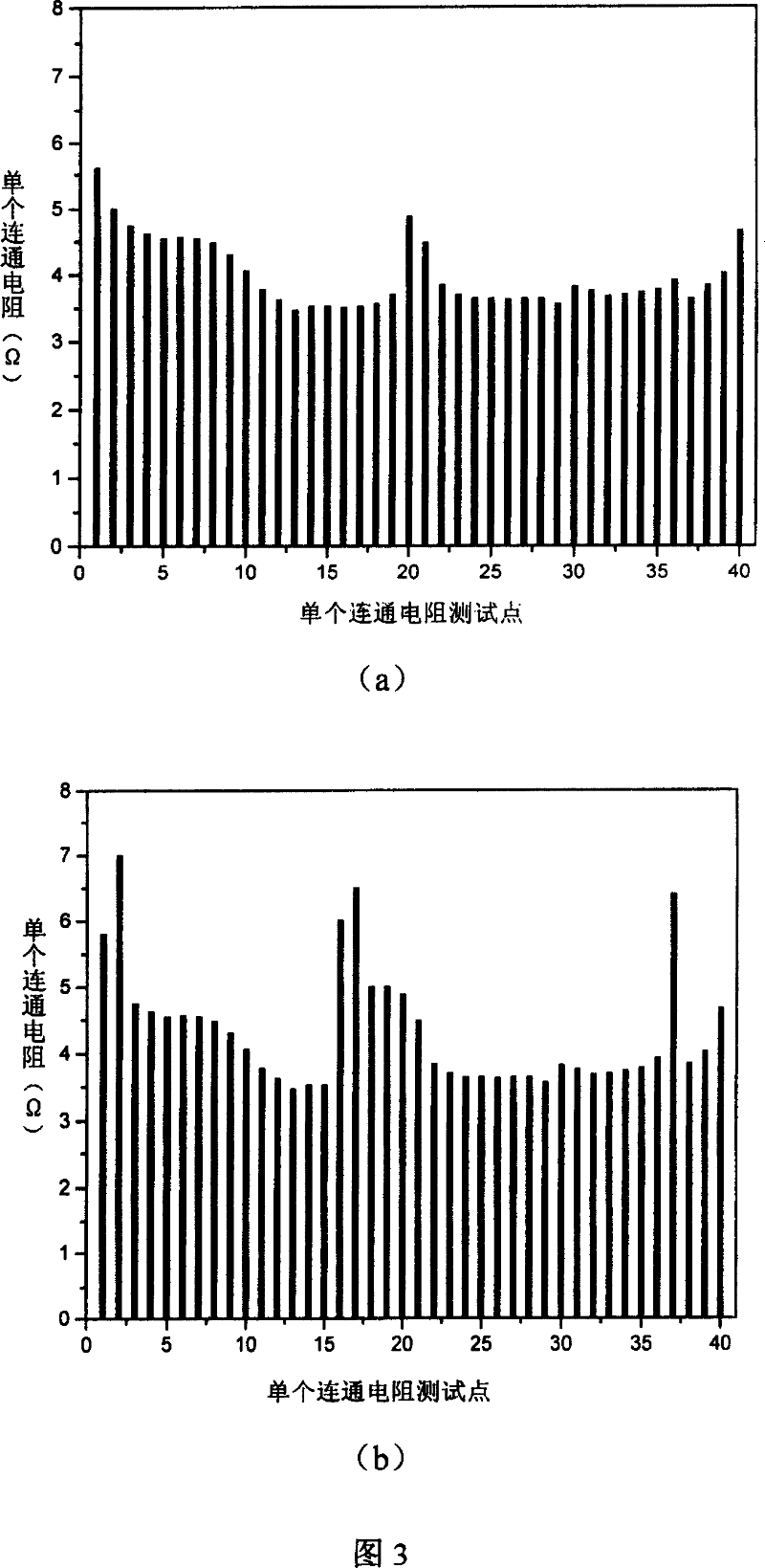

[0025] The present invention takes the HgCdTe infrared focal plane detector as an embodiment, and the HgCdTe infrared photosensitive element array chip 4 on the GaAs substrate has an area of 4×6mm 2 , The base area of the Si-based readout circuit 5 is 6×9mm 2 . When designing the device, 40 In bumps were added at equal intervals around the photosensitive element array chip, and 40 In bumps were added correspondingly around the Si-based readout circuit. These added In bumps can be used in the preparation of light. The sensitive array chip and the readout circuit are manufactured by the way without increasing the manufacturing process steps and complexity of the device. When the light-sensitive array chip and the readout circuit are interconnected by reverse welding, the In bumps added between the four sides constitute 40 single connected resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com