Pendulum type on-off valve

An on-off valve and pendulum technology, applied in the field of high, medium and low pressure liquid flow pipelines, can solve problems such as leakage and easy wear and tear, and achieve the effects of high transmission efficiency, large force multiplier and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

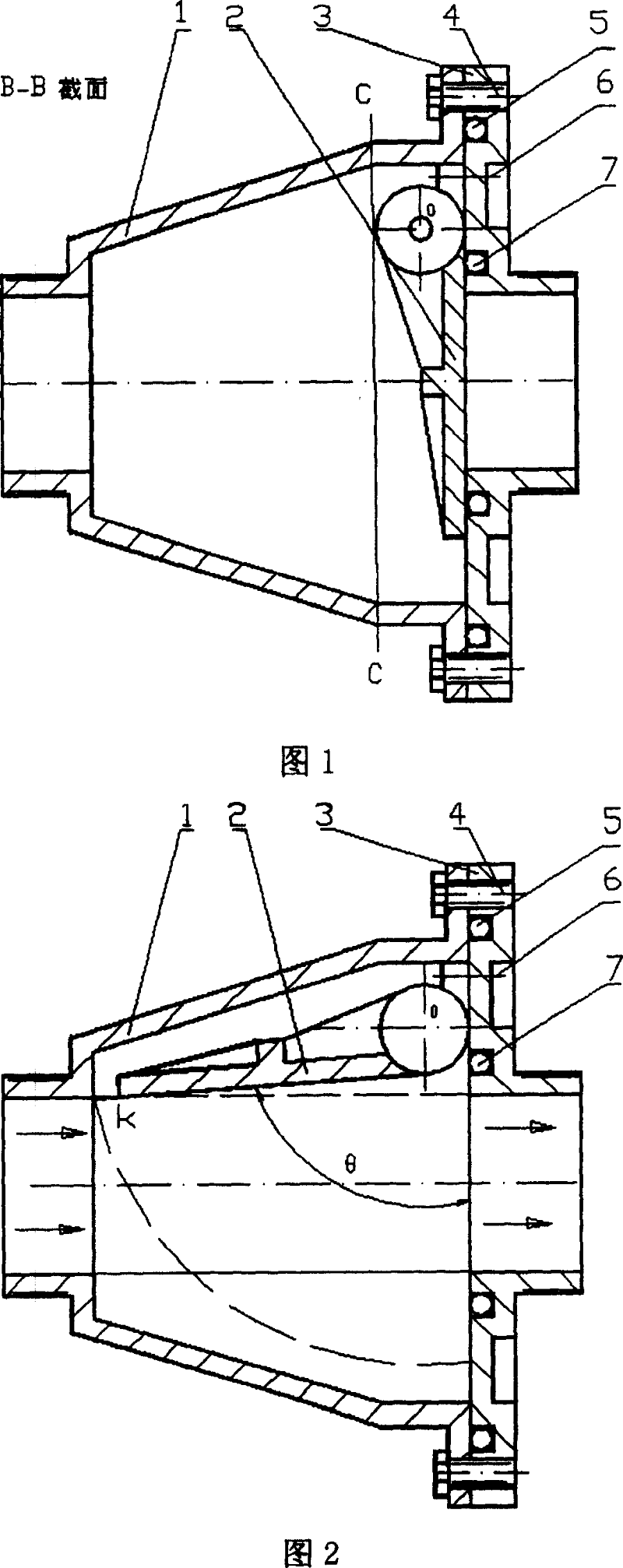

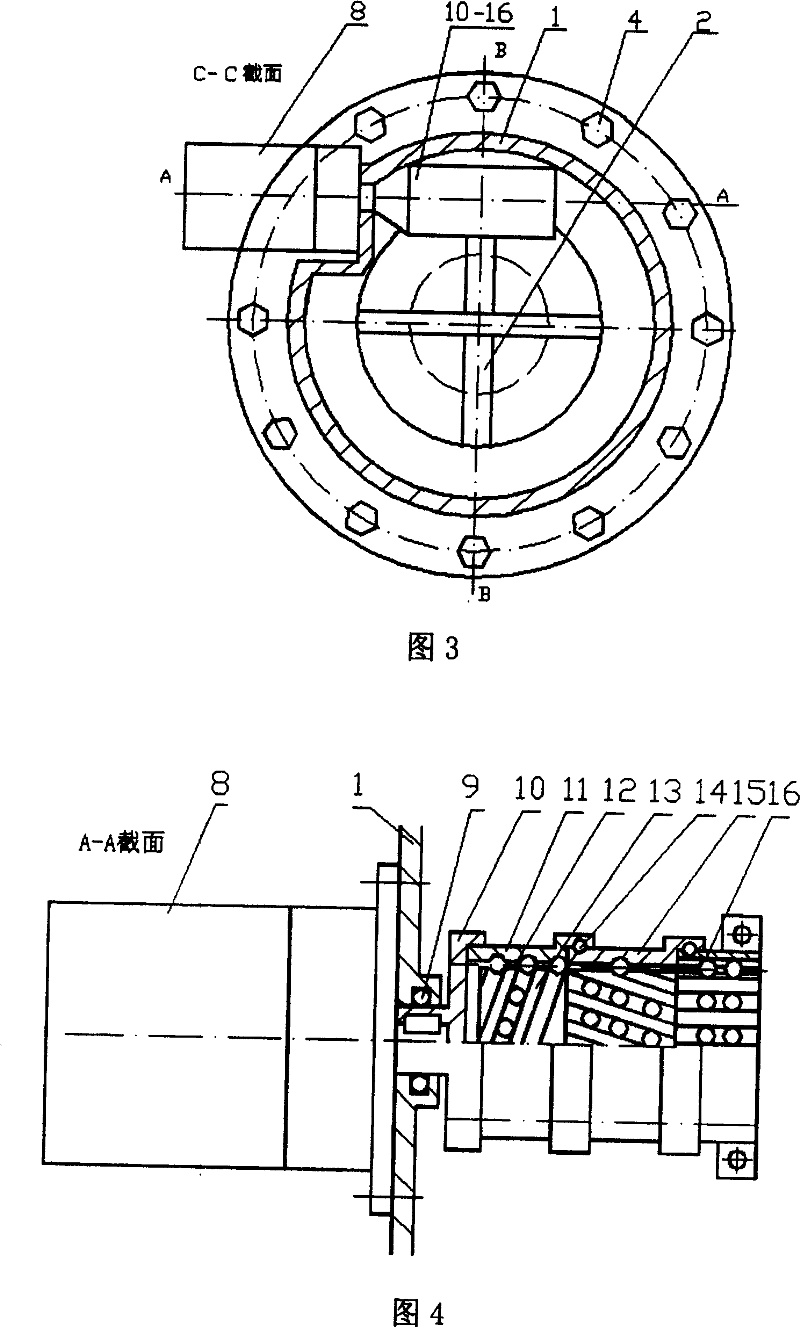

[0013] See the accompanying drawings: the pendulum switch valve in the figure includes a valve body 1, a switch valve 2, and a valve cover 3; wherein: the switch valve adopts a rotary valve that rotates around an axis outside the inner diameter, so that when the valve is fully opened, the inner diameter of the switch valve passes And the direction is completely consistent with the pipe hole; the valve is driven by a double-helix drive mechanism, which includes a motor 8, a screw 13 with a large-swing angle helical groove section, a small-swing angle helical groove section and a spline groove section, A helical sleeve, a splined sleeve and two thrust bearings (14) respectively corresponding to the helical groove section and the spline groove section, wherein the helical sleeve with a small rotation angle is keyed to the motor shaft installed outside the valve body through the end cover , there are thrust bearings 14 between the high-swing angle helical sleeve and the small-swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com